A Composite Membrane for Improving the Permeability of Polyamide Nanofiltration Composite Membrane and Its Preparation

A composite membrane, polyamide technology, applied in reverse osmosis, membrane technology, semi-permeable membrane separation and other directions, to achieve the effect of being conducive to large-scale production and application, the preparation and modification process is simple and easy to operate, and the permeability and selectivity are improved.

Active Publication Date: 2022-05-31

DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] In view of the problems existing in the above-mentioned technologies, the present invention provides a method for preparing a polyamide nanofiltration composite membrane with high permeation selectivity, and at the same time improves the water penetration and salt retention performance of the polyamide composite membrane to solve the problem of traditional polyamide nanofiltration composite membranes. One of the main problems with membranes

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

[0045]

[0048]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

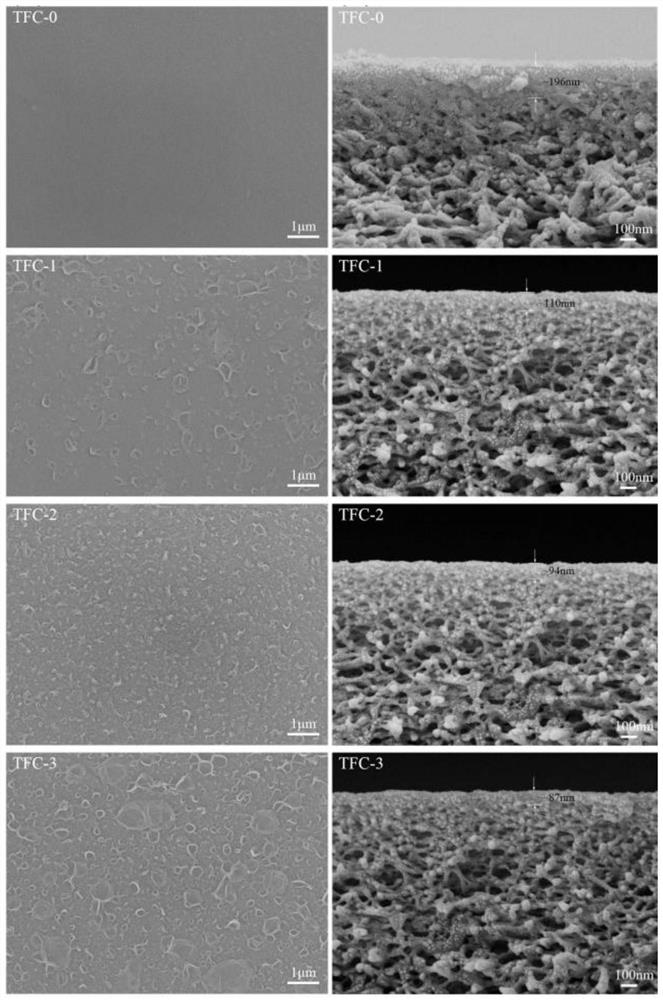

The invention relates to a polyamide nanofiltration composite membrane and a preparation process thereof. The composite membrane is composed of a non-woven base layer, a polymer mechanical support layer and a modified polyamide active separation layer. The feature of the present invention is that by introducing an inhibitor containing a single reactive group into the organic phase, the inhibitor can only react with polyamine monomers but cannot form a three-dimensional cross-linked structure with it because it has only a single reactive group, It inhibits the growth of polyamide chains and changes the network structure of the polyamide active separation layer; at the same time, the reaction process between the inhibitor and the polyamine monomer will generate hydrophilic groups, thereby changing the chemical properties and surface characteristics of the polyamide active separation layer , and finally greatly improve the brine separation performance of the polyamide nanofiltration composite membrane, that is, the permeation selectivity. The modification method has remarkable effect, does not need subsequent treatment process, and is easy to realize industrial scale-up and large-scale production application.

Description

A composite membrane for improving the permeability selectivity of a polyamide nanofiltration composite membrane and its preparation technical field The present invention relates to a kind of preparation technology of functional polymer membrane, relate more specifically to a kind of high permeability selectivity The polyamide nanofiltration composite membrane and its preparation. Background technique Thin film composite membrane (TFC membrane) with polyamide active layer is one of the most widely used polymer separation membranes. One, generally consists of polyester base layer, microfiltration or ultrafiltration polymer support layer and polyamide active separation thin layer, wherein polyester base layer And the polymer support layer is mainly used to improve the mechanical properties of the membrane, and the polyamide active layer plays the main separation role. dense poly The amide thin layer is formed by the polyamine monomer in the aqueous phase and the polya...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B01D67/00B01D61/02B01D69/10B01D69/12B01D71/56B01D65/10

CPCB01D69/12B01D71/56B01D61/027B01D69/10B01D69/125B01D65/10Y02A20/131

Inventor 曹义鸣秦倚天康国栋于海军

Owner DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com