Ultralow-temperature in-situ stretching table and scanning electron microscope ultralow-temperature in-situ stretching test system

A technology of in-situ stretching and scanning electron microscopy, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve problems such as fracture, dynamic capture of material crack initiation, etc., and achieve precise control and visual representation And the effect of wide applicability and precise temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

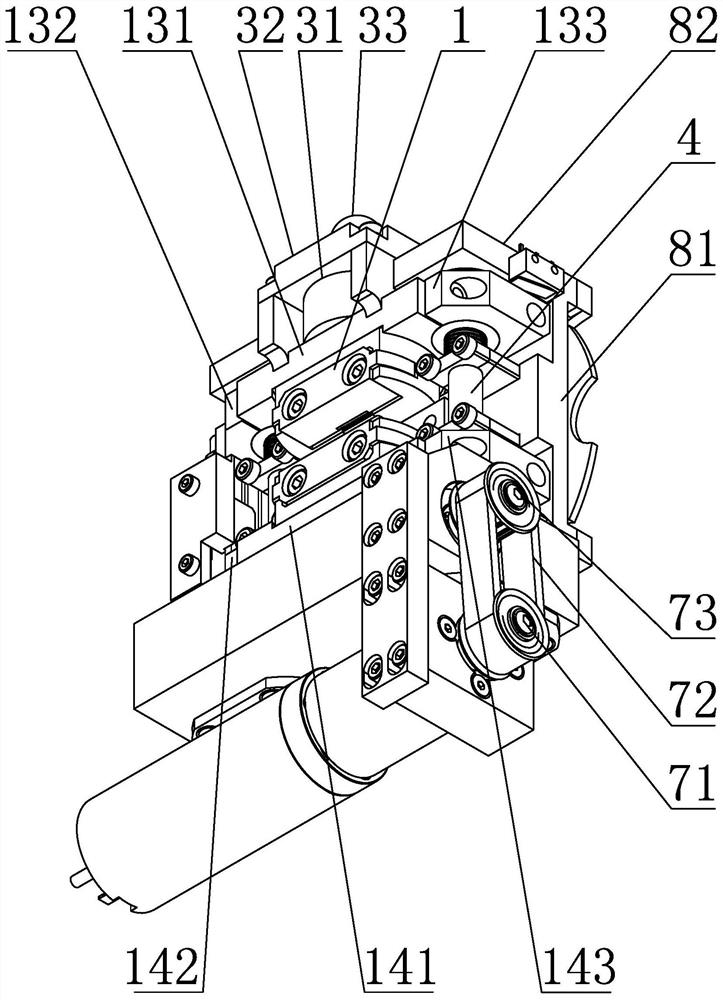

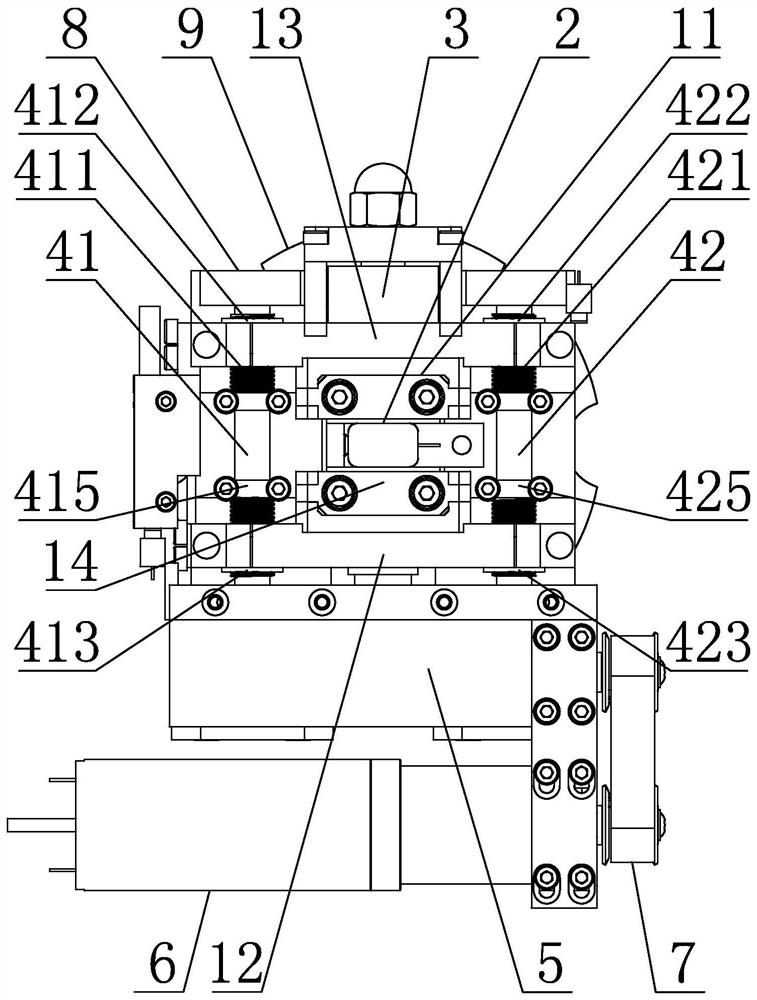

[0028] Specific implementation mode one: combine Figure 2 to Figure 9 Describe this embodiment, an ultra-low temperature in-situ stretching table of this embodiment, which includes a sample holder 1, a cryogenic refrigerator 2, a tension sensor assembly 3, a moving screw mechanism 4, a driving device, a frame 8 and an electron microscope The platform connection plate 9 and the frame 8 include a base plate 81 and two side plates 82, the base plate 81 is arranged horizontally, and the two side plates 82 are vertically arranged on both sides of the upper end surface of the base plate 81, and the base plate 81 and the two side plates 82 are integrated structure, each side plate 82 is provided with two shaft holes reserved for screw screws, and the four shaft holes reserved for screw screws on the two side plates 82 are arranged opposite to each other. The device 2 is installed in the reserved square hole of the refrigerator of the base plate 81, and the electron microscope stage ...

specific Embodiment approach 2

[0029] Specific implementation mode two: combination Figure 6 to Figure 9 Describe this embodiment, the driving device of this embodiment comprises speed reducer 5, motor 6 and belt transmission mechanism 7, speed reducer 5 is installed on the outer end surface of a side plate 82 of frame 8, two output shafts of speed reducer 5 Connect with the first lead screw assembly 41 and the second lead screw assembly 42 respectively, the motor 6 is installed on the speed reducer 5, the belt transmission mechanism 7 includes a driving pulley 71, a conveyor belt 72 and a driven pulley 73, and the driving pulley 71 is installed On the output shaft of the motor 6 , the driven pulley 73 is installed on the input shaft of the speed reducer 5 , and the driving pulley 71 is connected with the driven pulley 73 through the transmission belt 72 . In this way, the output shaft of the motor 6 drives the driving pulley 71 to rotate, and the driving pulley 71 drives the driven pulley 73 to rotate thr...

specific Embodiment approach 3

[0030] Specific implementation mode three: combination Figure 2 to Figure 5 To illustrate this embodiment, the first screw assembly 41 of this embodiment includes a screw shaft a411, an upper slider a412, a lower slider a413, two bearings a414 and two screw support seats a415, and the two screw shafts a411 The ends are respectively inserted into the reserved shaft holes of the screw corresponding to the two side plates 82, the bearing a414 is provided between the shaft end of the screw shaft a411 and the corresponding side plate 82, and the two ends of the screw shaft a411 are respectively provided with left-handed threads and right-handed thread, the middle part of the screw shaft a411 is the optical axis, the upper slider a412 and the lower slider a413 are screwed on the two ends of the screw shaft a411 respectively, and the two screw support seats a415 are sleeved on the screw shaft a411 The middle optical axis is connected with the bottom plate 81; the second screw assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com