Management system of environmental sanitation vehicle

A management system and vehicle technology, applied in the field of sanitation vehicle management system, to achieve recycling, improve cooling effect, and uniform cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

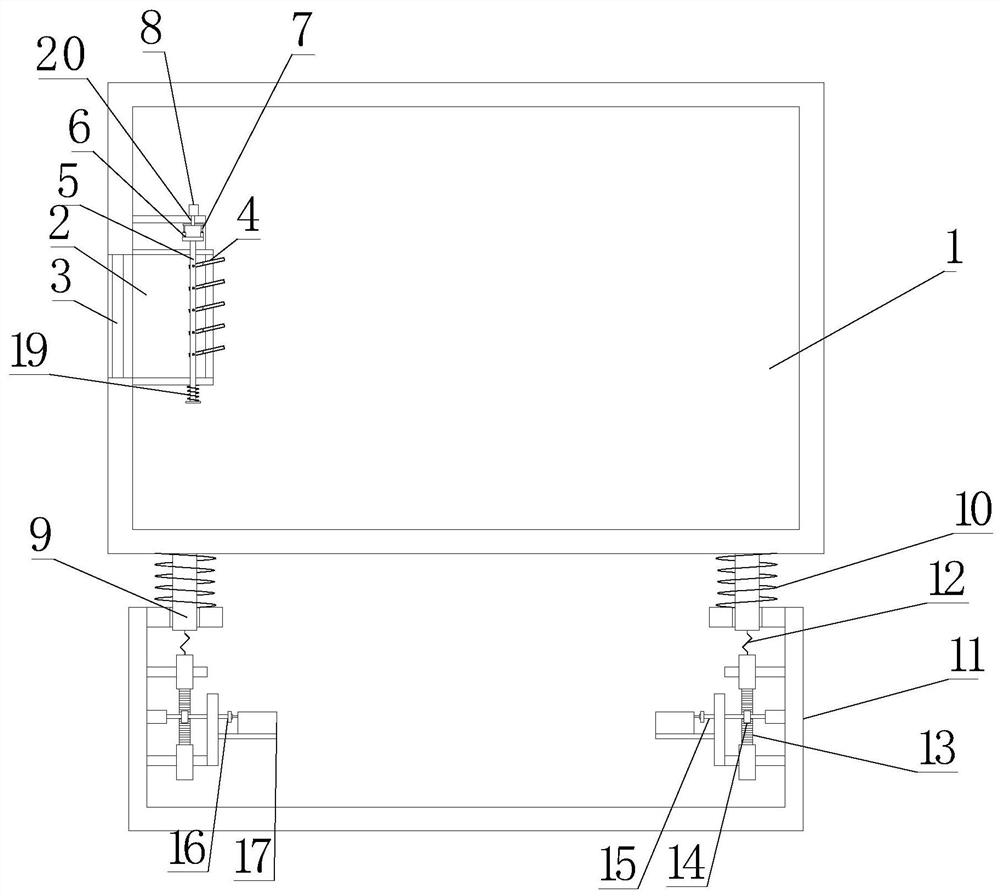

[0027] see Figure 1~2 , in Embodiment 1 of the present invention, it is a structural diagram of a sanitation vehicle management system provided by the embodiment of the present invention, including: a casing 1 and a base 11, wherein the interior of the casing 1 is provided for installing control components; The housing 1 is installed on the base 11;

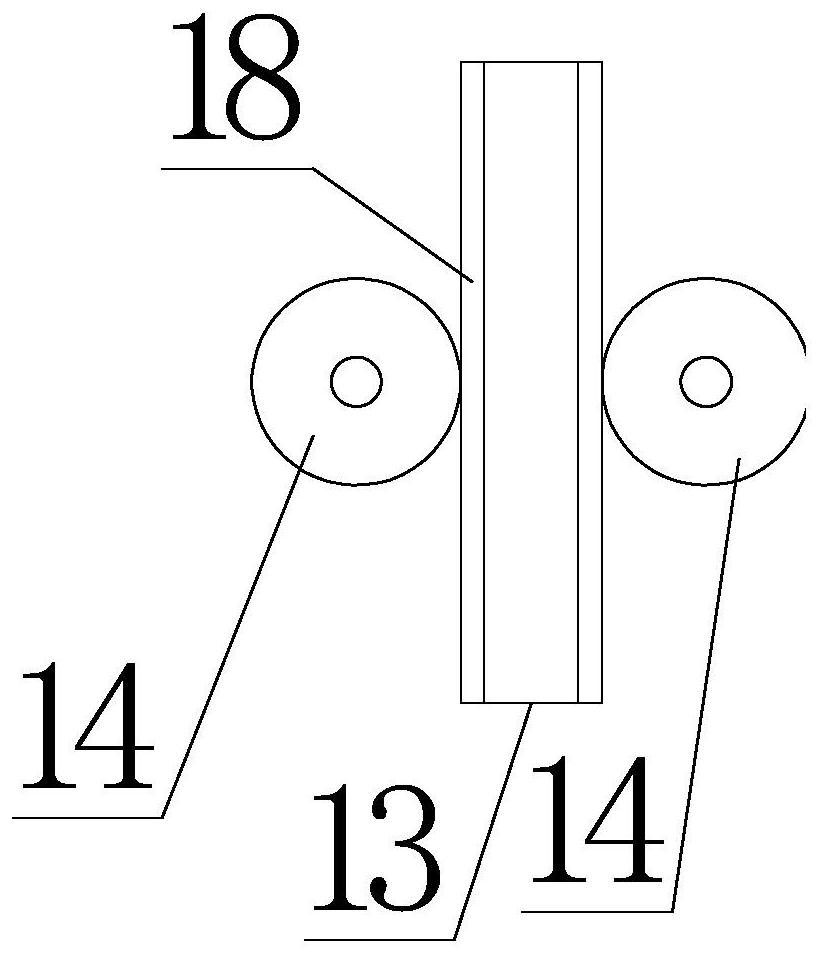

[0028] The casing 1 is provided with an air inlet 2, and the outlet of the air inlet 2 is provided with a plurality of reciprocating swing leaves 4 in an array, which are used to allow the cooling air to swing and change directions to enter the inside of the casing 1; Both sides of the bottom of the housing 1 are fixedly equipped with connecting rods 9, the connecting rods 9 pass through the sliding holes on the base 11, and the connecting rods 9 are elastically arranged on the base 11 for shock absorption; the connecting rods 9 It is connected with the slide bar 13 which is slid up and down on the base 11. Both sides of the sl...

Embodiment 2

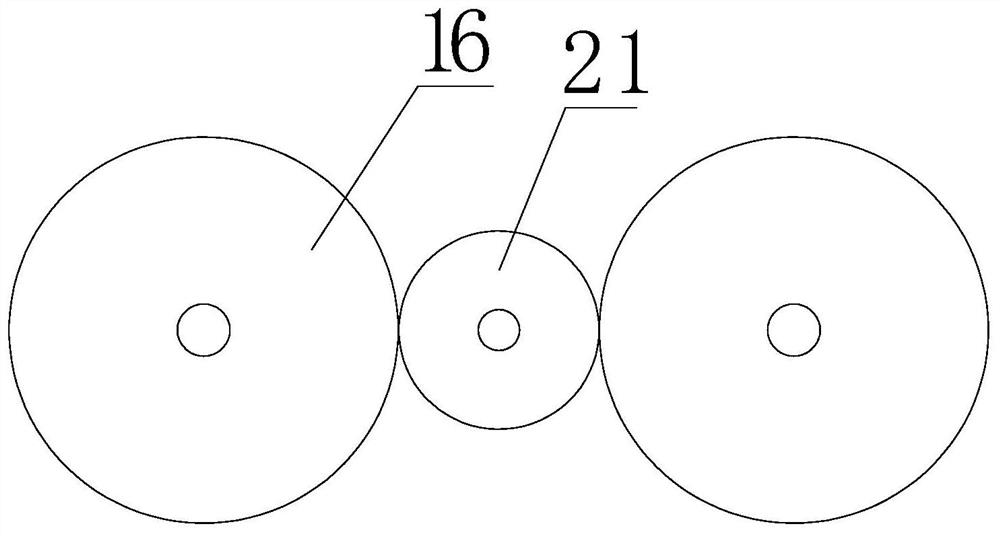

[0031] see Figure 1~4 , the main difference between this embodiment 2 and embodiment 1 is that, as a preferred embodiment of the present invention, the transmission assembly includes two installation shafts 15 and two first transmission wheels 16, wherein the one-way The wheels 14 are respectively fixedly sleeved on the installation shaft 15, and the two installation shafts 15 are respectively fixedly sleeved at the end away from the one-way wheel 14, and the two first transmission wheels 16 are respectively meshed with the second transmission wheel 21, and the first The two drive wheels 21 are connected to the input end of the generator 17. Specifically, when the slide bar 13 moves downward, the rack 18 on one side drives the one-way wheel 14 on one side to rotate, and the one-way wheel 14 on one side passes through the installation shaft. 15 drives a first transmission wheel 16 to rotate, the first transmission wheel 16 provides power for the rotation of the generator 17 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com