Optimization method of high back pressure heat supply for thermal power units

An optimization method and technology of thermoelectric units, applied in heating methods, household heating, heating fuel, etc., can solve problems such as unoptimized unit back pressure, minimize heating energy consumption, ensure heat load demand, and increase power generation volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

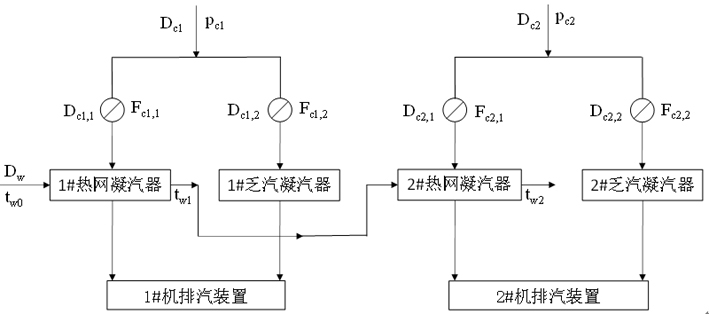

[0105] as attached figure 1 As shown, a collaborative optimization method for high back pressure heating of two thermal power units is implemented, and the temperature is t w0 , the flow is D w The circulating return water of the primary heat network flows through the 1# heat network condenser and the 2# heat network condenser in turn, and the pressure in the 1# heat network condenser is p c1 , the flow is D c1,1 The 1# machine exhaust steam is heated to t w1 , in the 2# heat network condenser, the pressure is p c2 , the flow is D c2,1 The 2# machine exhaust steam is heated to t w2 , the high back pressure heating optimization embodiment of the present invention is as follows:

[0106] First, implement the operation of the 1# unit under the optimal back pressure and adjust the back pressure of the 2# unit p c2 Guaranteed water temperature t w2 optimization scheme; according to the exhaust steam flow of 1# unit D c1 and ambient temperature T 0 Calculate th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com