Multistage instant back-mixing aerobic composting reaction device and working method thereof

A reaction device, a technology for aerobic composting, applied in the field of aerobic composting reaction devices, can solve the problems of unavoidable nitrite accumulation and nitrous oxide, inability to solve connection problems, high maintenance costs and high costs, and avoid space for composting facilities. problems, avoid secondary pollution, and reduce ammonia production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

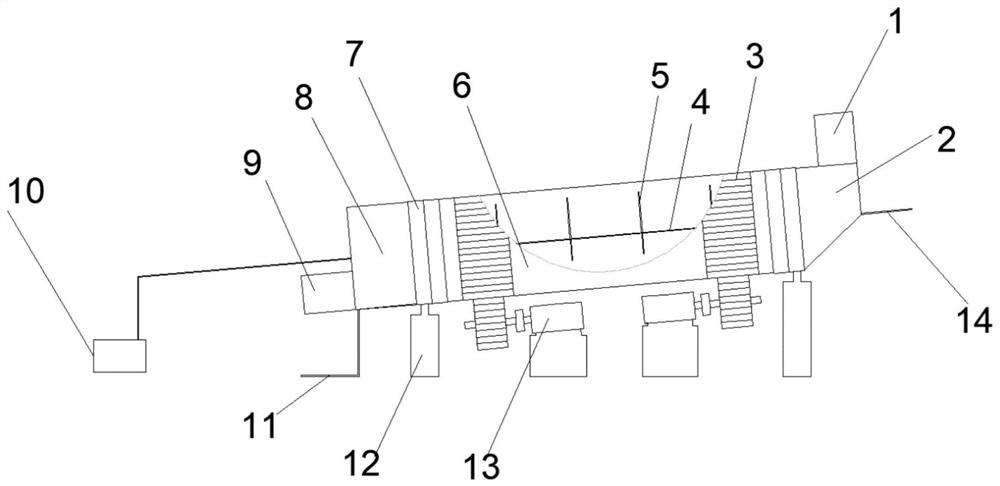

[0041] A kind of aerobic composting reaction device of multi-stage instant back-mixing, such as Figure 1~2 As shown, including the cylindrical body, the cylindrical body maintains an inclination angle of 3-5° with the horizontal plane, the upper part of the cylindrical body is the feeding area 2, the middle part is the rotating cylinder 6, and the lower part is the discharging area 8. The material area 2 is higher than the discharge area 8, which can make the compost material move towards the discharge port under the action of gravity;

[0042] The feed area 2 and the discharge area 8 are fixed areas, the upper end of the feed area 2 is the feed port 1, which is convenient for feeding materials, and the lower end of the discharge area 8 is the discharge port 9, which is convenient for discharging decomposed compost materials. There is a intercepting shaft 4 at the central axis, and the two ends of the intercepting shaft 4 are respectively fixed in the feeding area and the dis...

Embodiment 2

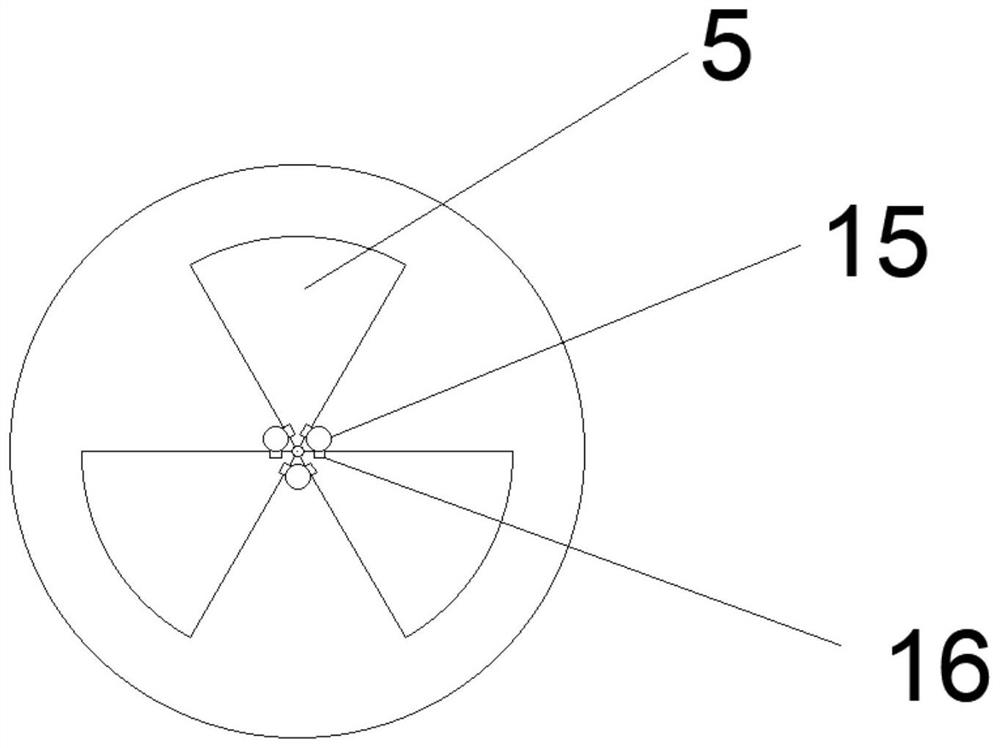

[0046] A multi-stage instant back-mixing aerobic composting reaction device, the structure is as shown in embodiment 1, the difference is that the retaining sheet 5 is provided with 3-5 groups, and each group of retaining sheet 5 is composed of three central angles of 60 ° The fan-shaped structure is composed of three fan-shaped structures evenly distributed in the same plane;

[0047] Both the retaining shaft 4 and the retaining sheet 5 are made of anti-corrosion materials, and stainless steel is used in this embodiment.

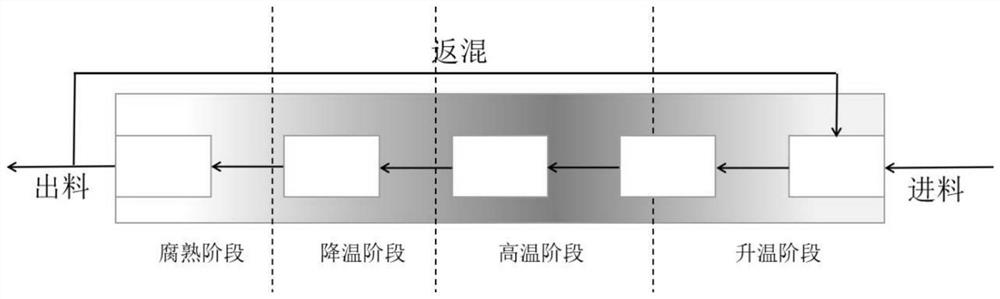

[0048] According to the research, it takes 10 days for the organic solid waste to decompose in the composting reactor, and 5-10 sets of interception sheets can be set up to retain the material in the next day or two days, so as to realize the organic matter decomposed in the previous step and the latter. section material mixing;

[0049] The retaining shaft 4 and the retaining sheet 5 are fixed throughout the system and do not rotate with the rotation of t...

Embodiment 3

[0051] A multi-stage instant back-mixing aerobic composting reaction device, the structure is as shown in embodiment 2, the difference is that the number of aeration hoses 15 is three, and the three aeration hoses are distributed and arranged at the bottom of each group of retaining sheets. In the gap between the adjacent fan-shaped structures, each aeration hose is provided with two ventilation ports 16 on both sides of the pipe wall near the retaining sheet, and each ventilation port is aligned with the fan-shaped structure, which can prevent the aeration hose from being The composting material is clogged, and the ventilation interface can blow off the materials stuck on the retaining sheet to prevent the material from staying on the retaining sheet for a long time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com