Isobaric combustion device for quenching test

A technology of isobaric combustion and quenching, which is applied in the direction of chemical analysis using combustion, can solve the problem of inability to accurately reflect the relationship between combustion pressure and the critical scale function of quenching, and achieve excellent test efficiency, improved accuracy, and high test efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

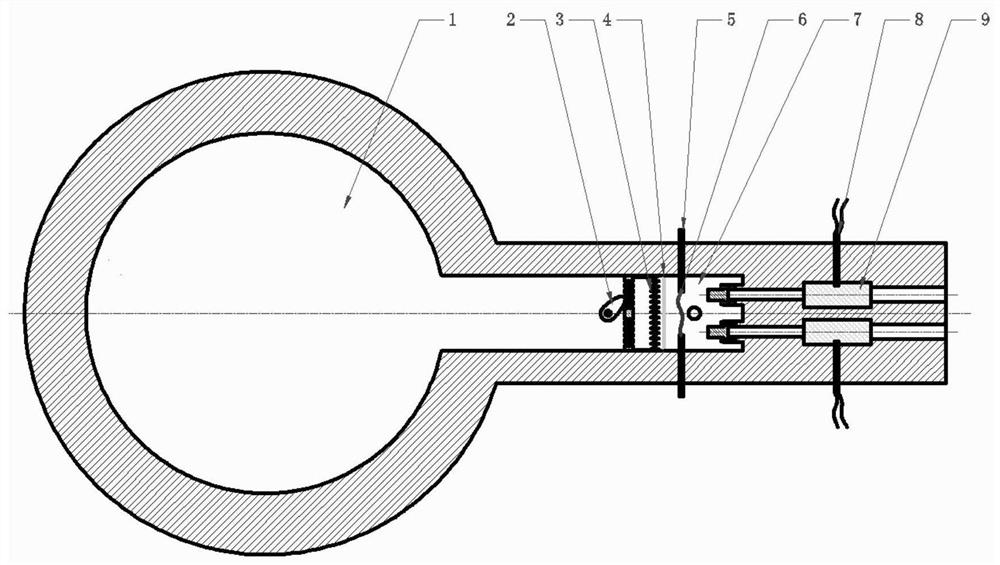

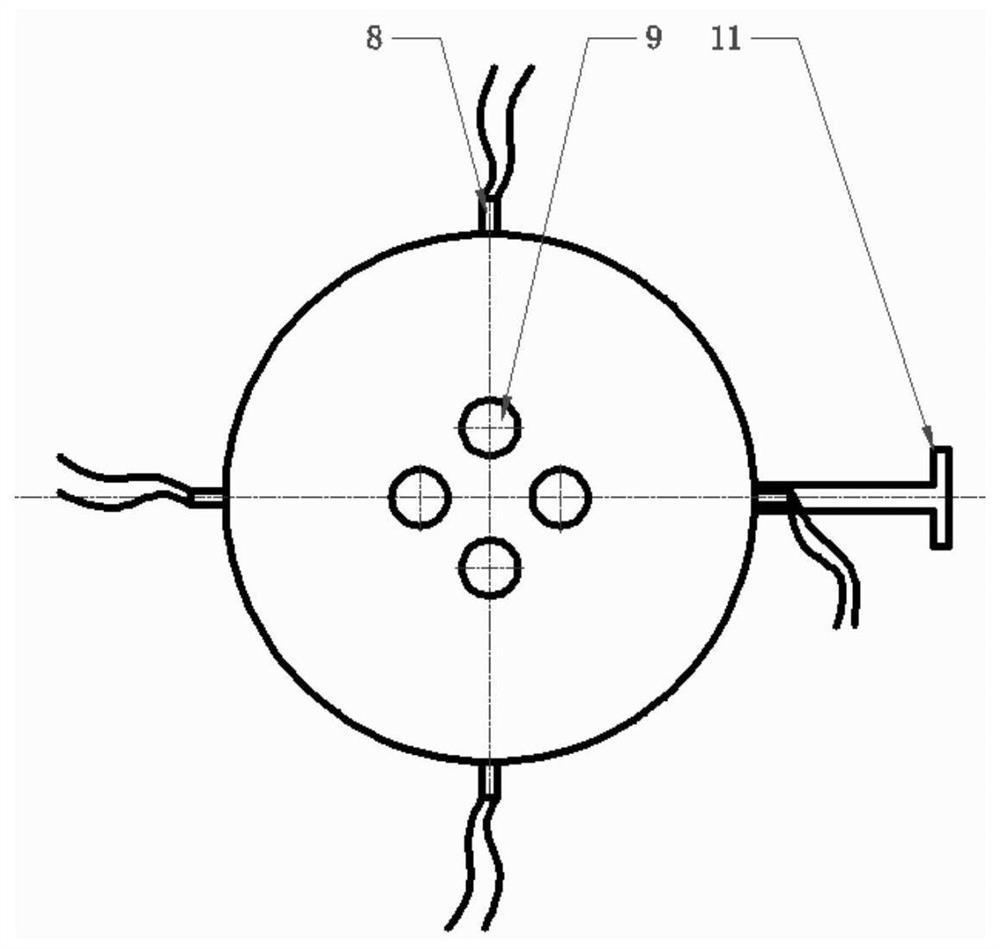

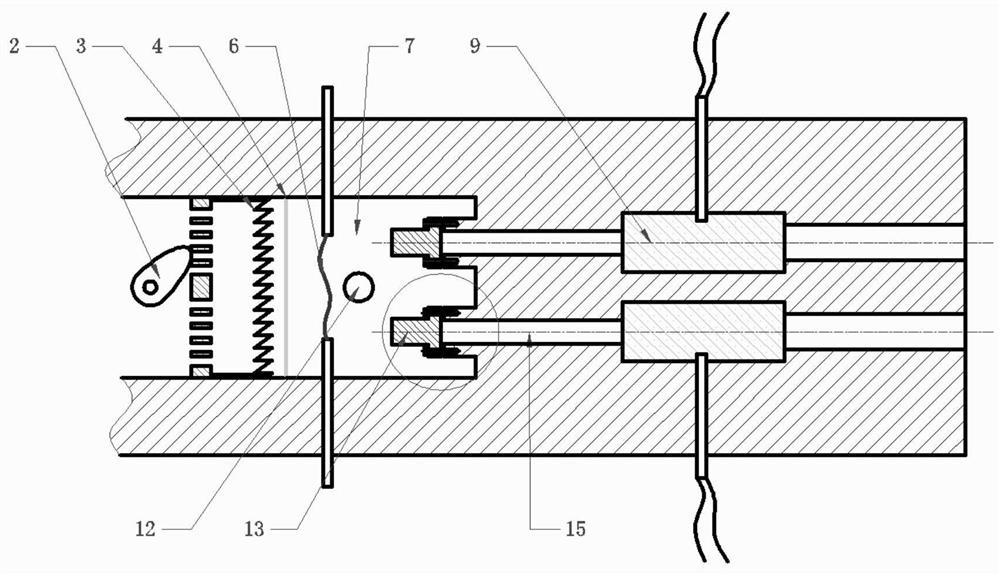

[0024] The present invention is described in conjunction with accompanying drawing.

[0025] Such as Figure 1~4 As shown, an isobaric combustion device for quenching test, including a housing, a pressure stabilizing chamber 1, a cam 2, a film cutter 3, a diaphragm 4, an electric explosive wire pin 5, an electric explosive wire 6, a main Combustion chamber 7, thermocouple 8, optical glass window 9, metal foil gasket 10, rotating shaft 11, air inlet 12, pressure cap 13, bolt 14, auxiliary combustion chamber 15;

[0026] The end of the housing is evenly distributed with several auxiliary combustion chambers 15 along the circumferential direction. Hole 12, the main combustion chamber 7 communicates with each auxiliary combustion chamber 15, the quenching passage is between the main combustion chamber 7 and the auxiliary combustion chamber 15; the main combustion chamber 7 and the pressure stabilizing chamber 1 are separated by a polyester diaphragm 4; The main combustion chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com