High-precision pneumatic power head

A power head and high-precision technology, applied in the field of power heads, can solve the problems of scrapped processed products, increased production costs, and offset of micro-product processing positions, etc., and achieve the effect of stable air kinetic energy and high drill speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

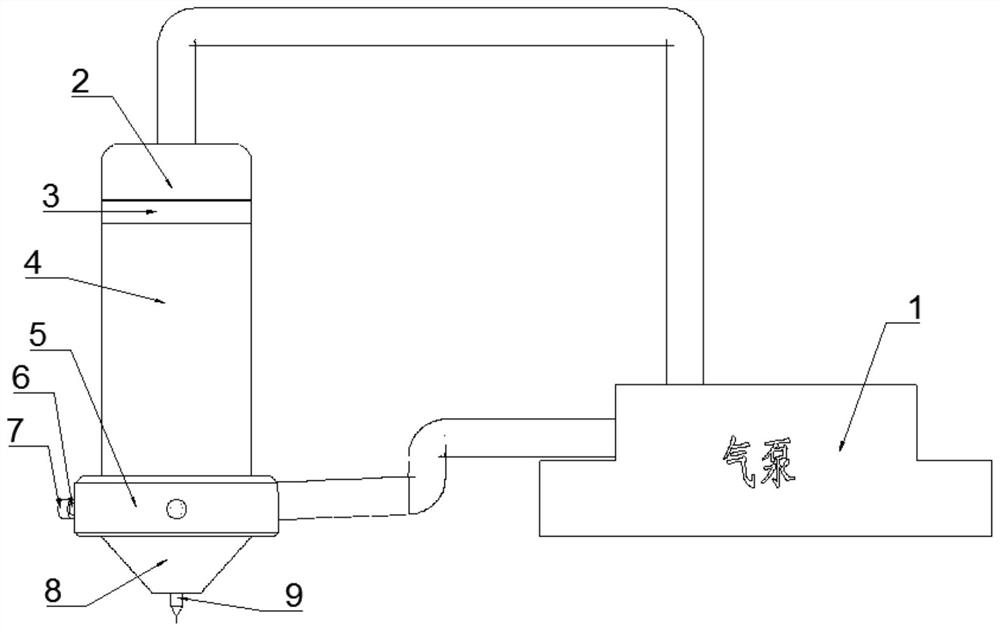

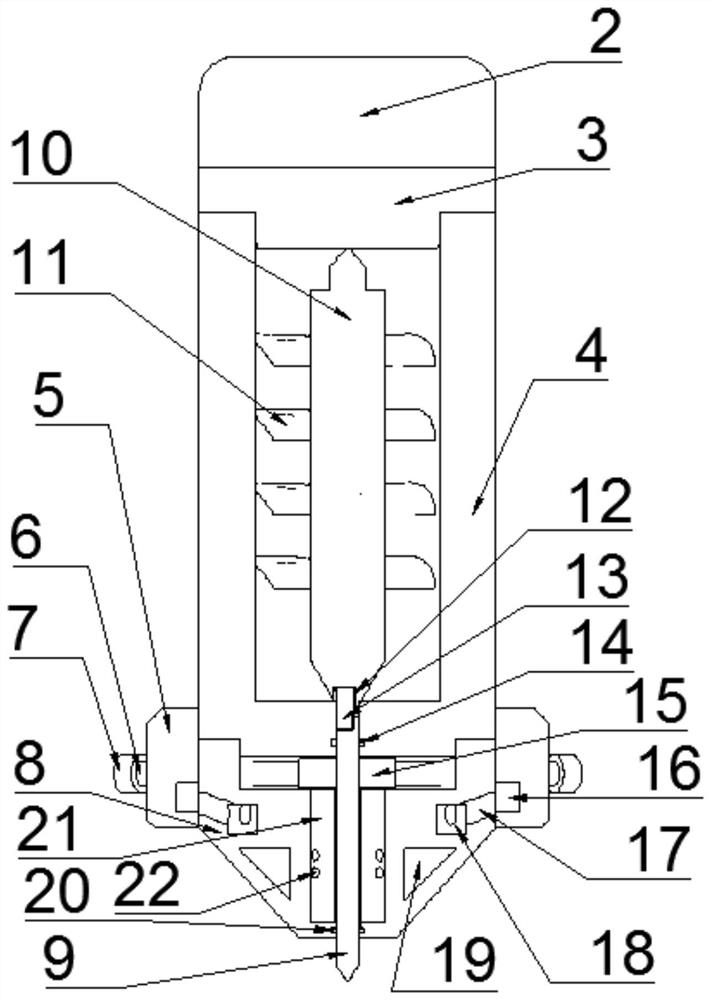

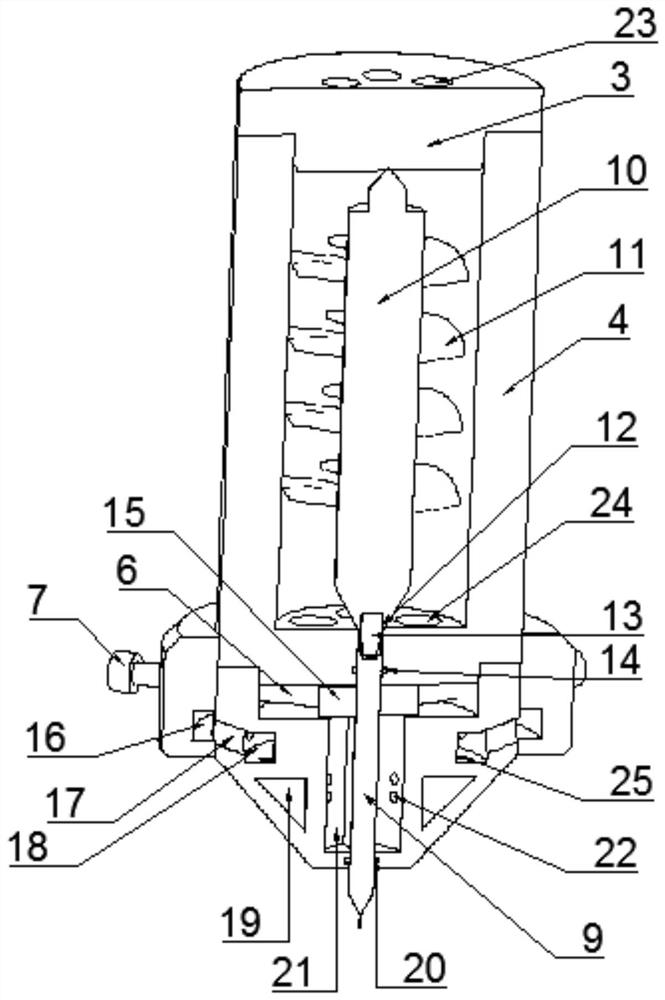

[0025] Such as Figure 1 to Figure 3 As shown, in the specific present embodiment, a high-precision pneumatic power head includes a power bushing 4, a driving assembly arranged in the power bushing 4, a drill assembly arranged at the bottom of the driving assembly, and the driving assembly includes a power shaft 10. Coupling 13, upper cover 3, air cover 2 and air pump 1. Upper cover 3 is fixedly connected to the top of power bushing 4. Upper cover 3 is provided with a plurality of ventilation holes 23. Air cover 2 is located at the top of upper cover 3. , the air pump 1 is connected to the air cover 2 through a pipeline, the power shaft 10 is built in the power shaft sleeve 4, the shaft body of the power shaft 10 is cylindrical, and both ends of the shaft are conical. The impeller 11, the middle part of the bottom end of the power shaft sleeve 4 is provided with a connecting through hole, the upper end of the power shaft 10 is inserted into the middle inner wall of the upper c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com