Orientation casting method for aluminum-nickel-cobalt integral magnetic steel

An aluminum-nickel-cobalt, integrated technology, applied in casting molding equipment, molds, mold components, etc., can solve the problems of excessive use of consumables and high costs, and achieve the effect of saving consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

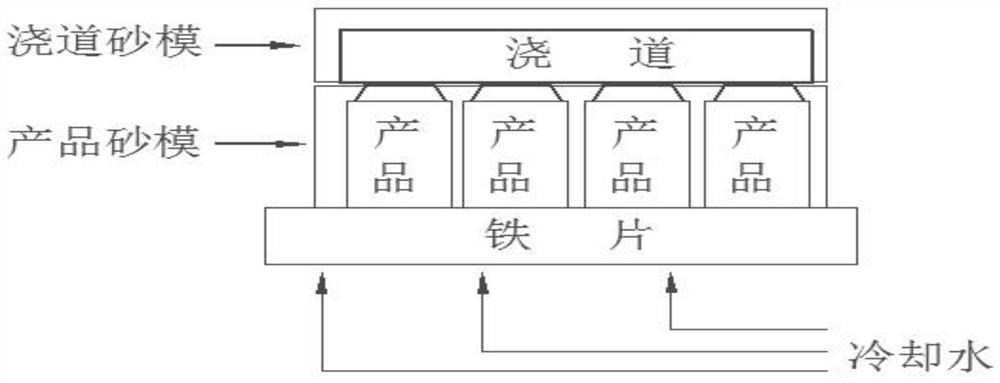

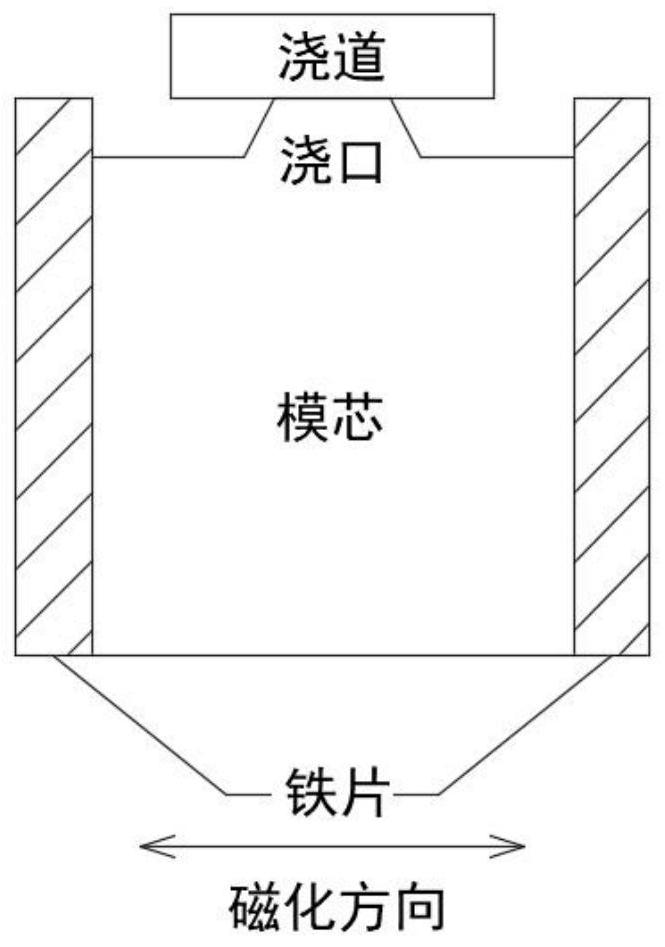

[0038] see figure 1 with figure 2 , the present invention provides a technical solution: AlNiCo monolithic magnetic steel orientation casting method, comprising the following steps:

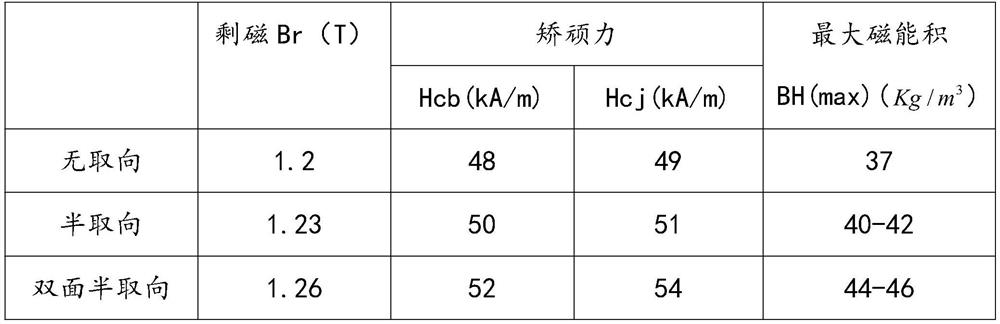

[0039] The double-sided semi-oriented pouring method adopted in the present invention, next, take the product casting method whose material grade is LNG37 as an example:

[0040] S1. Obtaining raw materials: select materials whose grades are LNG35 or LNG36 as raw materials;

[0041] S2. Design the mold, and design the mold corresponding to the sand mold used for product pouring according to the shape of the product;

[0042] S3. Sand mold molding for double-sided orientation casting method:

[0043] S31, pouring quartz sand into the mold and pressing it tightly;

[0044] S32. Along the direction of magnetization, iron sheets with a thickness of 8-12mm, a length and a width greater than the length and width of the mold core by 5-8mm are placed at both ends of each mold core in the mold;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com