Beam-wall quick-mounting and early-dismounting beam structure facilitating beam bottom adjustment and positioning

A technology for adjusting positioning and beam structure, applied in the treatment of formwork, building construction, and on-site preparation of building components, etc., can solve problems such as affecting concrete quality, uncontrollable and unadjustable supporting force, positioning adjustment, etc., to ensure Beam quality and construction safety, avoid slurry leakage and beam structure deviation, and achieve the effect of installation position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

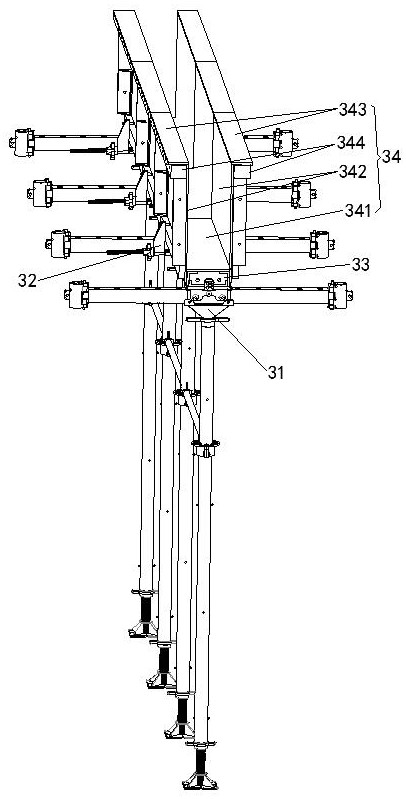

[0058] A beam-wall quick-installation and early-demolition beam structure that facilitates the adjustment and positioning of the beam bottom in this embodiment, such as figure 1 As shown, it includes a beam support assembly 31, a beam bottom keel end fixed connector 33, and a beam structure formwork assembly 34. The top of the beam support assembly 31 is fastened with a beam bottom keel end fixed connector 33, and the beam structure template The assembly 34 includes a beam bottom plate 341, a beam side plate 342 symmetrically arranged on both sides of the beam bottom plate 341, a beam wall inner corner floor formwork 343 arranged on the top of the beam side plate 342, and the bottoms of the beam side plates 342 on both sides extend to the beam bottom plate The lower side of the bottom end surface of 341 and the bottom end surface of the beam bottom plate 341 form a beam bottom groove that is engaged with the fixed connector 33 at the bottom of the beam keel; the tops of the bea...

Embodiment 2

[0062] This embodiment is further optimized on the basis of embodiment 1, such as figure 1 As shown, it also includes the supporting connecting keel 344 of the formwork of the inner corner of the beam wall. And the edge of the beam wall inner corner floor formwork 343 away from the beam side plate 342 extends to the outside of the edge of the beam wall inner corner floor formwork support connecting keel 344 to form a common side structure.

[0063] The formwork support connecting keel 344 of the inner corner of the beam wall is a rectangular beam structure or a U-shaped beam structure. The wall corner floor formwork 343 is supported and reinforced; the left side or the right side of the beam wall corner floor formwork support connection keel 344 corresponds to the left side of the beam side plate 342 on the left side or the beam side plate 342 on the right side The right side is arranged in close contact, and is used to support and reinforce the beam side plate 342, so as to ...

Embodiment 3

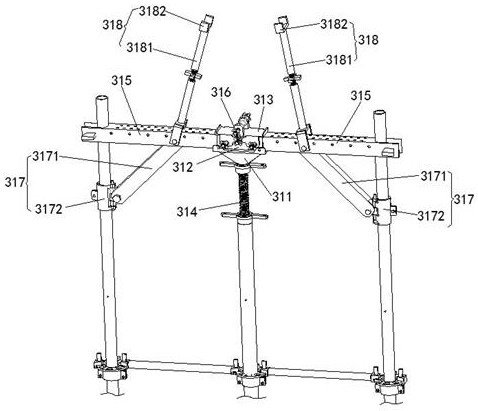

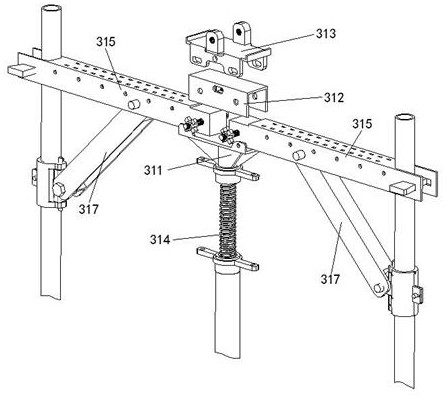

[0067] This embodiment is further optimized on the basis of embodiment 1 or 2, such as figure 2 As shown, the beam support assembly 31 includes a beam support main keel 315, a beam structure lifting support screw assembly 314, a beam structure support tray 311 arranged on the top of the beam structure lift support screw assembly 314, a beam structure support tray 311 arranged on the beam structure support tray 311 The top beam structure supports and connects the jacking bracket 312, and the beam structure positioning adjustment supporting jacking bracket 313 arranged on the top of the beam structure supporting and connecting the jacking bracket 312, the top of the beam structure lifting and supporting screw assembly 314 penetrates the beam structure supporting tray 311 upwards And it is connected with the bottom of the beam structure support connection top bracket 312, the left and right symmetrical engagement between the beam structure support connection top bracket 312 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com