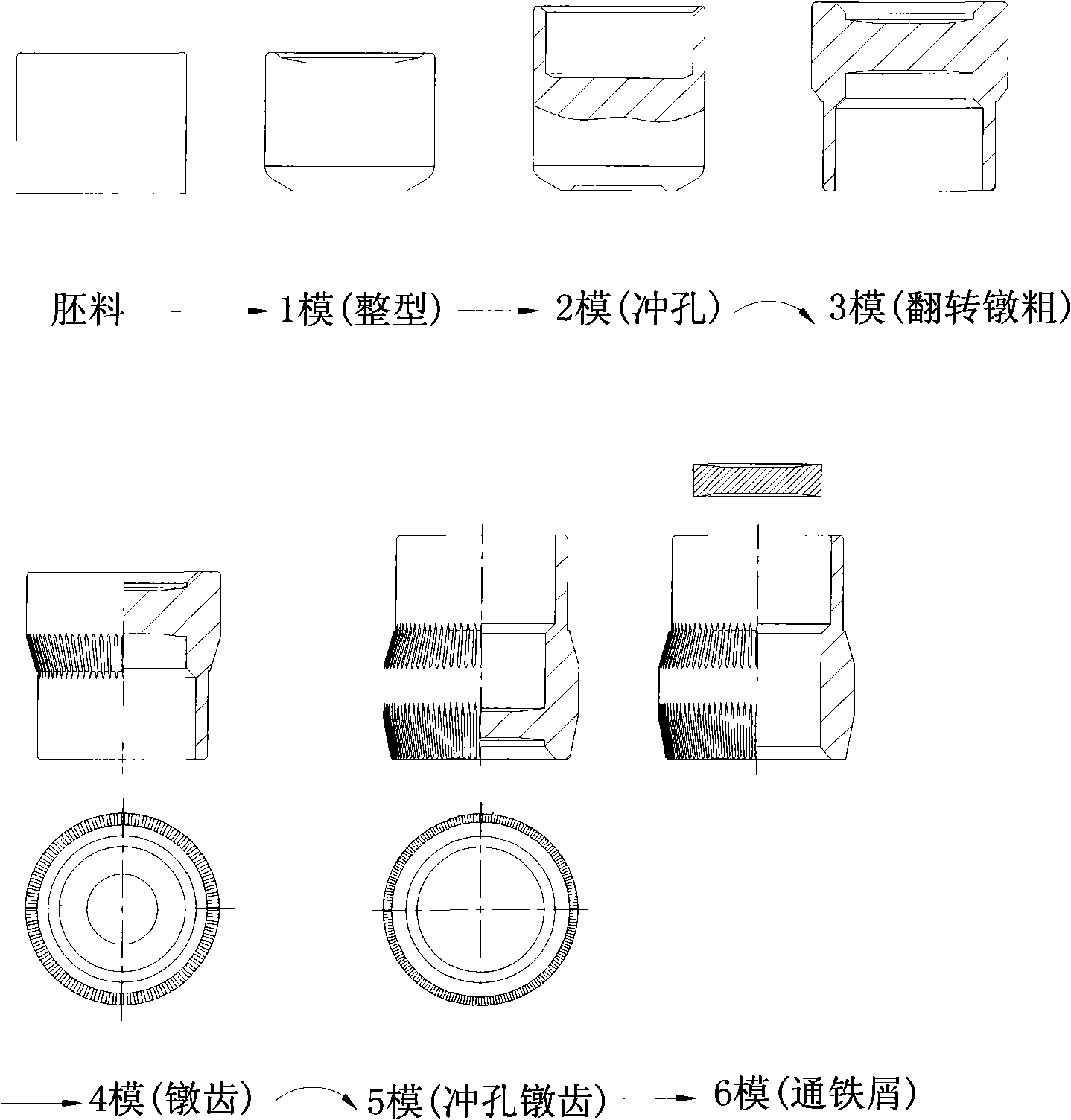

Multi-station cold-heading molding method of clutch conical blank

A molding method and multi-station technology, applied in metal processing equipment and other directions, can solve the problems of difficult processing, waste of raw materials, low production efficiency, etc., to achieve the effect of tight material organization, ensure product quality, and reduce the amount of consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] see figure 1 , a multi-station cold heading forming method for clutch conical blanks. The steel blanks are made into discs, which are respectively subjected to spheroidizing annealing, pickling, and wire drawing treatments, and are cut by an automatic cutting system to form a single clutch. The cone blank is formed into a clutch cone in a cold extrusion die, which specifically includes the following steps:

[0019] (1) Send the round finished material into the shearing mold through the feeding system, use the transverse shearing force of the scissors to cut, obtain a certain length of material, and use the clamp to send the cut material to the mouth of the first mold;

[0020] (2) Push the sheared material into the die by the punching tool. Since the head of the punching tool is in the shape of a processed raised step, the blank is flattened and placed on the front end by pressing the punching tool to apply pressure. Upsetting the inner chamfer positioning hole to form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com