Cylinder bore inner surface inspection method and inspection device

An inspection method and inspection device technology, applied in the direction of measuring devices, optical devices, optical testing flaws/defects, etc., can solve the problems of difficult insertion of mirrors, difficulty in obtaining clear images, etc., and achieve the effect of avoiding halo

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

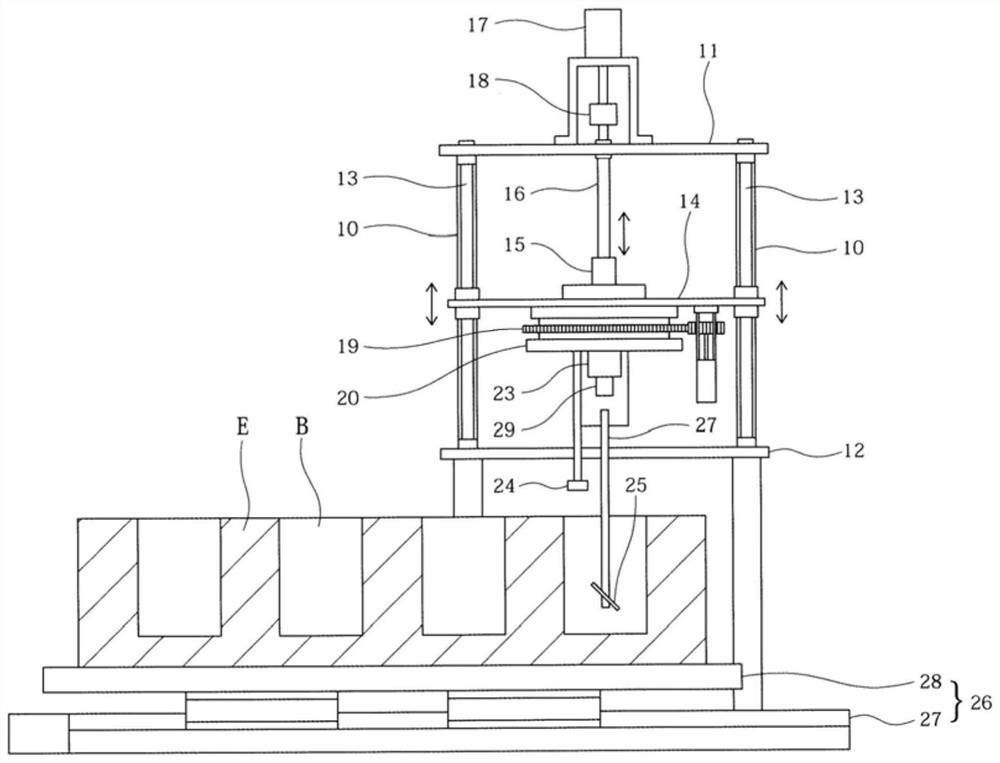

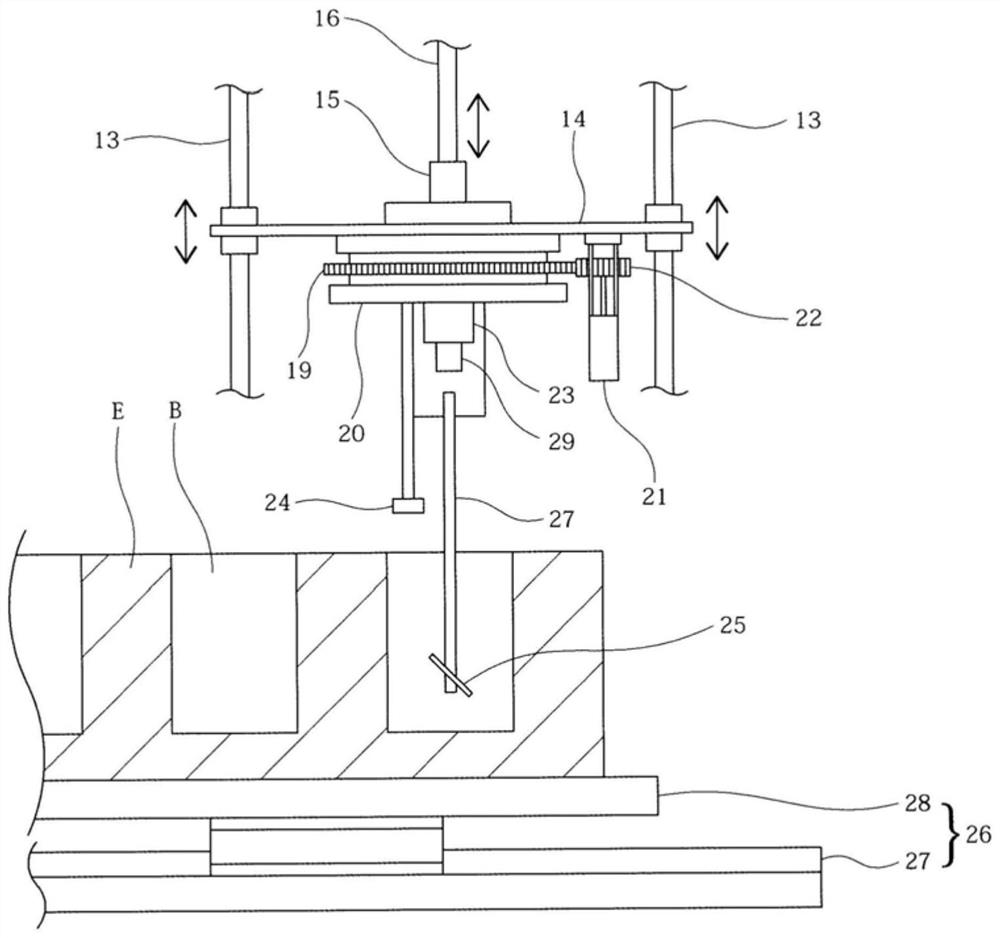

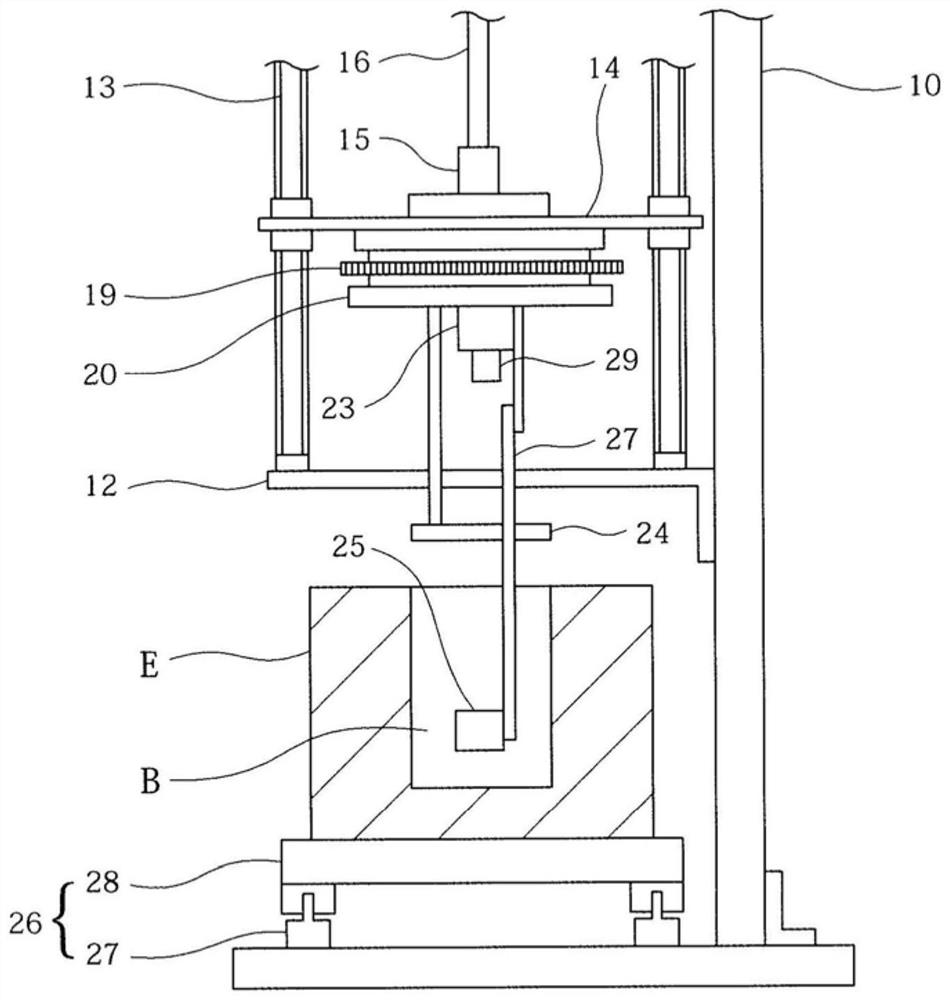

[0027] figure 1 It is an overall view showing the inspection device of the inner surface of the cylinder bore according to the embodiment. 10 is a pair of left and right pillars, 11 is an upper frame supported by the pair of pillars 10, and 12 is a lower frame. A plurality of guide columns 13 are provided between the upper frame 11 and the lower frame 12. 14 is a flat plate-shaped elevating frame, and the elevating frame 14 is guided by the guide columns 13 so as to be raised and lowered while maintaining a horizontal posture.

[0028] A nut 15 is fixed to the upper surface of the elevating frame 14 , and a feed screw 16 vertically provided between the upper frame 11 and the lower frame 12 passes through the nut 15 . The feed screw 16 is rotated in forward and reverse directions by an elevating motor 17 provided above the upper stage 11 , so that the elevating stage 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com