Preparation method and application of profile control agent

A technology of profile control agent and oxidant, which is applied in the direction of chemical instruments and methods, earthwork drilling, drilling composition, etc., can solve the problems that easily cause safety accidents, achieve no secondary pollution, mild reaction conditions, improve the adjustment The effect of sealing and channeling ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

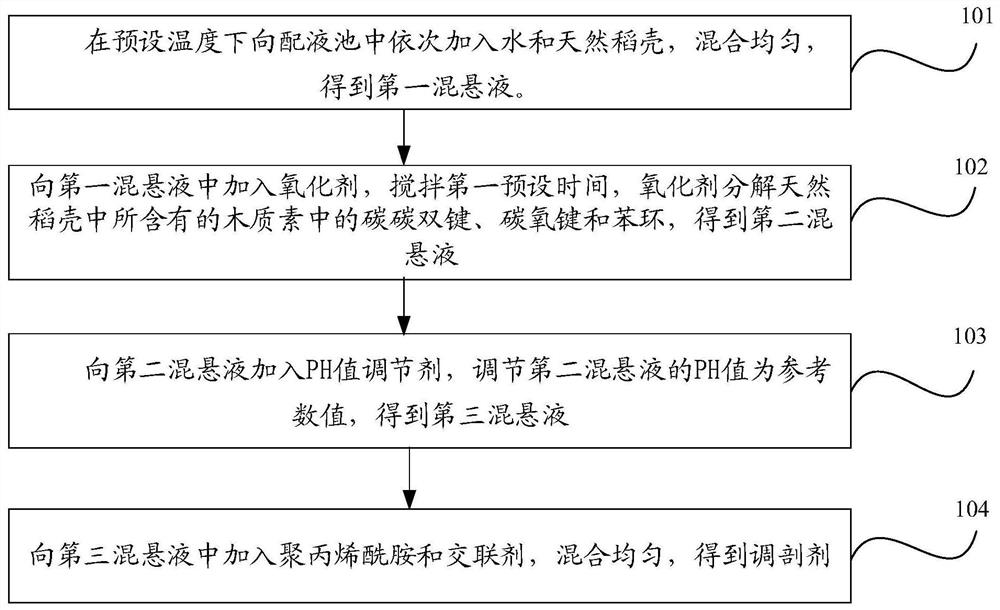

[0030] In a first aspect, an embodiment of the present invention provides a method for preparing a profile control agent, see figure 1 , the method includes:

[0031] Step 101 : adding water and natural rice husks to the liquid preparation tank in sequence at a preset temperature, and mixing them evenly to obtain a first suspension.

[0032] It should be noted that the preset temperature may be preset according to the usage requirements, for example, the preset temperature may be 15-25°C. For example, the preset temperature may be 15°C, 20°C, 25°C, or the like.

[0033] It should be noted that the mass ratio between water and natural rice husk may be 1:20-1:100, for example, the mass ratio of water and natural rice husk may be 1:20, 1:40, 1:60, 1:80 or 1:100 etc.

[0034] Step 102: adding an oxidant to the first suspension, stirring for a first preset time, the oxidant decomposes carbon-carbon double bonds, carbon-oxygen bonds and benzene rings in the lignin contained in th...

Embodiment 1

[0065] Add 20kg (kg) of water and 1kg of natural rice husks to the dosing tank at 25° C., mix well to obtain a first suspension; then feed into the first suspension with a concentration of 3mg / L of Ozone, and stir for 30min, ozone oxidation decomposes the lignin in the rice husk to obtain a second suspension, wherein the concentration of ozone is kept constant during the stirring process; then add citric acid to the second suspension, adjust the first suspension The pH value of the second suspension is 5.5 to obtain the third suspension; finally, 3g of partially hydrolyzed polyacrylamide and 3g of phenolic resin are added to 1kg of the third suspension, and the profile control agent is obtained by mixing uniformly.

[0066] After placing the profile control agent at a constant temperature of 60°C for 7 days, the viscosity of the profile control agent was measured with a DV-II viscometer, and the viscosity of the profile control agent was found to be 8450 mPa.s (mPa.s).

Embodiment 2

[0072] Add 60kg of water and 1kg of natural rice husks to the dosing tank in turn at 25°C, mix well to obtain a first suspension; then inject ozone with a concentration of 16mg / L into the first suspension, and Stirring for 75min, ozone oxidation decomposes the lignin in the rice husk to obtain a second suspension, wherein the concentration of ozone is kept constant during the stirring process; then citric acid is added to the second suspension to adjust the second suspension The pH value of the liquid is 5.5 to obtain the third suspension; finally, 3g of partially hydrolyzed polyacrylamide and 3g of phenolic resin are added to 1kg of the third suspension, and the profile control agent is obtained by mixing uniformly.

[0073] After placing the profile control agent at a constant temperature of 60°C for 7 days, the viscosity of the profile control agent was measured with a DV-II viscometer, and the viscosity of the profile control agent was found to be 11184 mPa.s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com