Transformer oil gas content testing device and a transformer oil gas content testing method and device for measuring density through U-shaped oscillation tube

A transformer oil and testing device technology, applied in measuring devices, specific gravity measurement, instruments, etc., can solve the problems of low measurement results, reduced gas phase gas component concentration, undetectable gas, etc., achieve high measurement accuracy, simple operation, avoidance of The effect of gas redissolving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

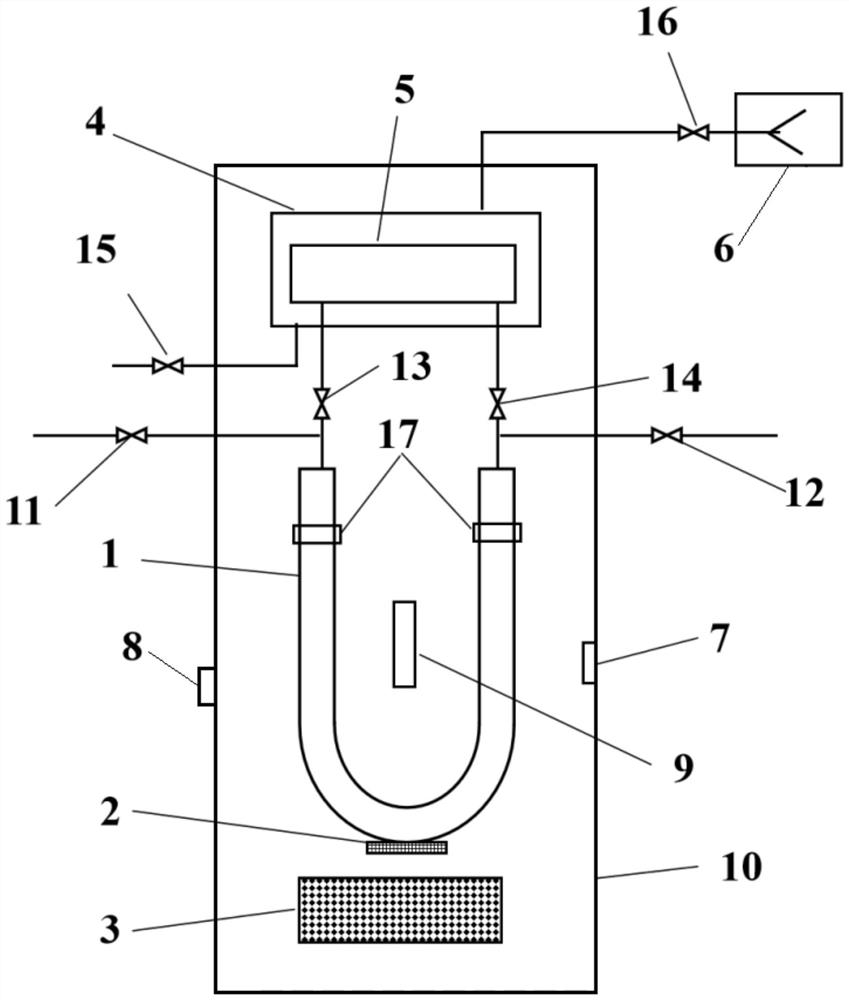

[0053] 1. The connection relationship of the device

[0054] Such as figure 1 As shown, a U-shaped oscillating tube density measuring transformer oil gas content testing device includes: U-shaped oscillating tube 1, magnet 2, electronic excitation oscillator 3, vacuum degassing chamber 4, oil sample buffer chamber 5, vacuum pump 6 , the first temperature sensor 7, the second temperature sensor 8, the third temperature sensor 9, the temperature control insulation layer 10, the first valve 11, the second valve 12, the third valve 13, the fourth valve 14, the fifth valve 15, Sixth valve 16, frequency counter 17.

[0055] The U-shaped oscillating tube 1, magnet 2, electronic excitation oscillator 3, vacuum degassing chamber 4, oil sample buffer chamber 5, first temperature sensor 7, third temperature sensor 9, third valve 13, fourth valve 14. The frequency counter 17 is installed inside the temperature control insulation layer 10; the U-shaped oscillating tube 1 is made of boron...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com