Production process of high-nucleotide super-fresh soy sauce

A high nucleotide and production technology technology, applied in food science and other directions, can solve the problems that the umami taste of ingredients is not improved very much, no longer have umami taste, and increase the cost of preparation, so as to improve the quality and efficiency of koji making, The effect of improving profits and ensuring the quality of output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

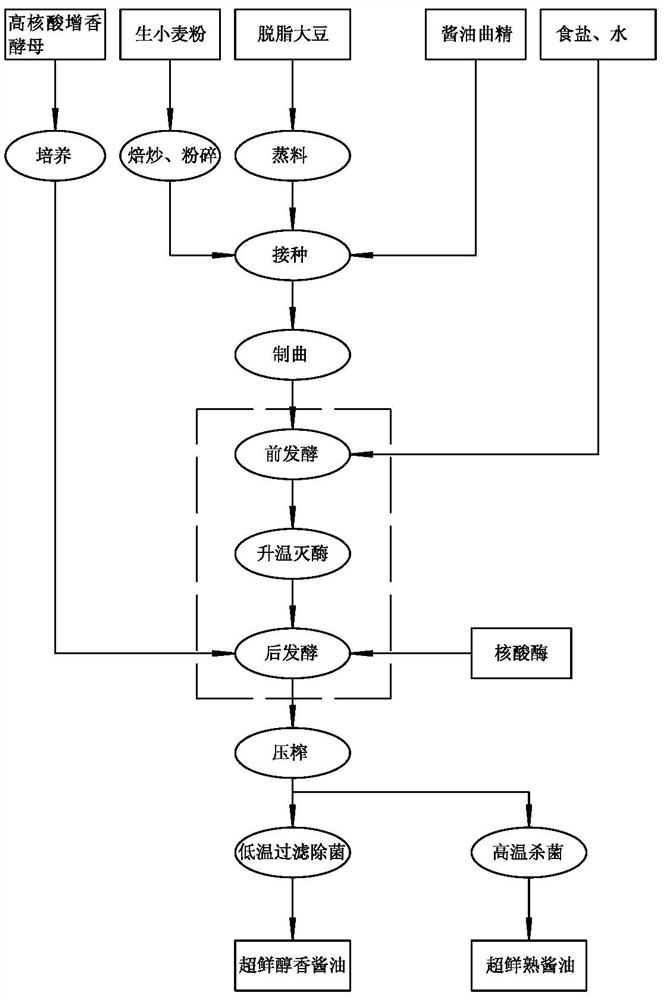

[0073] Such as figure 1 As shown, a high-nucleotide supernown soy sauce production process according to the present invention includes the following steps:

[0074] S1 preparation;

[0075] Prepare soybean meal and raw wheat at 55:45 according to the mass fraction;

[0076] S1.1 pulverizes the wheat baked and gets the fried wheat powder;

[0077] S1.2 steamer; put the soybean meal into the steamed ball, and the steam operation is carried out; S1.2 steamer includes the following steps:

[0078] Add water ratio: total raw material quantity: water = 1: 0.6-0.7, mixed curva moisture requirements 48% ± 2%;

[0079] S1.2.1 In the feed: After the soybean meal is entered the ball, the cover is sealed, and the ball is blocked;

[0080] S1.2.2 Dry: Open steam valve, dried 3 times, pressure 0-0.1-0.1-0- (0.12-0.16) -0 MPa, the last exhaust pressure is 0 MPa, turn off the exhaust valve;

[0081] S1.2.3 Water: Use Everwater, Into Water (Into the water forms a vacuum in the ball, faster and fas...

Embodiment 2

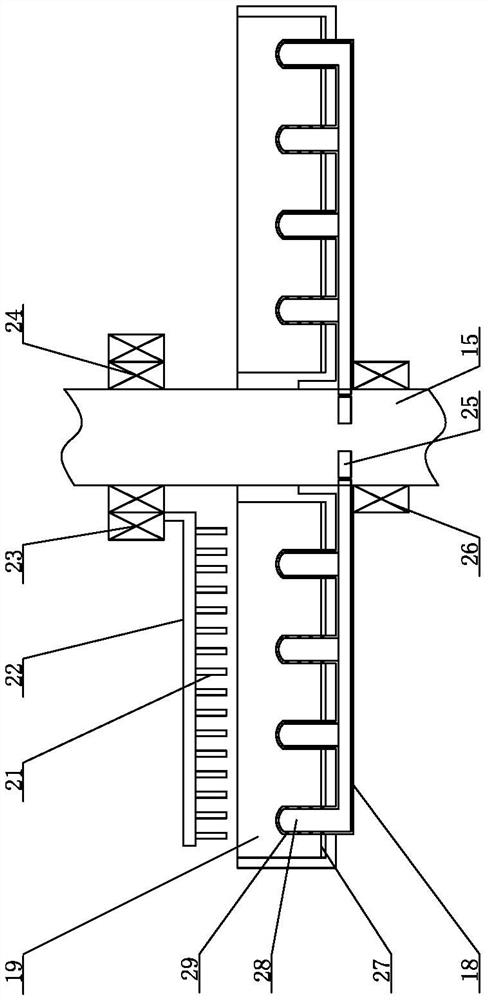

[0125] Such as Figure 2-5 As shown, the disc squeegee includes an outer trainer, a disc assembly, and a lifting feed device, a disc assembly, and a lifting feed apparatus, which are mounted in the outer position, the outer circle body 8, and the inner wall of the outer circle. The temperature sensor and humidity sensor are installed; the sealing warehouse capable of opening and closing is provided on the outer casing body, and one or more windows are opened on the side wall of the outer circle body, and the ventilation flow valve is mounted on the ventilation window.

[0126] The disc assembly includes an upper bearing mounting seat and a lower bearing mounting seat, and the upper bearing mounting seat and the lower bearing mounting seat are fixed on the upper and lower bottom surfaces of the outer casing body, respectively, in the upper bearing mounting seat and the lower bearing mounting seat Directly mount the disc spiramogram, in the disk shaft, a striped disc; the lower sleev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com