Negative carbon emission modified raw soil-based building block and manufacturing method thereof

A production method and technology of permanent soil, which is applied in the field of civil engineering building materials, can solve the problems of high cement pollution, high energy consumption, and long block forming time, so as to avoid environmental and economic problems, have broad application prospects, and ensure safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

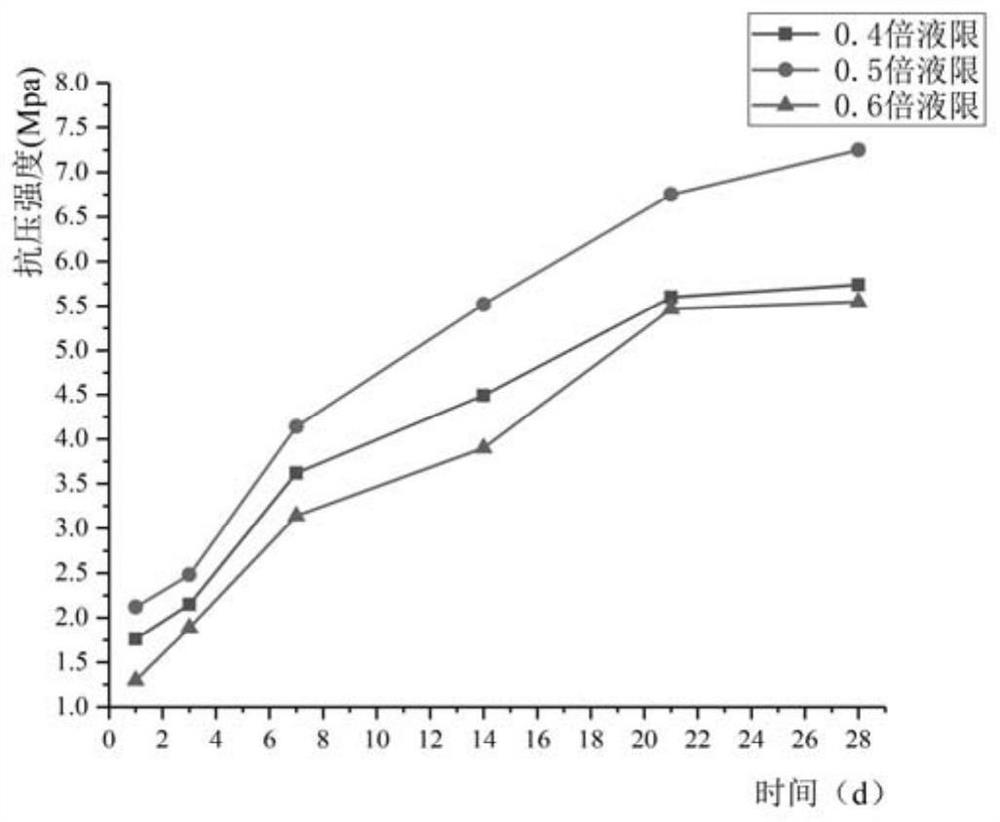

[0021] A modified raw soil-based building block with negative carbon emissions, including the following raw materials: 210g of activated magnesium oxide, 210g of cement, 180g of fly ash, 1800g of raw soil,

[0022] Then add 480g, 600g and 720g of water respectively and mix to obtain three kinds of modified raw soil-based materials with different tax rates.

[0023] The ordinary Portland cement is Conch Group Conch brand 32.5 grade ordinary Portland cement; the active magnesia is selected from Japan Shen brand high-activity magnesia 150. The raw soil is taken from the expansive clay in the Hefei area, and with reference to the requirements in the "Soil Engineering Test Method Standard" (GB / T50123-1999), the mechanical performance index, particle composition and chemical composition analysis of the raw soil base material are tested respectively. To avoid the large particles in the soil material from affecting the accuracy of the test results, the natural raw soil was dried, crus...

Embodiment 2

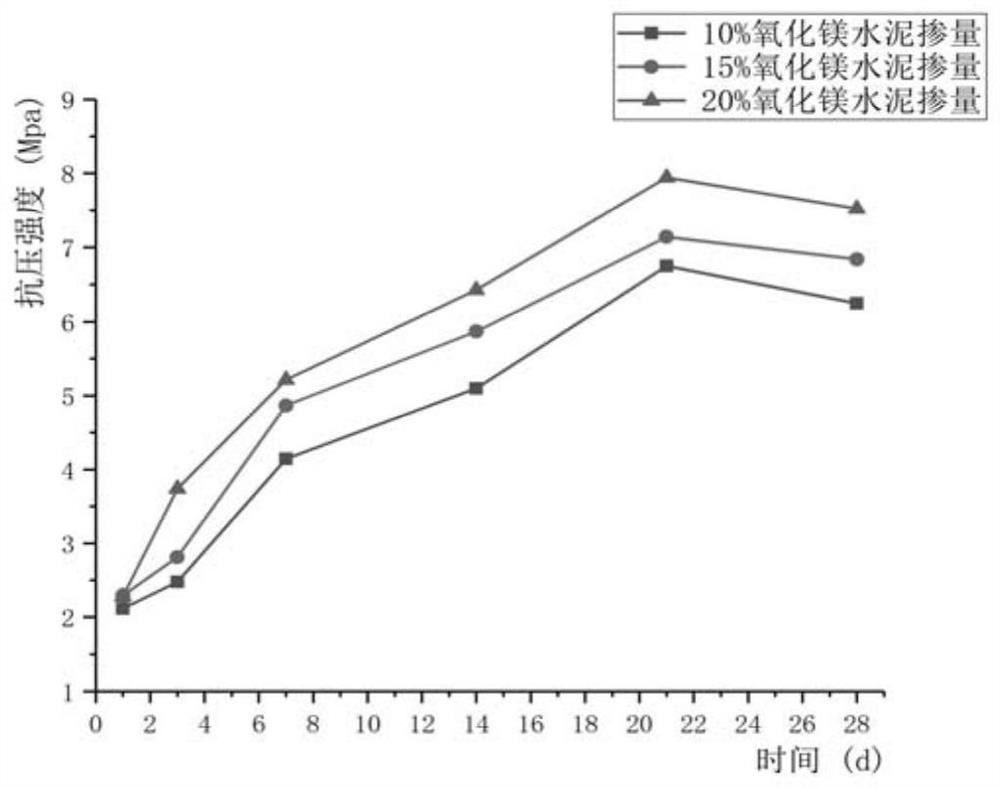

[0029] A modified raw soil-based building block with negative carbon emission, comprising the following raw materials: 120g of activated magnesium oxide, 120g of cement, 60g of fly ash, 2100g of raw soil, and 600g of water.

[0030] A method for making a modified raw soil-based building block with negative carbon emissions. The above-mentioned modified raw soil-based materials are mixed and stirred evenly and injected into a mold with a length of 150 mm, a width of 150 mm, and a height of 150 mm for vibration, and a jack After pressing, the raw soil blocks were pressed at a pressing rate of 0.2kN / s during the pressing process and held at 5Mpa, 8Mpa, and 10Mpa for 10s to be pressed and formed. After molding, put it into a carbonization box for carbonization treatment. The parameters of the carbonization box are controlled at a temperature of 20°C, a humidity of 60%, and CO 2 The concentration is 30%, and the ventilation pressure is 100kpa. After carbonization for 21 days, the ...

Embodiment 3

[0032] A modified raw soil-based building block with negative carbon emission, comprising the following raw materials: 180 g of activated magnesium oxide, 180 g of cement, 90 g of fly ash, 1950 g of raw soil, and 600 g of water.

[0033] A method for making a modified raw soil-based building block with negative carbon emissions. The above-mentioned modified raw soil-based materials are mixed and stirred evenly and injected into a mold with a length of 150 mm, a width of 150 mm, and a height of 150 mm for vibration, and a jack After pressing, the raw soil blocks were pressed at a pressing rate of 0.2kN / s during the pressing process and held at 5Mpa, 8Mpa, and 10Mpa for 10s to be pressed and formed. After molding, put it into a carbonization box for carbonization treatment. The parameters of the carbonization box are controlled at a temperature of 20°C, a humidity of 60%, and CO 2 The concentration is 30%, and the ventilation pressure is 100kpa. After carbonization for 21 days,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com