Micro-magnetic nondestructive testing sensors suitable for concave curved surface

A non-destructive testing and sensor technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of difficult detection of micro-magnetic sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

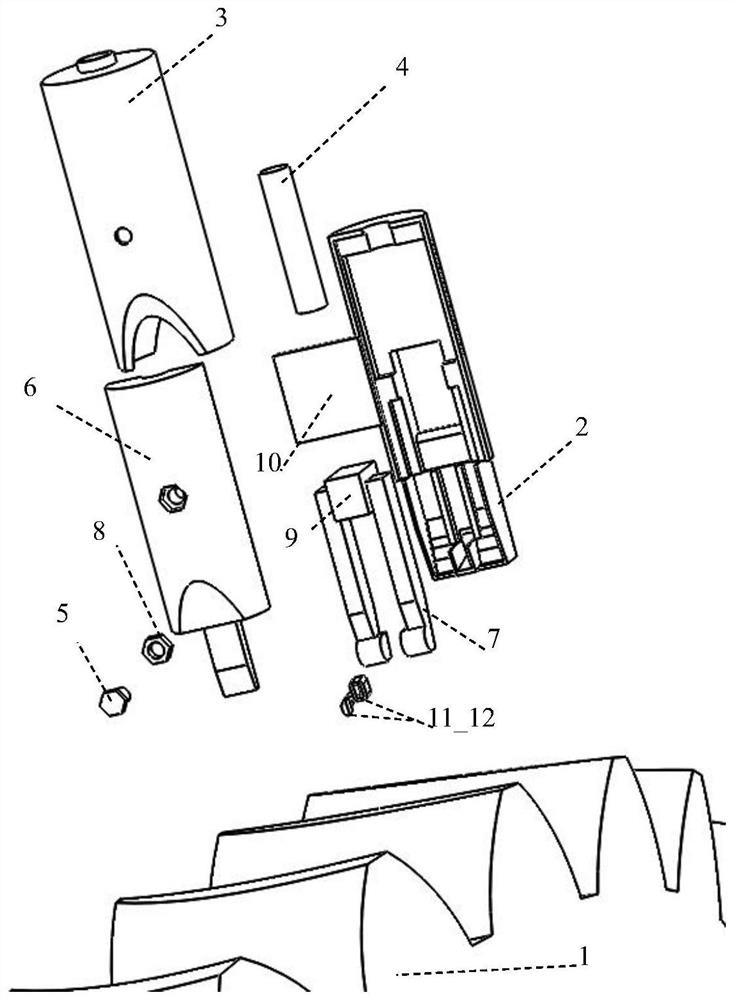

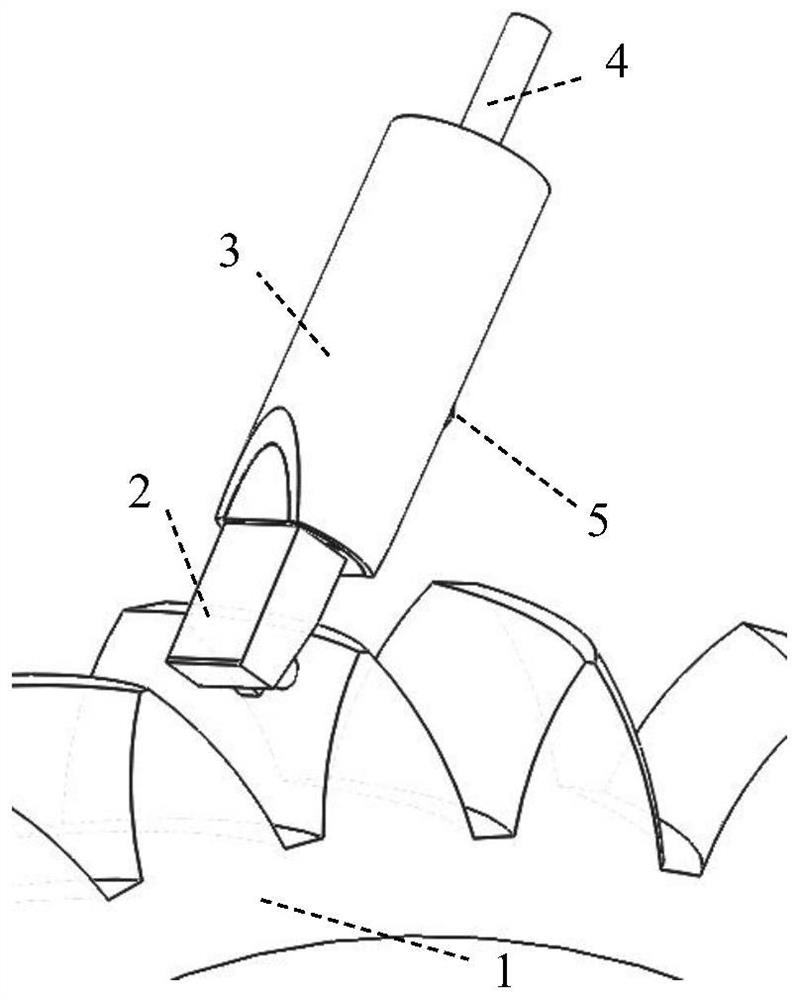

[0016] According to the above invention content, the spur gear tooth profile surface micro-magnetic non-destructive testing sensor can provide the following implementation methods.

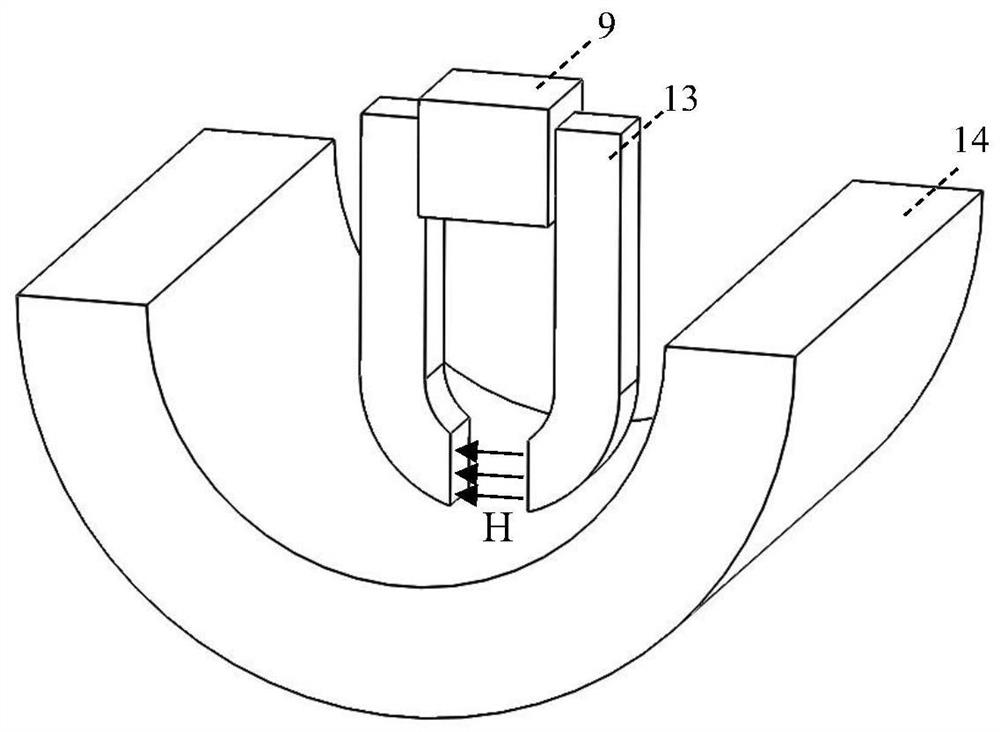

[0017] According to the shape of the spur gear tooth profile and the detection space of the test piece, the excitation part of the yoke and the placement position of the detection element are improved. The sensor can extract the magnetic signal from the concave curved test piece by means of U-shaped yoke side inclined plane excitation, and the design of the local boss and the horn-shaped yoke can make the sensor fit better with the test piece.

[0018] The present invention will be further described below in conjunction with the accompanying drawings and the following embodiments, and the specific implementation examples provided below are only descriptive, not restrictive, and cannot be used to limit the protection scope of the present invention.

[0019] figure 1 For the schematic diagram of se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com