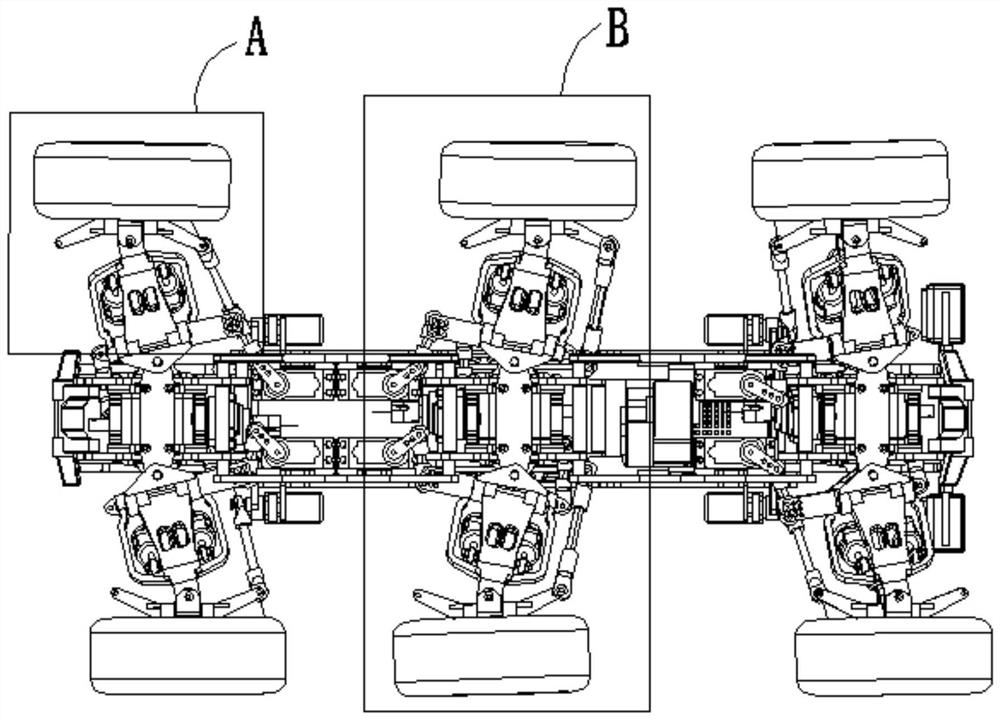

Wheel-foot type robot suspension mechanism, axle module and chassis

A suspension mechanism and robot technology, which can be used in motor vehicles, transportation and packaging, etc., can solve the problems of insufficient natural structural rigidity and inability to drive at high speed, and achieve the effect of strong off-road performance and maneuverability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

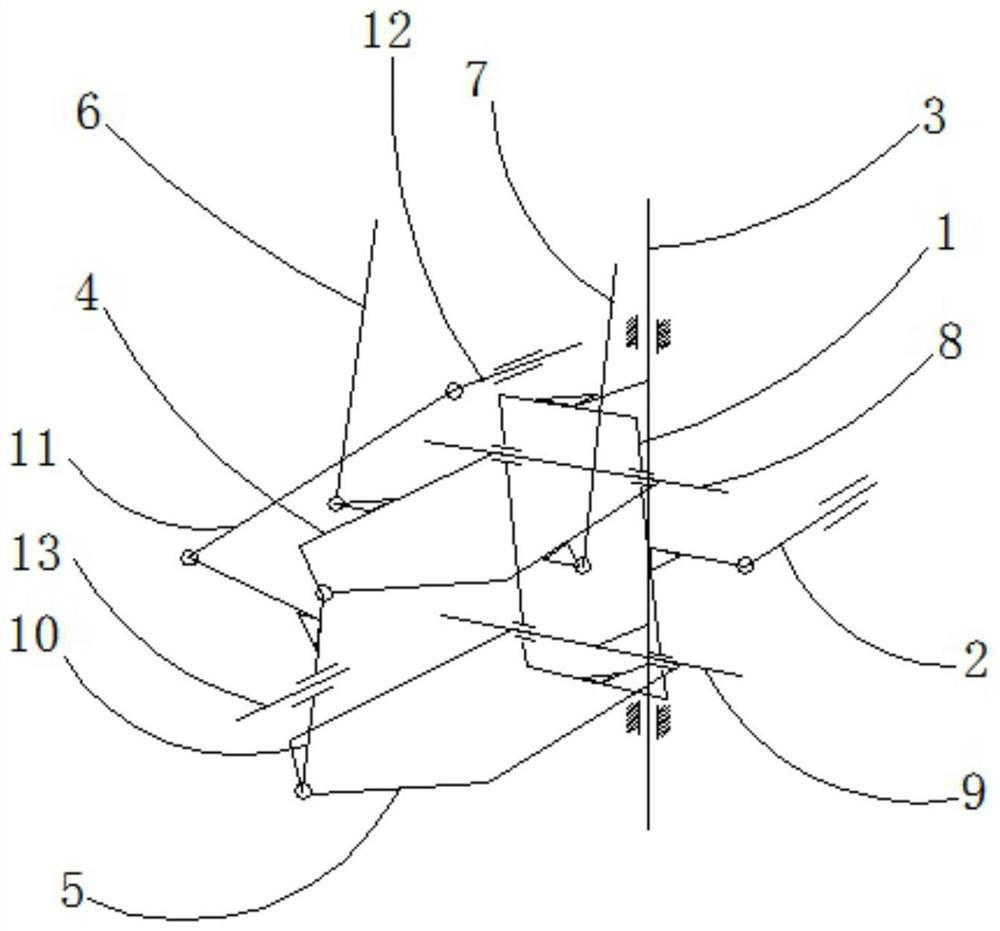

[0042] like figure 2 As shown, the embodiment of the present invention discloses a wheel-foot type robot suspension mechanism, which includes a front and rear swing part, an up and down movement part and a steering part;

[0043] The front and rear swing parts are movably installed on the main body of the robot chassis to swing back and forth;

[0044] The up and down movement part is movably installed on the front and rear swing parts for up and down movement; the up and down movement part extends out of the axle 13;

[0045] The steering part is hinged with the up and down moving part for steering movement.

[0046] In the present invention, the front and rear swinging part, the up and down moving part and the turning part are connected as a whole, which has the movement ability in three-dimensional space.

[0047] Specifically, the front and rear swing parts include a swing frame 1 and a first swing actuator 2; the swing frame 1 is installed on the robot chassis body thr...

Embodiment 2

[0060] like figure 2 As shown, the embodiment of the present invention discloses a wheel-foot type robot suspension mechanism, which includes a front and rear swing part, an up and down movement part and a steering part;

[0061] The front and rear swing parts are movably installed on the main body of the robot chassis to swing back and forth;

[0062] The up and down movement part is movably installed on the front and rear swing parts for up and down movement; the up and down movement part extends out of the axle 13;

[0063] The steering part is hinged with the up and down moving part for steering movement.

[0064] In the present invention, the front and rear swinging part, the up and down moving part and the turning part are connected as a whole, which has the movement ability in three-dimensional space.

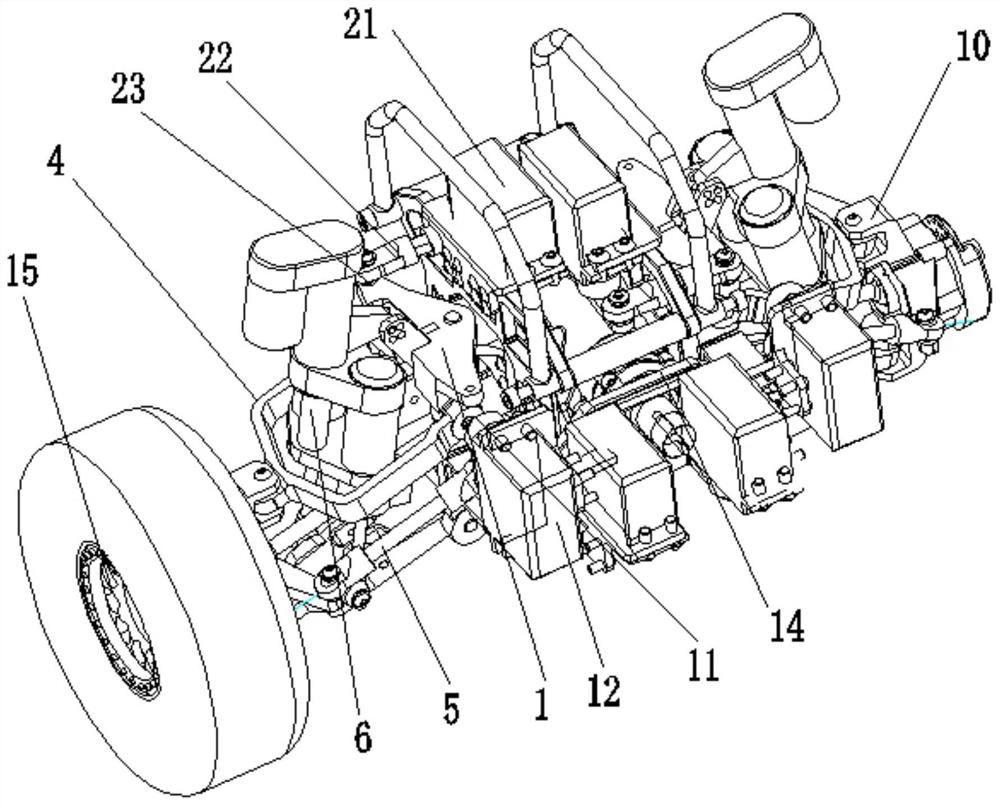

[0065] Specifically, such as Figure 5 As shown, the steering part includes a second steering knuckle 101, a second steering tie rod 102, a steering drive rod 103 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com