Method for continuously and stably recovering aniline in aniline wastewater

A kind of technology of aniline wastewater and aniline, applied in amino compound purification/separation, organic chemistry, etc., can solve the problems of high aniline low boiling content, control index off-label alarm, and affect product quality, so as to reduce the moisture content and eliminate the impact , to ensure the effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

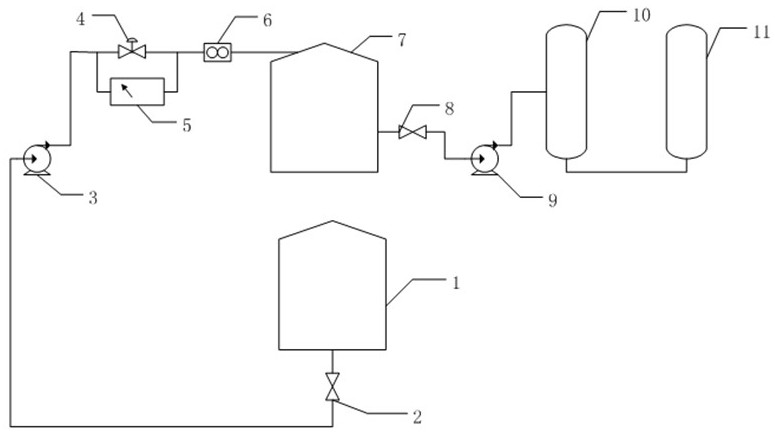

Image

Examples

Embodiment 1

[0028] Discharging valve Ⅰ at the lower part of the aniline wastewater tank, start the centrifugal pump Ⅰ, open the outlet valve Ⅱ of the centrifugal pump, and recover crude aniline from the crude aniline tank. When the conductivity meter shows 0.020s / m, stop the recovery and analyze the crude aniline The water content in the tank was 1.81%.

Embodiment 2

[0030] Discharging valve Ⅰ in the lower part of the aniline wastewater tank, start the centrifugal pump Ⅰ, open the outlet valve Ⅱ of the centrifugal pump, and recover crude aniline from the crude aniline tank. When the conductivity meter shows 0.012s / m, stop the recovery and analyze the crude aniline The water content in the tank is 0.98%.

Embodiment 3

[0032] Discharging valve Ⅰ in the lower part of the aniline wastewater tank, start the centrifugal pump Ⅰ, open the outlet valve Ⅱ of the centrifugal pump, and recover crude aniline from the crude aniline tank. When the conductivity meter shows 0.008s / m, stop the recovery and analyze the crude aniline The water content in the tank was 0.76%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com