Biomass and coal co-gasification system and method

A biomass and co-gasification technology, applied in the field of gasification, can solve the problems of limiting biomass, pipeline blockage, and low gasification temperature, and achieve the effects of increasing the proportion of mesopores, promoting conversion, and improving gasification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

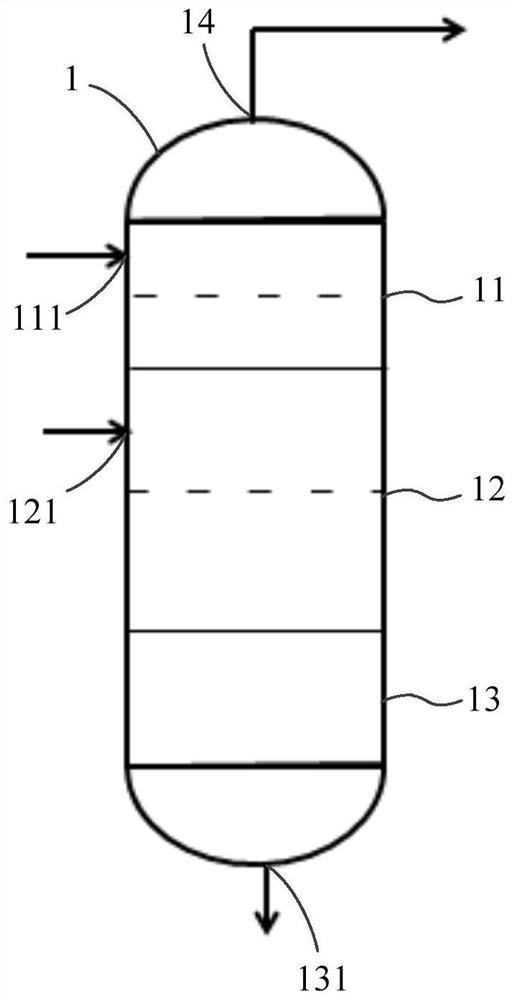

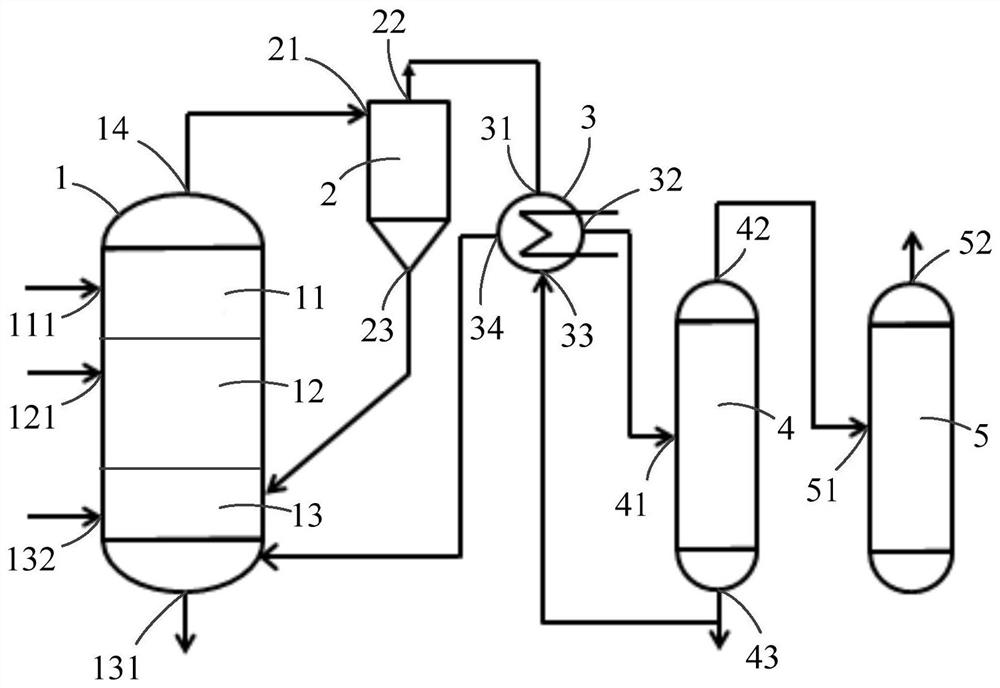

[0048] refer to figure 1 As shown, this embodiment provides a biomass and coal co-gasification system, the system specifically includes a gasifier 1 . The gasifier 1 is specifically a fluidized bed gasifier. The inner cavity of the gasifier 1 includes a pyrolysis zone 11 , a gasification zone 12 and a combustion zone 13 in sequence from top to bottom. It should be noted that the description from top to bottom here is based on the state of the gasifier 1 during specific use.

[0049] The pyrolysis zone 11 has a coal sample inlet 111 through which the coal sample can enter, so that the coal sample undergoes a pyrolysis reaction in the pyrolysis zone 11 to generate pyrolysis gas and pyrolysis tar. Among them, the gasification zone 12 is communicated with the pyrolysis zone 11, and the pyrolysis semi-coke produced by the reaction in the pyrolysis zone 11 can enter the gasification zone 12 from the pyrolysis zone 11, and the gasification zone 12 has a raw material for biomass to ...

Embodiment 2

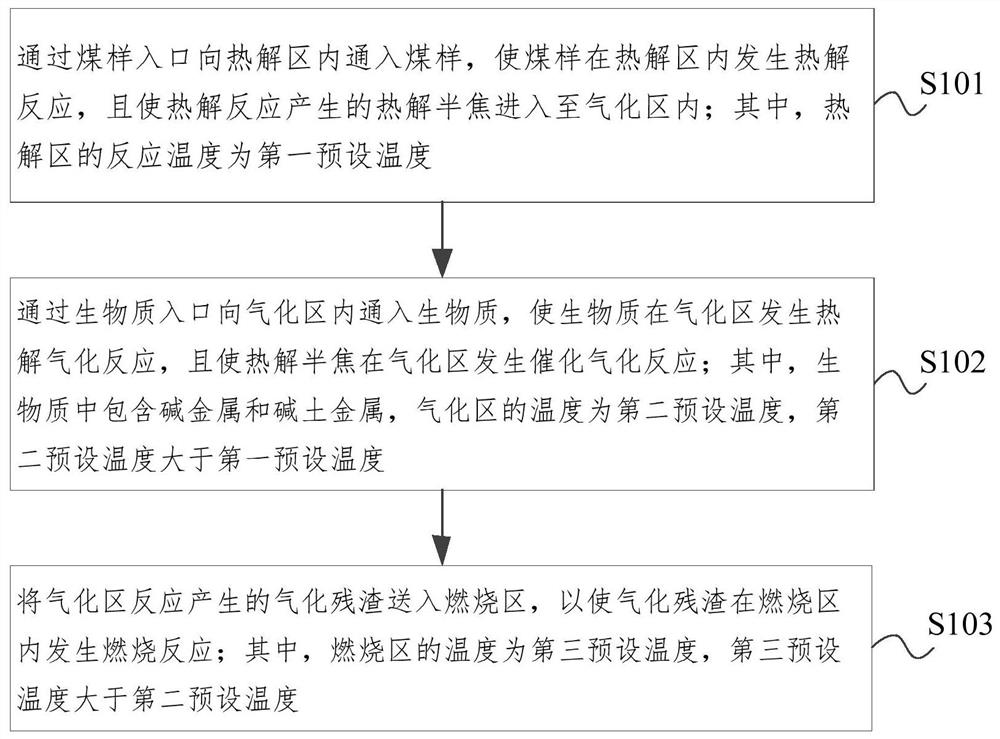

[0071] image 3 This is a schematic flowchart of the method for co-gasification of biomass and coal according to the embodiment of the present disclosure. refer to image 3 As shown, this embodiment also provides a method for co-gasification of biomass and coal, and the method can be implemented by part or all of the co-gasification system of biomass and coal provided in the above embodiment, so as to realize the co-gasification of biomass and coal. Co-gasification not only realizes the gasification of coal and biomass, but also plays the role of a catalyst in biomass, provides a cheap and disposable catalyst for coal gasification, and promotes the conversion of coal. produces tar.

[0072] combine Figure 1 to Figure 3 As shown, the method for the co-gasification of biomass and coal will be described below through specific embodiments, and the method specifically includes:

[0073] S101. Pass the coal sample into the pyrolysis zone through the coal sample inlet, so that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com