Gate valve for radiation protection

A technology of radiation protection and plug-in valve, which is applied to sliding valves, valve details, valve devices, etc., can solve the problems of difficult installation and movement, inflexible protective measures, and no radiation protection, and achieve the effect of easy installation and movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

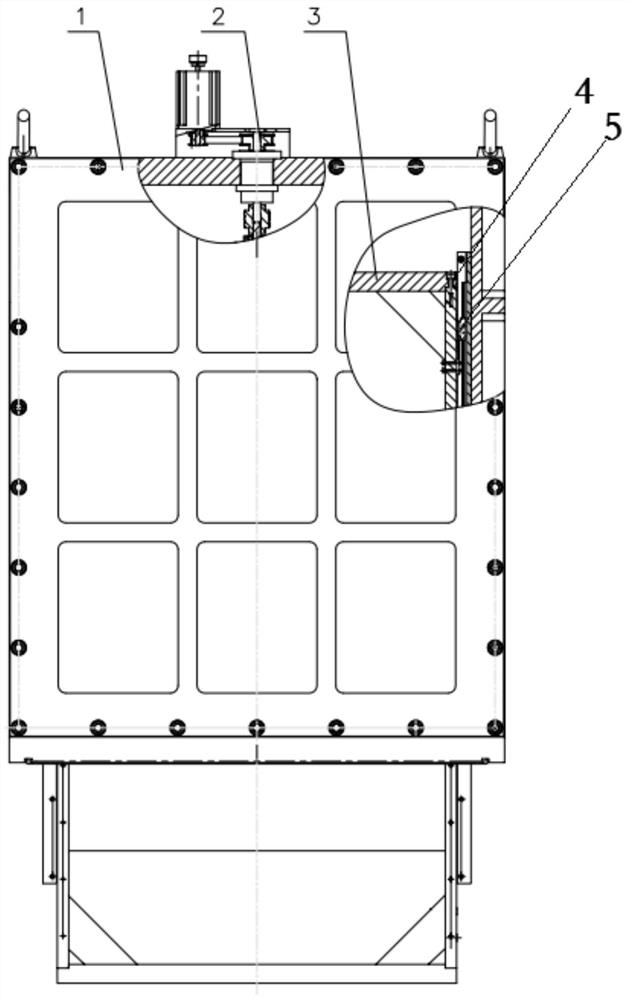

[0036] Specific implementation mode one: combine Figure 1 to Figure 12 Describe this embodiment, a gate valve for radiation protection described in this embodiment includes a housing 1, a drive unit 2, a radiation protection gate valve core 3, a slider 4, a slide rail 5, and a magnetic switch device 6 and bonnet 7;

[0037] The casing 1 is in the shape of a cuboid, and there are slide rails 5 on both sides of the inside of the casing 1, and each slide rail 5 is provided with a slider 4, and the top end of the radiation protection plugboard valve core 3 is inserted into the casing 1. Inside the cavity, and one side of the radiation protection gate valve core 3 is fixedly connected with a slider 4, the other side of the radiation protection gate valve core 3 is fixedly connected with another slider 4, and the side of the housing 1 is provided with There is a valve cover 7, and the middle part of the upper surface of the housing 2 is provided with a driving unit 2, after the ou...

specific Embodiment approach 2

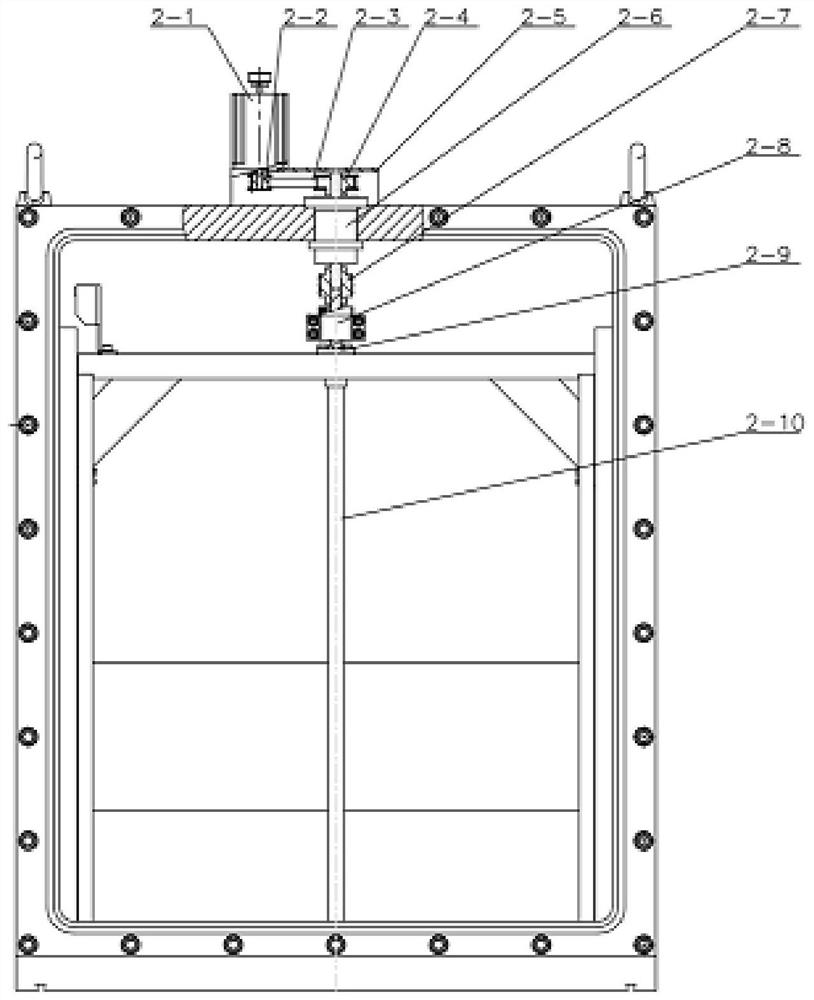

[0040] Specific implementation mode two: combination image 3 Describe this embodiment. This embodiment is a further limitation on the valve described in Embodiment 1. In this embodiment, a flapper valve for radiation protection, the drive unit 2 includes a motor 2- 1. Driving pulley 2-2, belt 2-3, driven pulley 2-4, motor seat 2-5, sealing device 2-6, coupling 2-7, bearing seat 2-8, screw nut 2 -9 and screw mandrel 2-10;

[0041] One end of the upper surface of housing 1 is provided with a motor seat 2-5, is provided with a motor 2-1 on the motor seat 2-5, is provided with a driving pulley 2-2 on the output shaft of motor 2-1, and the housing 1 is provided with a through hole in the middle of the upper surface, and a sealing device 2-6 is embedded inside the through hole, a driven pulley 2-4 is provided on the top of the transmission shaft, and the bottom end of the transmission shaft passes through the sealing device 2-6 After that, connect the top of the screw mandrel 2-1...

specific Embodiment approach 3

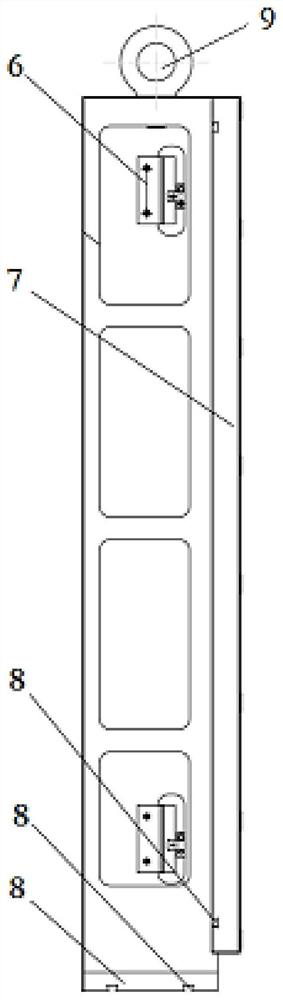

[0043] Specific implementation mode three: combination figure 2 Describe this embodiment. This embodiment is a further limitation on the valve described in Embodiment 1. In this embodiment, a gate valve for radiation protection is described. The radiation protection gate valve core 3 The bottom is provided with a plurality of sealing rings 8;

[0044] In this specific embodiment, a plurality of sealing rings 8 are arranged at the bottom of the radiation protection gate valve core 3 to improve the sealing performance of the device. The radiation protection gate valve mechanism has a sealing function and can work under atmospheric conditions or in Vacuum, pressure, etc. require a sealed environment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com