A kind of water-based two-component polyurethane matte coating and its preparation method and application

A water-based two-component, polyurethane technology, applied in the field of coatings, can solve problems affecting the water resistance of coatings, and achieve the effects of improving flexibility, reducing costs, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

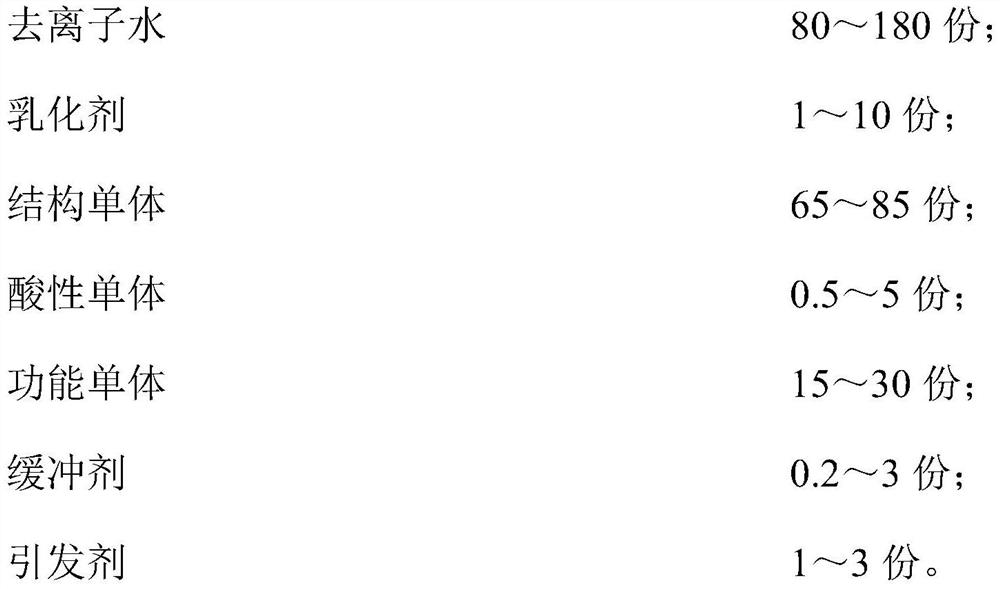

[0089] In this embodiment, a water-based two-component polyurethane matte coating is provided, and the water-based two-component polyurethane matte coating includes A component and B component, and the preparation raw materials of the A component include the following parts by weight Components:

[0090]

[0091]

[0092] The raw materials of the B component include the following components in parts by weight:

[0093] Covestro 307 water-based curing agent 0.1 part.

[0094] Among them, the solid content of the hydroxyacrylate emulsion is 35%, the hydroxyl content is 2%, and the particle size of the rutile titanium dioxide is 500 mesh.

[0095] The raw materials for the preparation of the hydroxyacrylate emulsion include the following components in parts by weight:

[0096]

[0097] The preparation method of described hydroxyacrylate emulsion comprises the following steps:

[0098] (1) Preparation of pre-emulsion

[0099] Put 30 parts of deionized water and 0.5 pa...

Embodiment 2

[0111] In this embodiment, a water-based two-component polyurethane matte coating is provided, and the water-based two-component polyurethane matte coating includes A component and B component, and the preparation raw materials of the A component include the following parts by weight Components:

[0112]

[0113]

[0114] The raw materials of the B component include the following components in parts by weight:

[0115] Covestro 307 water-based curing agent 5 parts.

[0116] Among them, the solid content of the hydroxyacrylate emulsion is 55%, the hydroxyl content is 4%, and the particle size of the rutile titanium dioxide is 1000 mesh.

[0117] The raw materials for the preparation of the hydroxyacrylate emulsion include the following components in parts by weight:

[0118]

[0119] The preparation method of described hydroxyacrylate emulsion comprises the following steps:

[0120] (1) Preparation of pre-emulsion

[0121] Put 30 parts of deionized water and 0.5 part...

Embodiment 3

[0133] In this embodiment, a water-based two-component polyurethane matte coating is provided, and the water-based two-component polyurethane matte coating includes A component and B component, and the preparation raw materials of the A component include the following parts by weight Components:

[0134]

[0135]

[0136] The raw materials of the B component include the following components in parts by weight:

[0137] Covestro 307 water-based curing agent 0.5 parts.

[0138] Wherein, the solid content of the hydroxyacrylate emulsion is 55%, and the hydroxyl content is 3%.

[0139] The raw materials for the preparation of the hydroxyacrylate emulsion include the following components in parts by weight:

[0140]

[0141] The preparation method of described hydroxyacrylate emulsion comprises the following steps:

[0142] (1) Preparation of pre-emulsion

[0143] Put 30 parts of deionized water and 0.5 parts of emulsifier in a pre-emulsification bottle, stir evenly at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com