A range hood, a working method of a range hood and a kitchen appliance

A technology for range hoods and working methods, which is applied in the direction of oil fume removal, heating methods, household stoves/stoves, etc., and can solve problems such as affecting the effect of range hoods on the range hood, the overall structure of the range hood is large, and the effect of range hoods is different. To achieve rich functions, improve the effect of oil suction, and enhance the user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

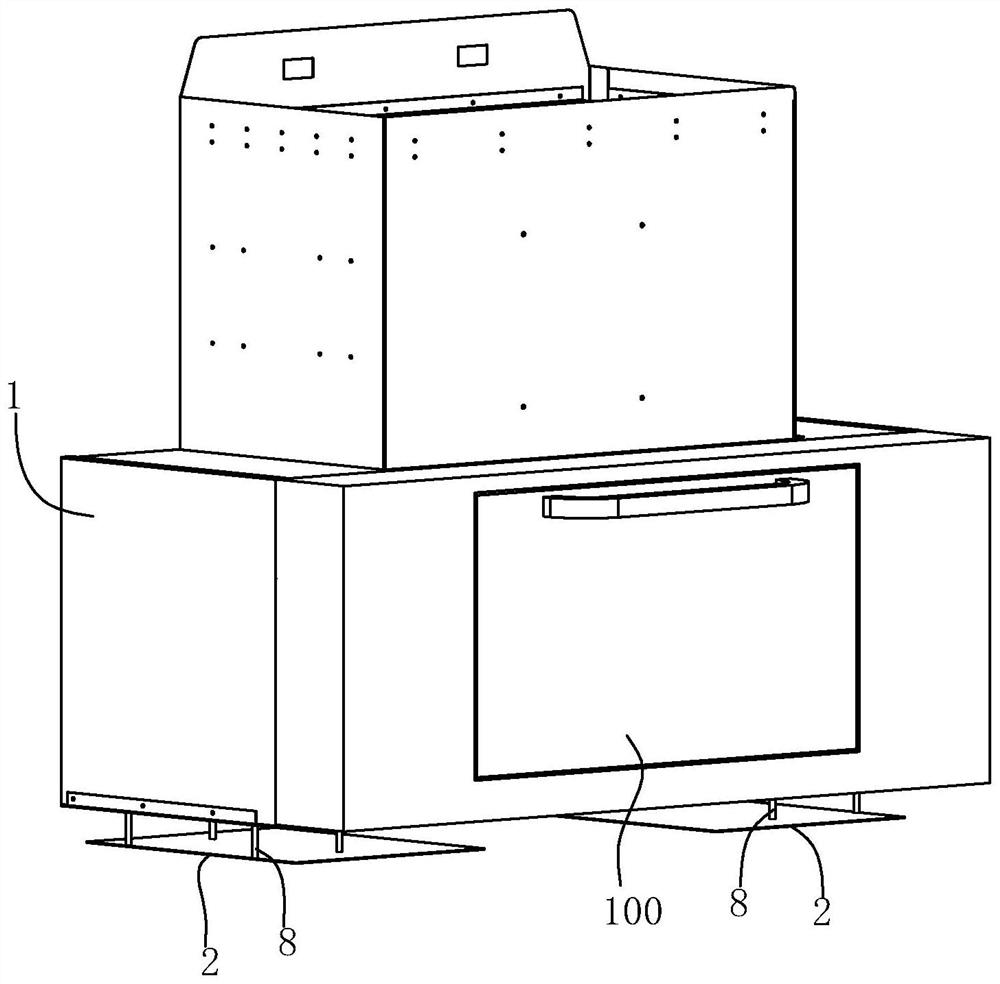

[0039] Such as Figure 1 to Figure 6 As shown, the range hood in this embodiment includes a casing 1, a first plate body 2, a second plate body 3, a fan 4 and a driving mechanism.

[0040] The casing 1 is provided with at least two oil fume passages 11, and the number of the oil fume passages 11 matches the number of cooking areas on the cooker. Specifically, one oil fume channel 11 is provided corresponding to each cooking area on the cooker, and each cooking area forms an oil smoke generating area, and the corresponding oil fume channel 11 is responsible for the suction work of the oil smoke generated in the oil smoke generating area. For example, there are usually two cooking areas on the cooker, thereby forming two oil fume generating areas, correspondingly, the number of oil fume passages 11 can be set to two.

[0041] The fume passage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com