Y-shaped tunnel grouting structure and matched grouting method

A technology of grouting and tunneling, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., and can solve problems such as unsolvable segment floating phenomenon, segment floating, cumbersome construction process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

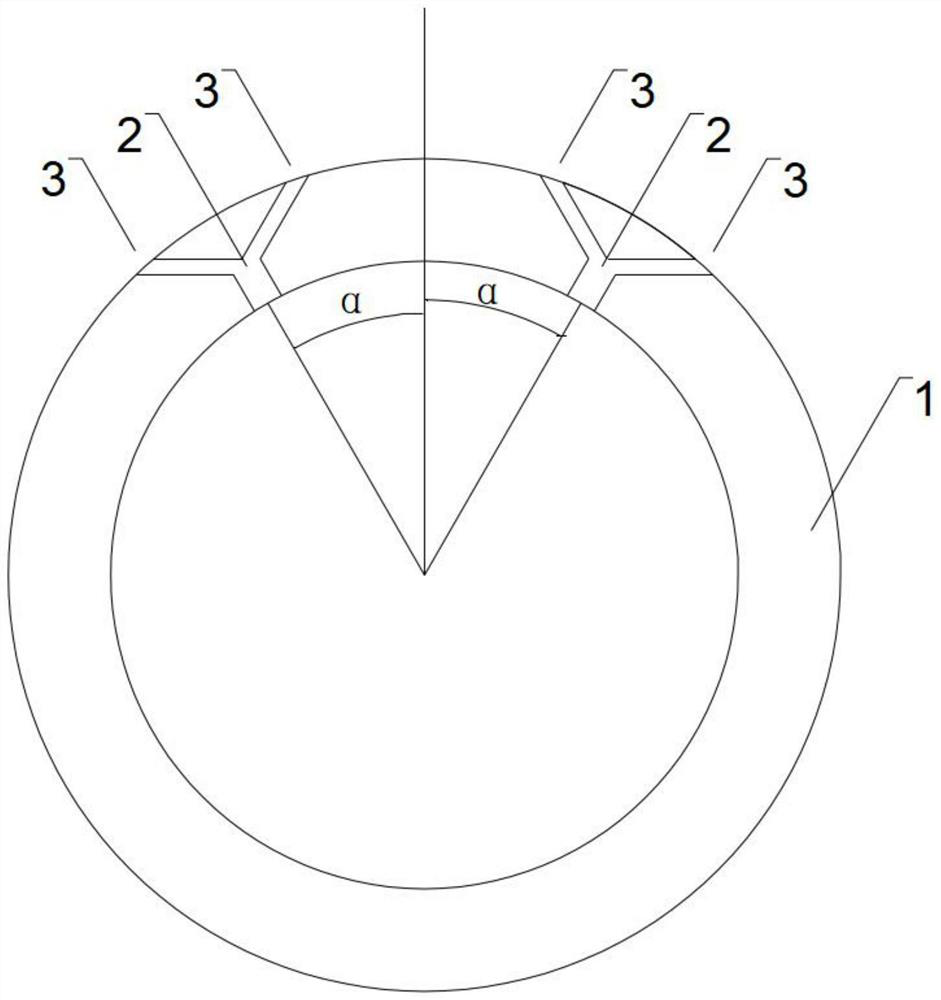

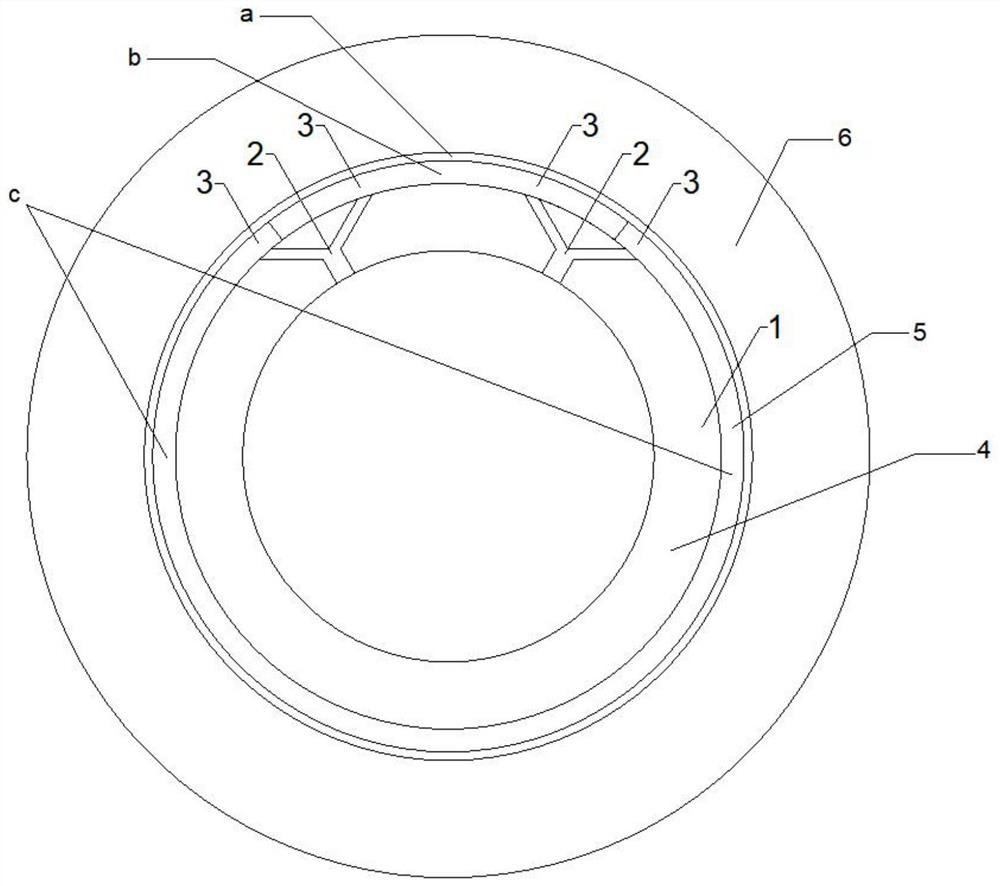

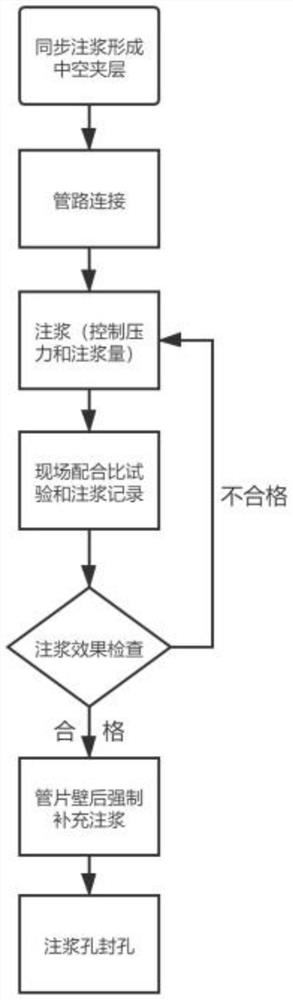

[0034] Embodiment 1: A kind of grouting structure in tunnel excavation process, please refer to figure 1 and figure 2 , the embodiment of the present invention includes:

[0035] From the tunnel rock layer 6, it includes the rock layer 6, the grouting layer and the pipe layer 4 in sequence. The pipe layer 4 is provided with a grouting hole, and the grouting hole is grouted outward. The surface of the rock layer 6 is formed by synchronous grouting. A hard shell, forming a grouting layer between the hard shell and the segment layer 4; a pair of Y-shaped pre-grouting holes 2, Y The reserved hole 2 for grouting has two pipes for spraying slurry upward and downward; the reserved hole 2 for Y-shaped grouting sprays liquid A upward, and the reserved hole 2 for Y-shaped grouting sprays liquid B downward; Type grouting reserved hole 2 is movably connected to a grouting pipeline, and the other end of the pipeline is connected to a grouting machine injecting liquid A and liquid B resp...

Embodiment 2

[0057] Embodiment 2: A kind of grouting structure in the tunnel excavation process, please refer to figure 1 and figure 2 , the embodiment of the present invention includes:

[0058] From the tunnel rock layer 6, it includes the rock layer 6, the grouting layer and the pipe layer 4 in sequence. The pipe layer 4 is provided with a grouting hole, and the grouting hole is grouted outward. The surface of the rock layer 6 is formed by synchronous grouting. A hard shell, forming a grouting layer between the hard shell and the segment layer 4; a pair of Y-shaped grouting reserved holes 2, Y The reserved hole 2 for grouting has two pipes for spraying slurry upward and downward; the reserved hole 2 for Y-shaped grouting sprays liquid A upward, and the reserved hole 2 for Y-shaped grouting sprays liquid B downward; Type grouting reserved hole 2 is movably connected to a grouting pipeline, and the other end of the pipeline is connected to a grouting machine injecting liquid A and liqu...

Embodiment 3

[0072] Embodiment 3: A kind of grouting structure in the process of tunnel excavation, please refer to figure 1 and figure 2 , the embodiment of the present invention includes:

[0073] From the tunnel rock layer 6, it includes the rock layer 6, the grouting layer and the pipe layer 4 in sequence. The pipe layer 4 is provided with a grouting hole, and the grouting hole is grouted outward. The surface of the rock layer 6 is formed by synchronous grouting. A hard shell, forming a grouting layer between the hard shell and the segment layer 4; a pair of Y-shaped pre-grouting holes 2, Y The reserved hole 2 for grouting has two pipes for spraying slurry upward and downward; the reserved hole 2 for Y-shaped grouting sprays liquid A upward, and the reserved hole 2 for Y-shaped grouting sprays liquid B downward; Type grouting reserved hole 2 is movably connected to a grouting pipeline, and the other end of the pipeline is connected to a grouting machine injecting liquid A and liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com