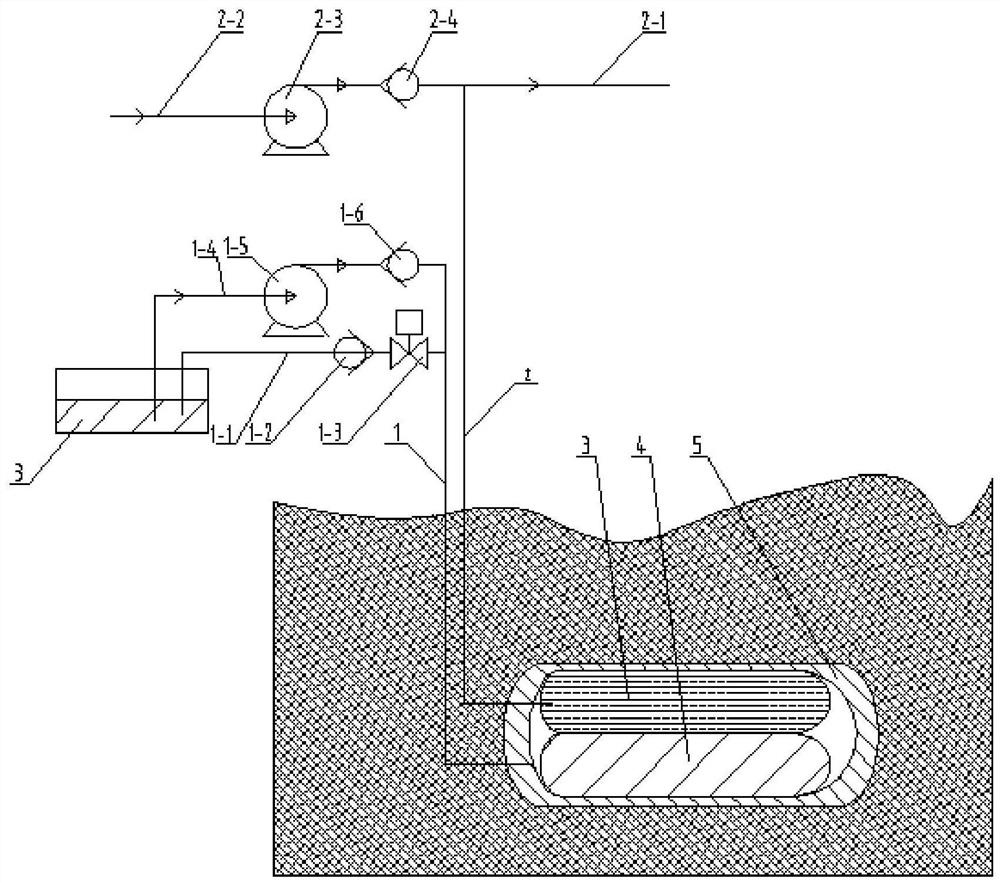

Underground oil depot based on composite material bag body

An underground oil depot and composite material technology, which is applied in the field of underground oil depots based on composite material capsules, can solve problems such as installation or groundwater level influence, complex construction, etc., and achieve the effects of shortening construction time, long service life and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1, the pressure supplement medium is the water in the reservoir;

[0031]The underground oil depot is located in the reservoir. When the oil is imported, the oil pump on the oil input pipe is turned on, and the oil is filled into the flexible oil storage bag continuously and at constant pressure through the oil input pipe. At the same time, the oil inlet check valve prevents the oil from flowing back. The inner wall of the outer protective bag is under constant pressure. As the volume of the flexible oil storage bag continues to increase and the flexible liquid storage bag is squeezed, the stop valve on the liquid outlet line is opened, and the pressure replenishing medium in the flexible liquid storage bag is released along the liquid outlet line. Squeeze out and discharge into the liquid storage tank, the liquid outlet check valve prevents the discharged water from flowing back into the reservoir, or the liquid discharge check valve prevents the discharged s...

Embodiment 2

[0033] Embodiment 2, based on the first embodiment, the pressure supplement medium can also be seawater in the sea;

[0034] When the oil is input, the oil delivery pump on the oil input pipe is turned on, and the oil is filled into the flexible oil storage bag continuously and at constant pressure through the oil input pipe, and at the same time, the oil inlet check valve prevents the oil from flowing backward. The inner wall of the outer protective bag is under constant pressure. As the volume of the flexible oil storage bag continues to increase and the flexible liquid storage bag is squeezed, the stop valve on the liquid outlet line is opened, and the pressure replenishing medium in the flexible liquid storage bag is released along the liquid outlet line. Squeeze out and discharge into the liquid storage, and the liquid discharge check valve prevents the discharged seawater from flowing back into the sea; the oil product input is completed.

[0035] When the oil product is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com