Sulfur hexafluoride gas warehouse management system and method based on distributed Internet of Things

A technology of sulfur hexafluoride gas and warehouse management system, applied in logistics, data processing applications, instruments, etc., can solve the problems of complex warehouse management, error-prone efficiency, etc., so as to improve efficiency, reduce the complexity of warehouse management and reduce labor costs. The effect of operating error rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In the following description, specific details such as specific system structures and technologies are presented for the purpose of illustration rather than limitation, so as to thoroughly understand the embodiments of the present invention. It will be apparent, however, to one skilled in the art that the invention may be practiced in other embodiments without these specific details. In other instances, detailed descriptions of well-known systems, devices, circuits, and methods are omitted so as not to obscure the description of the present invention with unnecessary detail.

[0047] In order to illustrate the technical solutions described in the present invention, specific examples are used below to illustrate.

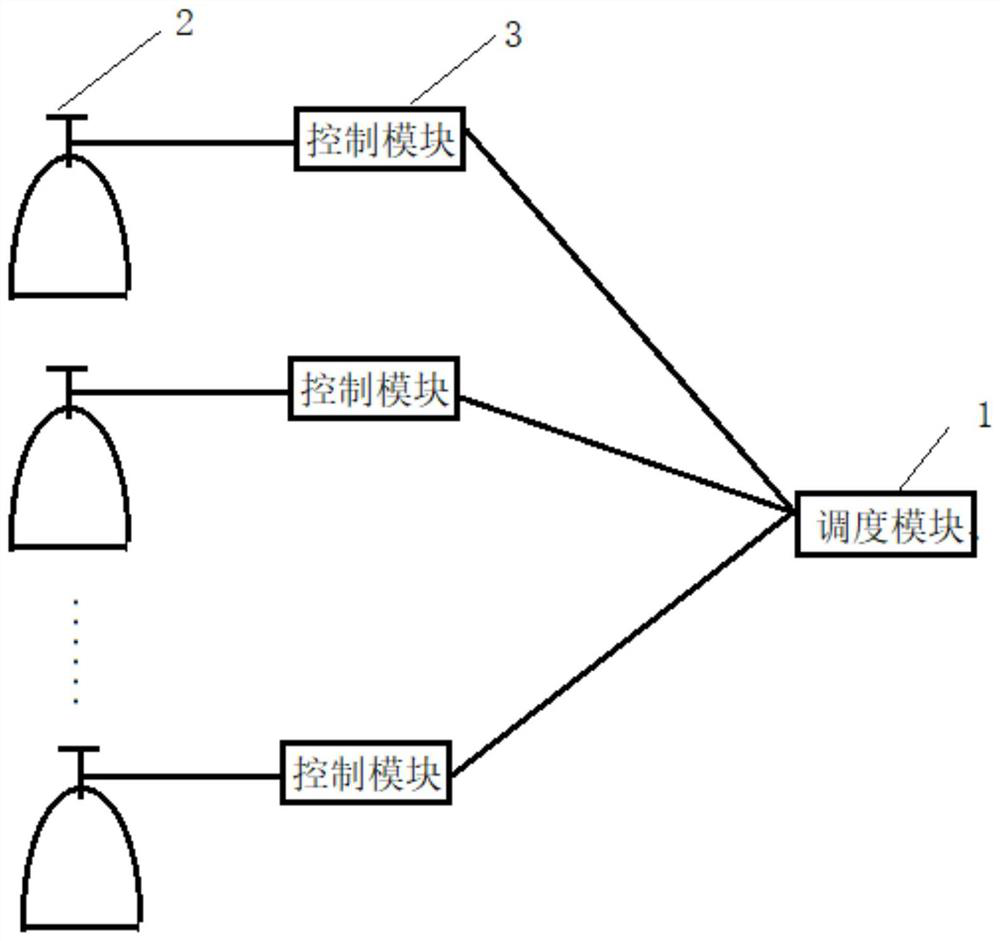

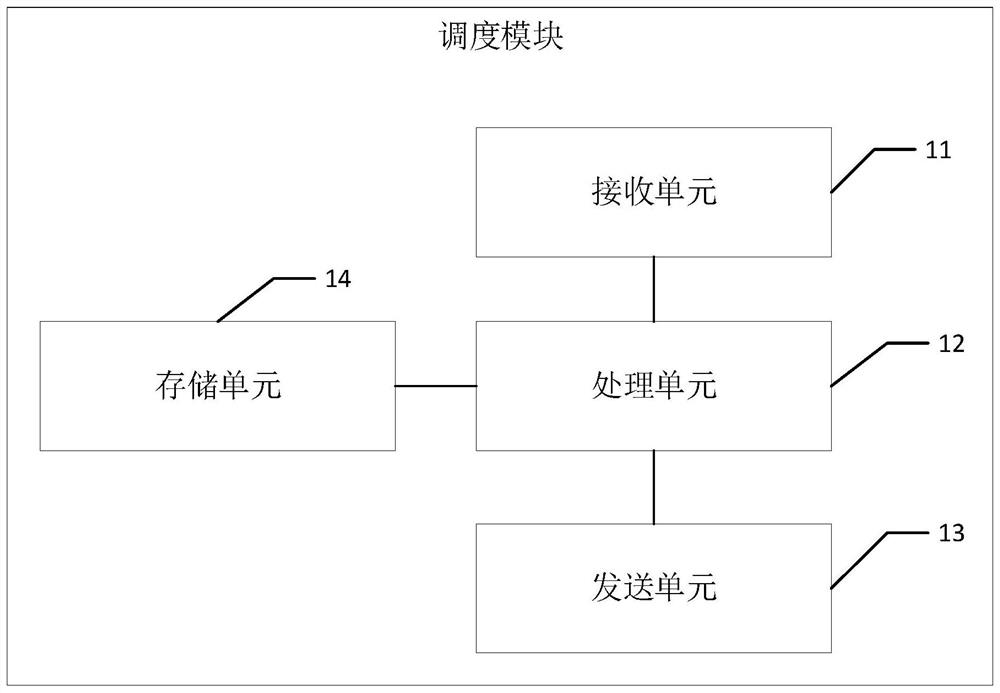

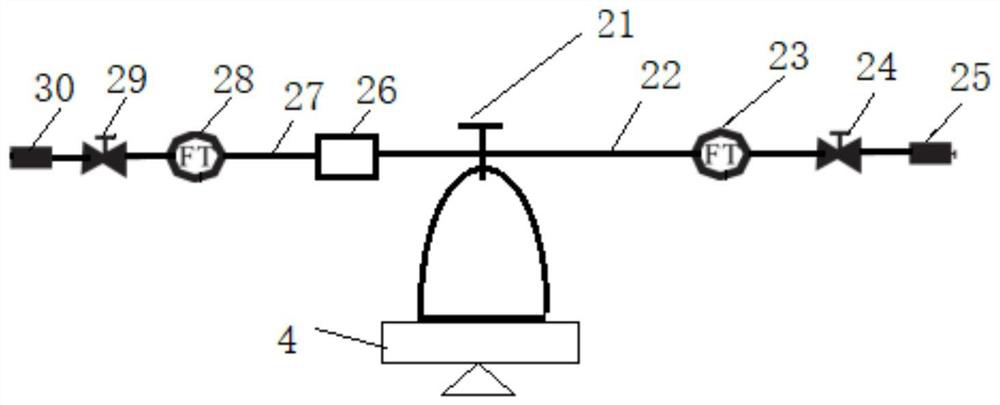

[0048] figure 1 A schematic diagram of a sulfur hexafluoride gas storage management system based on the distributed Internet of Things provided for an embodiment of the present invention may include: a scheduling module 1, a plurality of sulfur hexafluoride gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com