High-safety trailer special for steel coil transportation

A technology of safety performance and steel coil, which is applied in the direction of coil unit transportation, transportation and packaging, and vehicles used for freight transportation, etc. It can solve the problems of broken steel coils, troubles, and complicated fixing methods, etc. The effect of safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

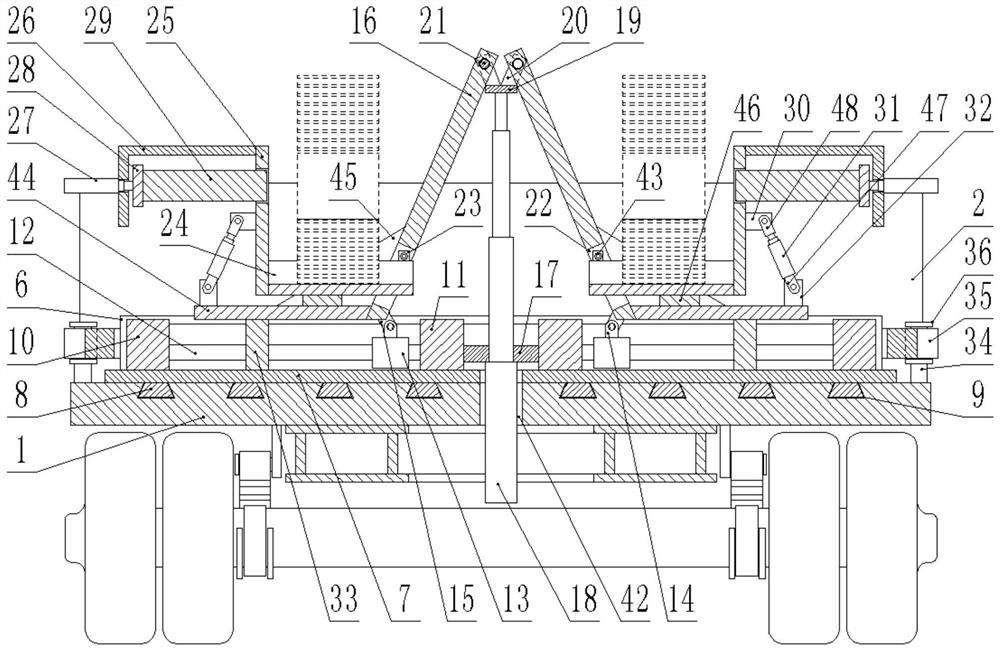

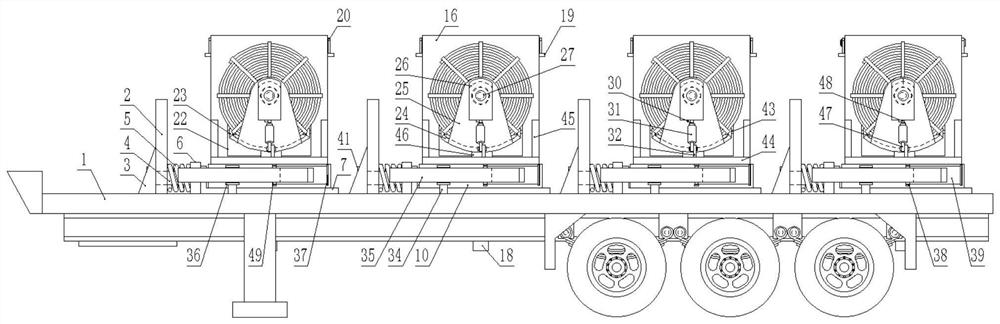

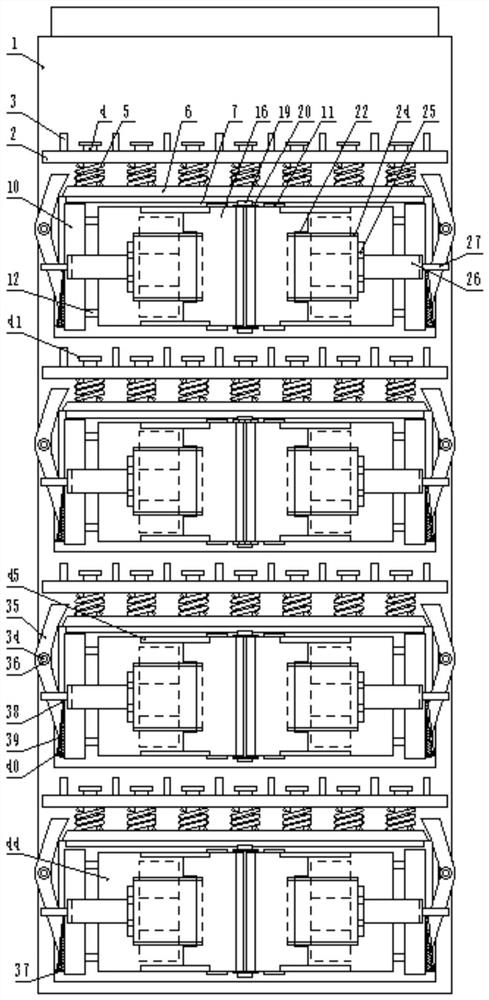

[0019] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6As shown, a special trailer for steel coil transportation with high safety performance includes a trailer body 1, and a plurality of risers 2 are evenly fixed on the top surface of the bottom plate of the trailer body 1, and one side of the riser 2 is connected to the trailer body. Several ribs 3 are uniformly fixed between the top surfaces of the vehicle floor of the main body 1, and several sliding rods 4 are horizontally penetrated at the bottom of the side wall of the vertical board 2, and the contact points between the sliding rods 4 and the vertical board 2 Sliding connection, one end of several slide bars 4 is respectively fixed with a stopper 41, and the other end of several slide bars 4 is fixed with the same horizontal plate 6, the end surfaces on both s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com