A remote wireless control system of a cutting and separating device and its application method

A technology of remote wireless and separation devices, which is applied in signal transmission systems, instruments, blasting, etc., and can solve problems such as loopholes, low security of wireless control systems, and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1, the state check before use, includes the following steps:

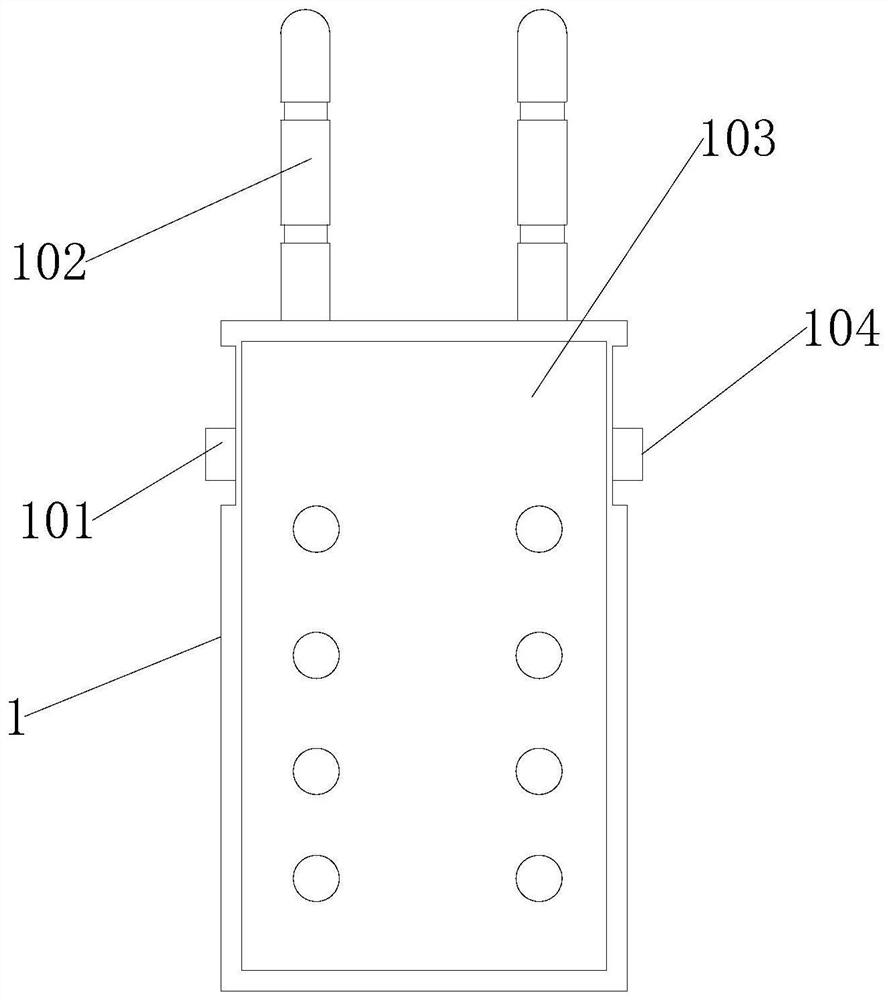

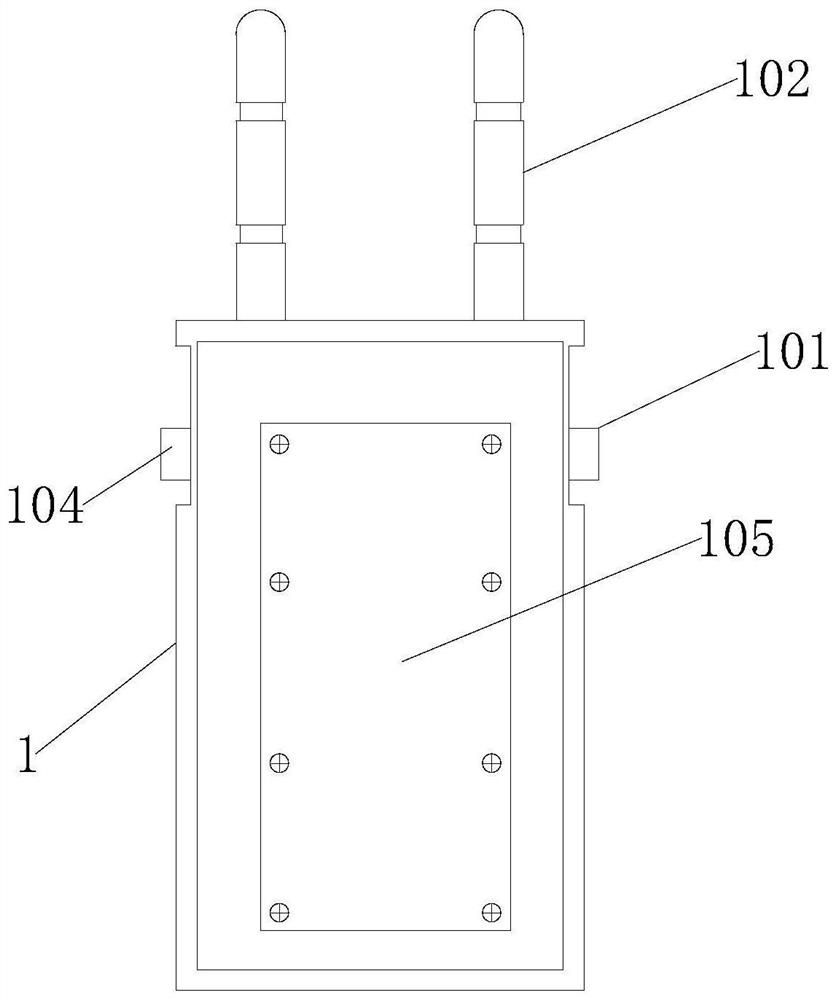

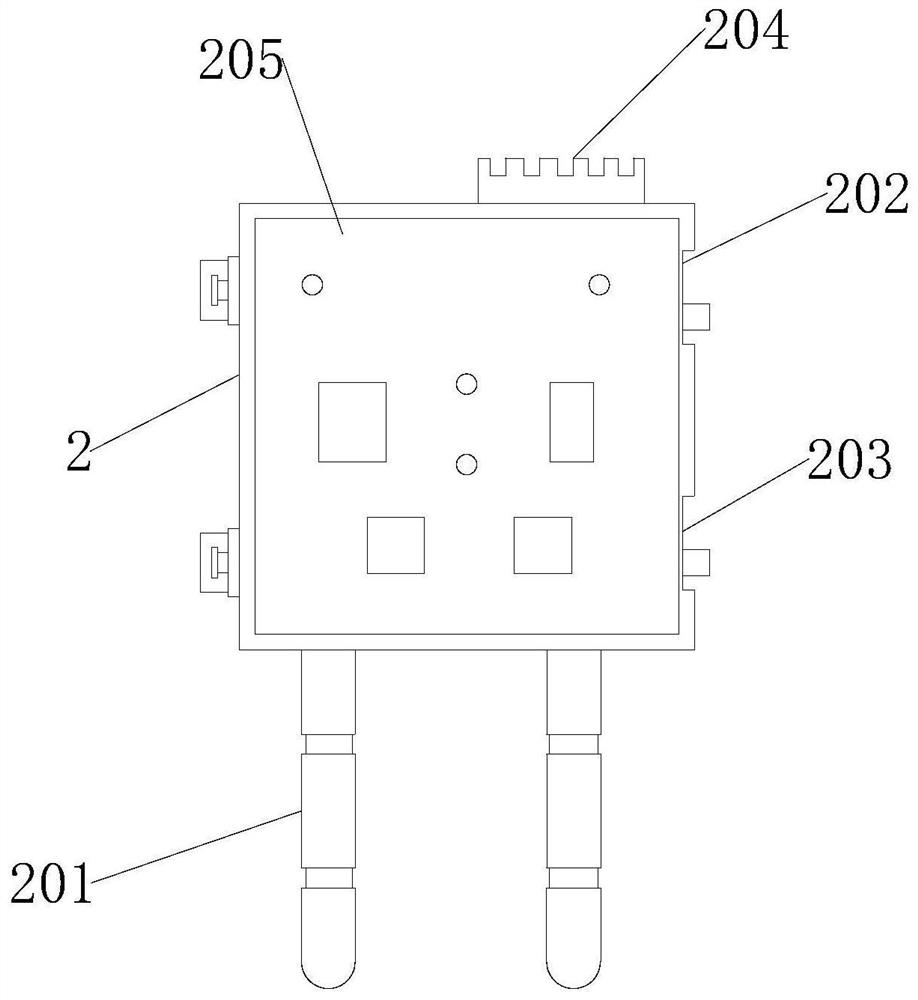

[0042] Step 1, first check whether the antenna installation of signal transmitter 1 or signal receiver 2 is normal, and the antenna should not be loose, fall off, or not installed properly;

[0043] Step 2: Before turning on the power switch 1 101 of the signal transmitter 1 or the power switch 2 202 of the signal receiver 2, make sure that the enable switch 1 104 or the enable switch 2 203 is in the "off" position, that is, the switch direction is downward. ;

[0044]Step 3, then carry out the pyrotechnic installation. It is strictly prohibited to perform the pyrotechnic installation operation when the power switch 202 or the enabling switch 203 of the signal receiver 2 is turned on. The pyrotechnic terminal 204 of the signal receiver 2 is divided into: For two groups, connect one pyrotechnic product each, peel off the lead end of the pyrotechnic product to expose 4-6mm of the wire core, press t...

Embodiment 2

[0045] Embodiment 2, using process operation, comprises the following steps:

[0046] Step one, power up

[0047] Turn on the power switch 1 101 of the signal transmitter 1 or the power switch 2 202 of the signal receiver 2, that is, the power switch 1 101 and the power switch 2 202 are pulled up, the system is powered on, the power indicator light is on, and after the self-test is passed, the power indicator light and one channel indicator is on, if enable switch one 104 or enable switch two 203 self-check fault, the power indicator, two channel indicators, and communication indicator are on, and the digital tube displays the number 8, please enable switch one 104 or enable switch two 203 is toggled downward. After toggle, the self-check fault state of enable switch one 104 or enable switch two 203 should disappear. If it does not disappear, please stop using the product. If the fault is detected, the power indicator and the communication indicator are on, and the power need...

Embodiment 3

[0058] Embodiment 3, battery replacement, including the following steps;

[0059] a First turn off the power switch one 101 and enable switch one 104 of the signal transmitter 1 or turn off the power switch two 202 and enable switch two 203 of the signal receiver 2;

[0060] b Then use a Phillips screwdriver to remove the cover of the battery compartment, and take out the old battery. Both the signal transmitter 1 and the signal receiver 2 are powered by two military AA batteries in parallel to ensure that the working time is longer than 24 hours. Use a multimeter to measure the battery voltage of the new battery, and the qualified voltage range is between 3.56V and 3.66V. After the test is qualified, install the new battery, and screw in the screw to fix the battery compartment cover, and the battery replacement is completed;

[0061] c After each battery replacement operation, it is necessary to clear the power record, turn on the power switch 1 101 or the power switch 2 202...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com