Fruit core crisp production device and preparation process thereof

The invention relates to a production device and a technology for fruit cakes, which are applied in the field of fruit cakes production devices and their preparation technology, and can solve the problems affecting the preparation efficiency of fruit cakes, the loss of the nutritional value of fruits, affecting the appetite of consumers, etc., so as to retain the nutritional value and improve the Appetite, efficiency-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A kind of core crisp preparation technology is characterized in that, comprises the steps:

[0039] S1: Making fillings: choose an appropriate amount of sunflower seeds, place the sunflower seeds in a stir-frying device to fry the oil, take a certain amount of fruit pulp and crush it with a crushing device, add it to the sunflower oil after crushing, stir-fry, and add water Make puree, then add appropriate amount of stevia, angelica, ginseng and white sugar, boil, boil for 40 minutes, cool down and add appropriate amount of edible organic acid, wax gourd puree and rose sauce, stir well and continue to boil Cook for 5 minutes, add an appropriate amount of frozen powder and edible salt to the boiled liquid and stir evenly. After cooling, put it in a refrigerator for refrigeration;

[0040]S2: Making fruit pigment and pectin: Take the inner peel of the fruit and boil it in water for 10 minutes to inactivate the enzyme, inactivate the polyphenol oxidase in the peel, remove ...

Embodiment 2

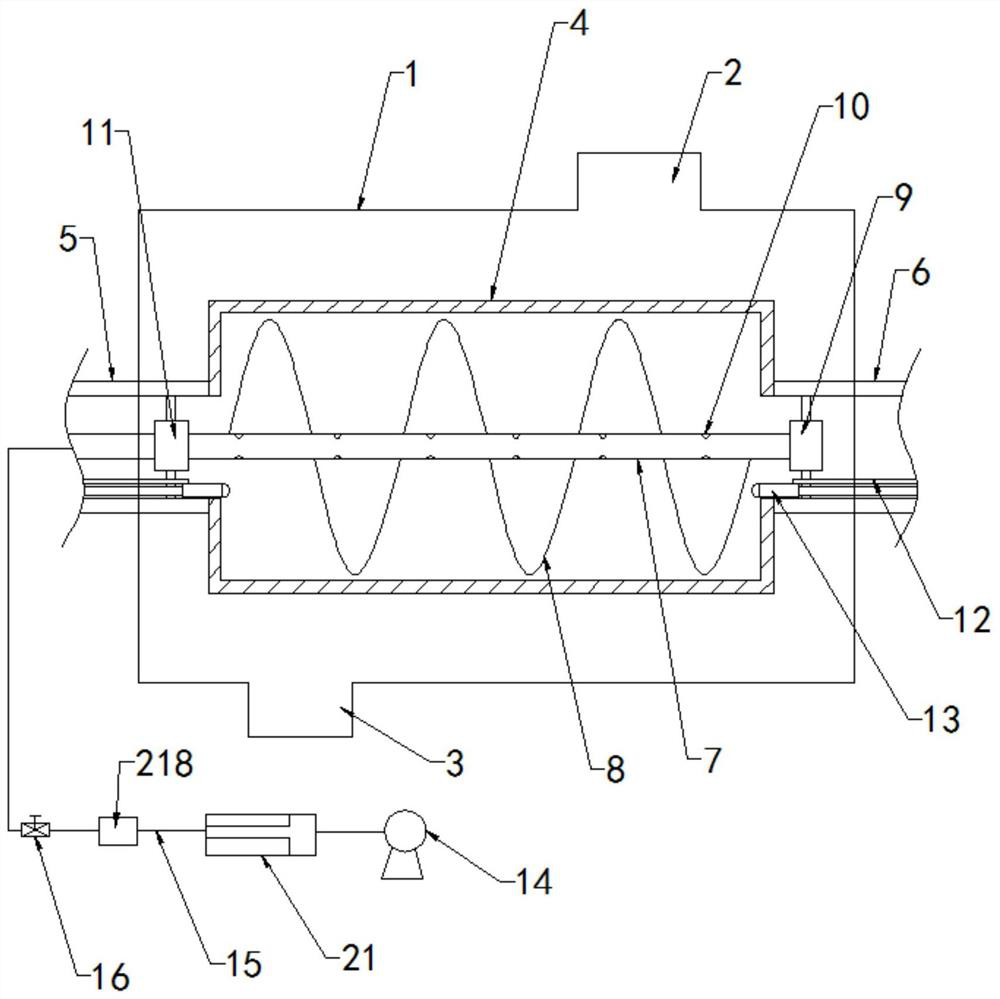

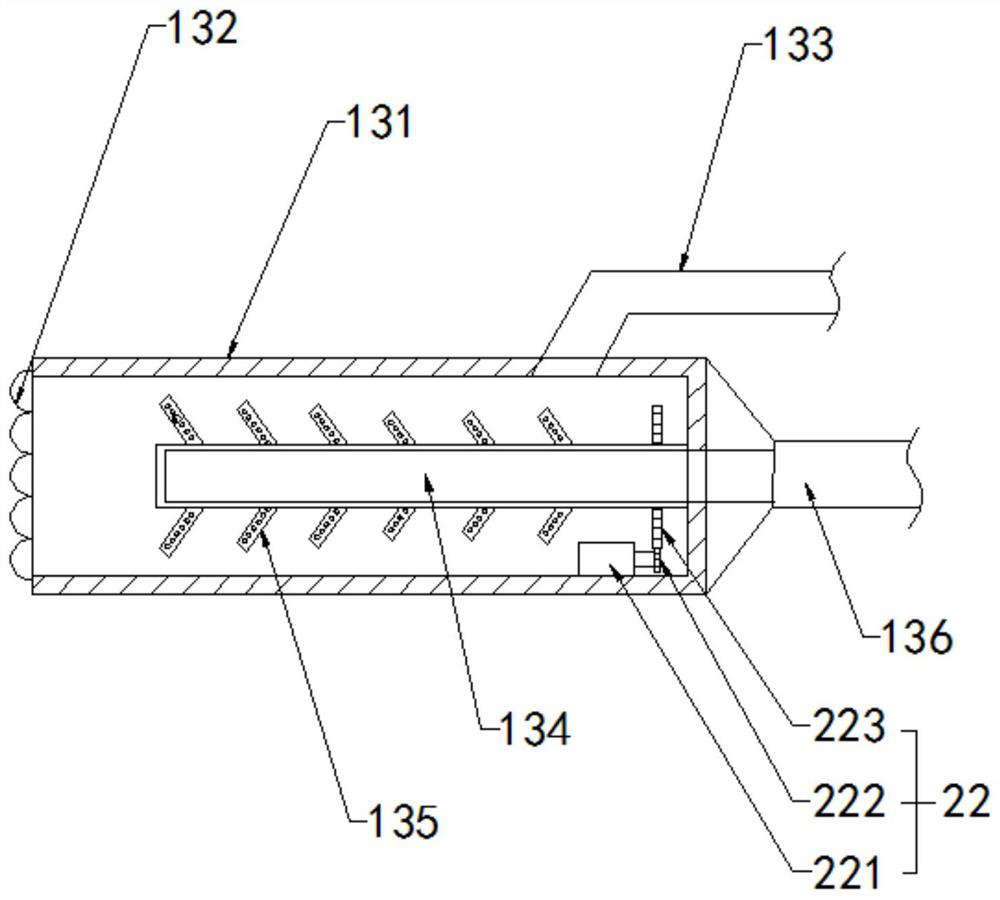

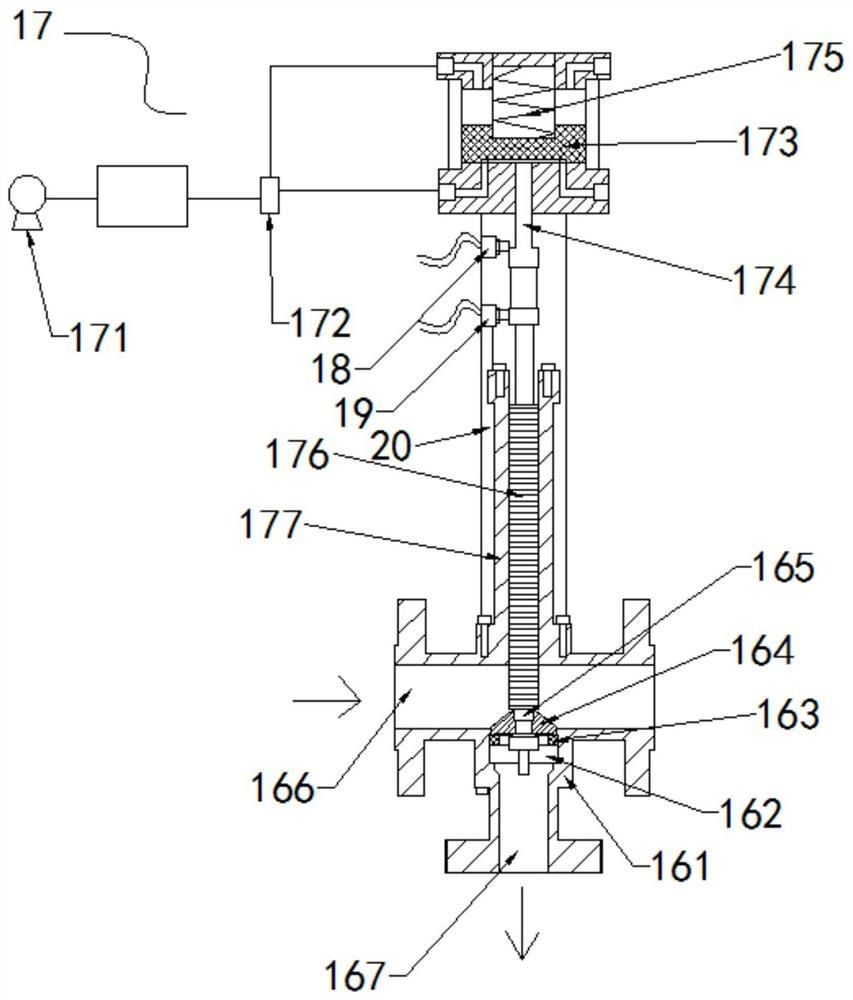

[0044] Such as figure 1 As shown, the present invention discloses a fruit core crisp production device. In the specific embodiment of the present invention, it includes a stir-frying device, a crushing device, a mixing and stirring device, a stirring and evaporating device, a refrigeration device, a vacuum filter, an extraction device, Mold and oven, described stirring evaporating device comprises first stirring evaporating device and second stirring evaporating device, described first stirring evaporating device and second stirring evaporating device are connected, and described first stirring evaporating device is used for filtrate stirring Evaporate into a high-concentration mixed liquid, and the second stirring and evaporating device is used to mix and evaporate the high-concentration crystalline component powder obtained by the first stirring and evaporating device; the first stirring and evaporating device includes a heating chamber 1 and is installed in the heating chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com