Lithium battery heat dissipation equipment

A heat dissipation device and lithium battery technology, applied in the direction of secondary batteries, battery pack components, circuits, etc., can solve the problems of unfavorable use of new energy vehicles, long time consumption, low heat dissipation efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

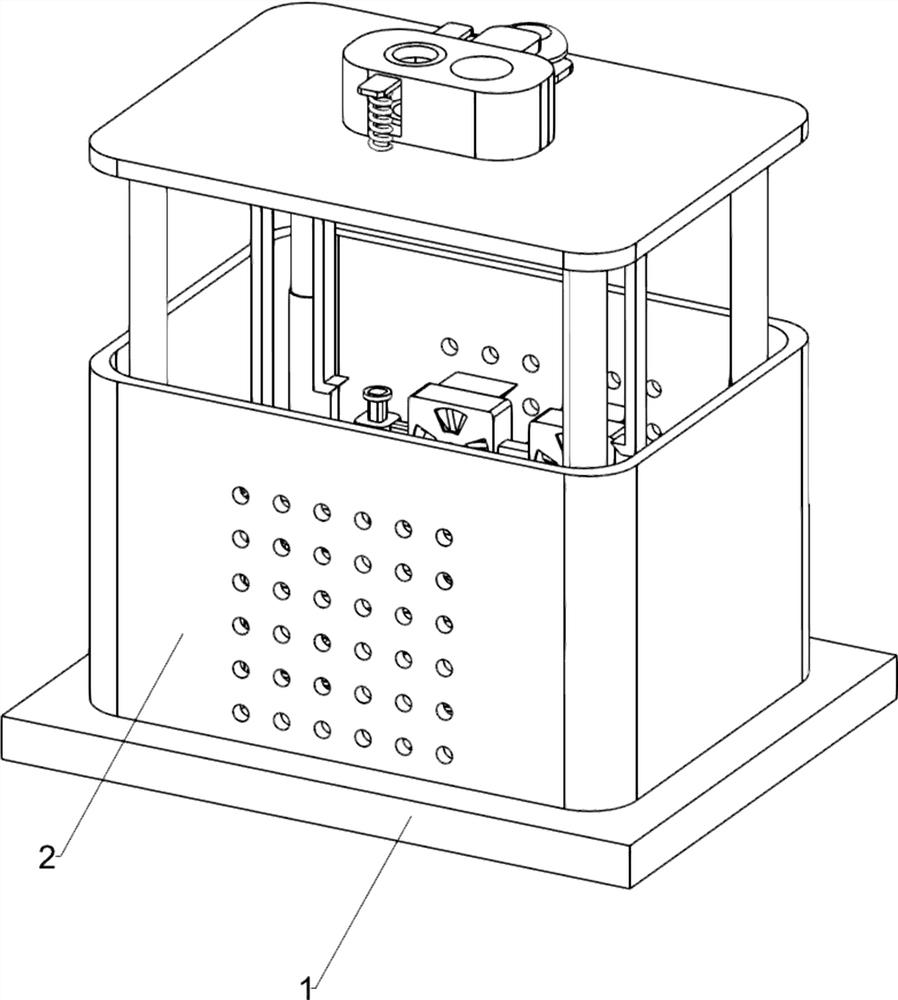

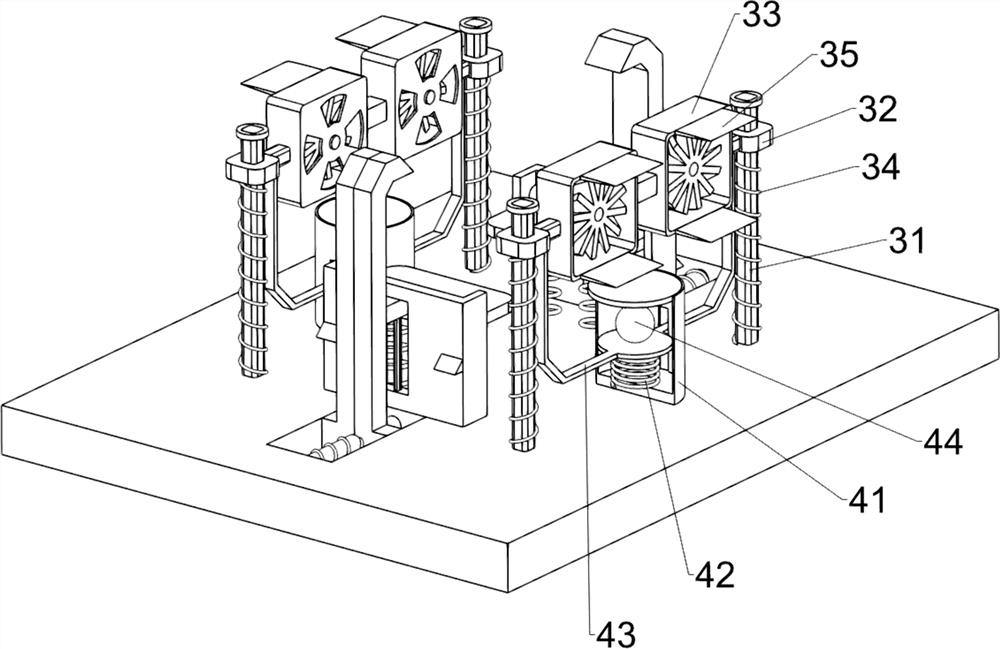

[0028] A lithium battery cooling device, such as Figure 1-3 As shown, it includes a fixed plate 1, a heat dissipation frame 2, a heat dissipation mechanism 3 and a gravity lifting mechanism 4. The upper side of the fixed plate 1 is provided with a heat dissipation frame 2, and the fixed plate 1 is provided with a heat dissipation mechanism 3. The heat dissipation mechanism 3 and the heat dissipation frame 2, the cooling mechanism 3 is provided with a gravity lifting mechanism 4.

[0029] When the device needs to be used, the device is installed on the car, the lithium battery is placed in the heat dissipation frame 2, and then the heat dissipation mechanism 3 is started, and the heat dissipation mechanism 3 will dissipate heat to the lithium battery, and the car will vibrate when moving. Then the gravity lifting mechanism 4 is operated, and then the heat dissipation mechanism 3 is moved, so that the heat dissipation mechanism 3 can better dissipate heat for the lithium batter...

Embodiment 2

[0035] On the basis of Example 1, such as figure 2 , Figure 4 , Figure 5 , Image 6 with Figure 7 As shown, a damping mechanism 5 is also included, and the damping mechanism 5 includes a guide plate 51, a block 52, a first pressing plate 53 and a third spring 54, and the upper left and right sides of the fixed plate 1 are provided with guide plates 51, Blocks 52 are provided on the front and rear sides of the guide plate 51 , and a first pressure plate 53 is slidably provided on the guide plate 51 . Two third springs 54 are connected between the first pressure plate 53 and the fixed plate 1 .

[0036] When the device needs to be used, the device is installed on the car, and the lithium battery is placed between the first pressure plates 53, and then when the car is moving, the shock of the lithium battery will be damped by the buffer force of the third spring 54, so that the lithium battery Batteries are not easily damaged.

[0037] Also includes clamping mechanism 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com