Printing ink viscosity on-line measuring device and method

A technology for measuring device and ink viscosity, applied in the direction of measuring device, flow characteristics, instruments, etc., can solve the problems of inaccurate measurement results, no patents and open literature reports, etc., and achieve simple mechanical structure, improved measurement accuracy, and viscosity. The effect of accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

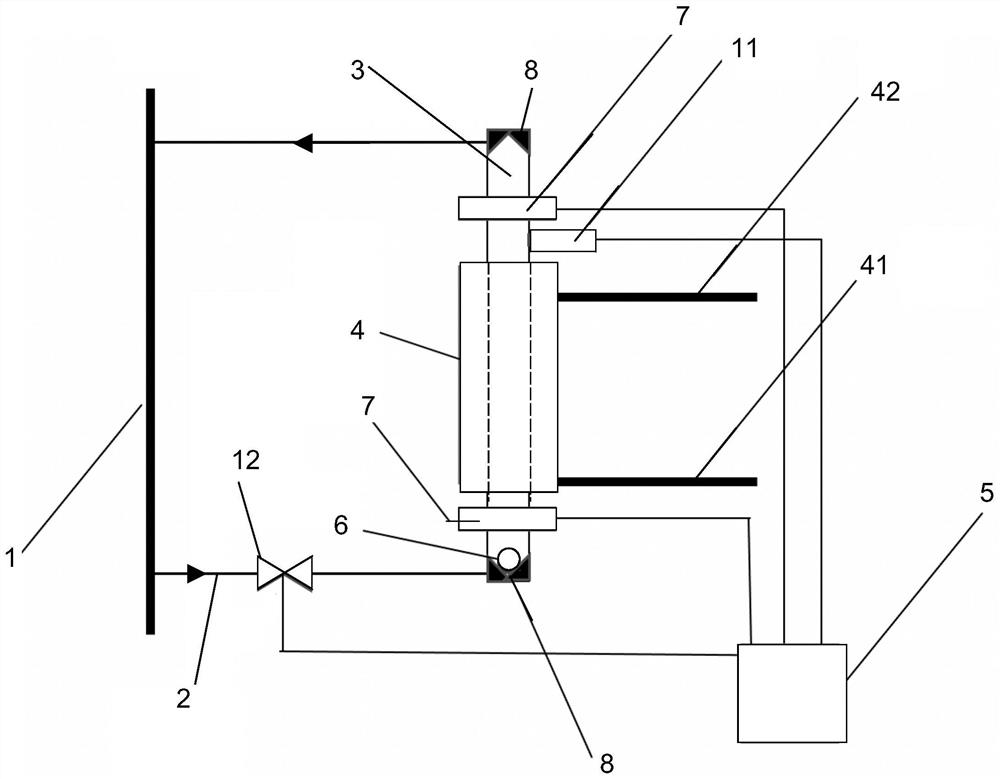

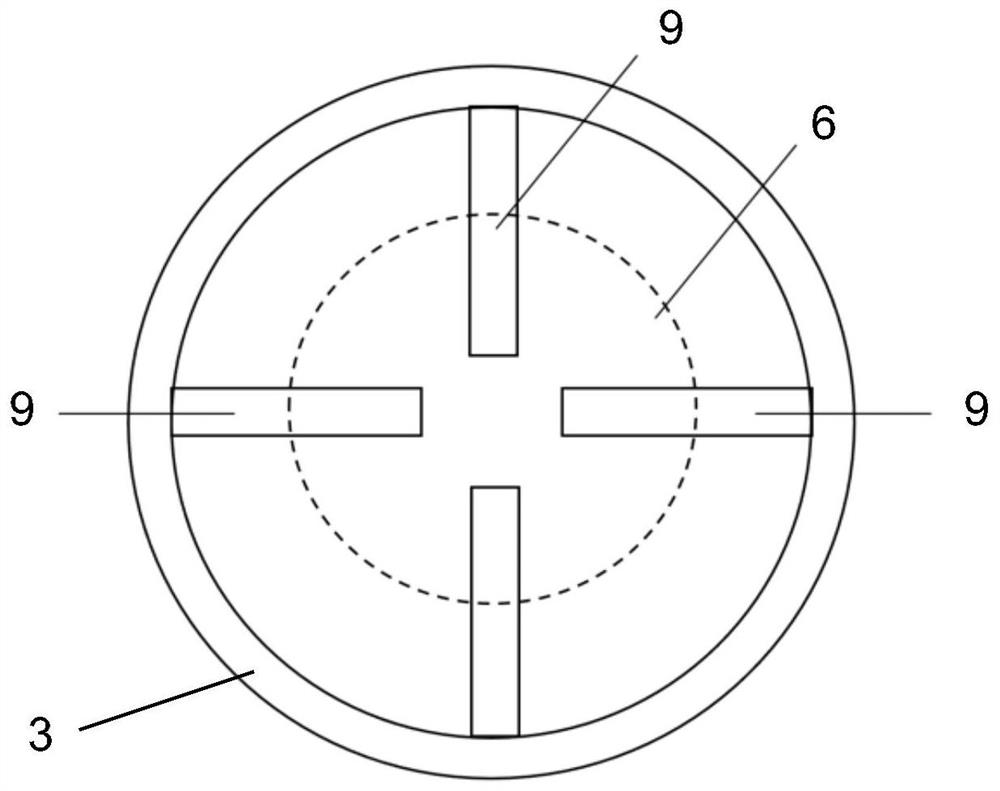

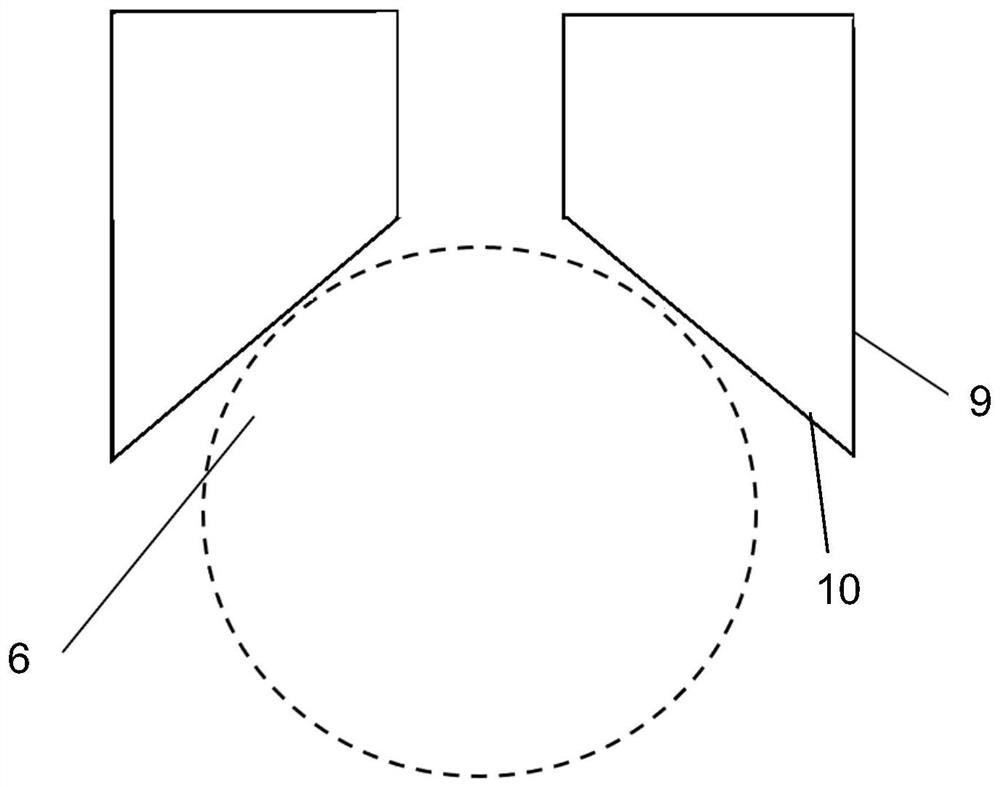

[0054] Ink viscosity online measuring device of the present invention such as figure 1 As shown, the same as the prior art, it also includes the main ink delivery pipeline 1. The difference is that it also includes a measurement branch 2 branched from the ink delivery main pipeline 1, which is vertically arranged and the bottom is connected to the measurement branch. The branch 2 is connected with the viscosity measuring tube 3, the heat exchange device 4 outside the viscosity measuring tube 3, and the host computer 5. The measuring branch 2 is provided with a valve 12 to control whether the measuring branch 2 is opened or not. , high-frequency switch can realize continuous measurement of the ink viscosity through the viscosity measuring tube 3; the viscosity measuring tube 3 is provided with a measuring ball 6, and the top of the viscosity measuring tube 3 is connected back to the ink delivery main pipeline 1 through the pipeline. When the valve 12 is opened, the ink enters t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com