A production process of 8011 decorative strip

A production process and decorative tape technology, applied in the direction of metal rolling, etc., can solve the problems of less Hazlett process, surface segregation and holes, etc., and achieve the effects of shortening the production cycle, fine grains and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

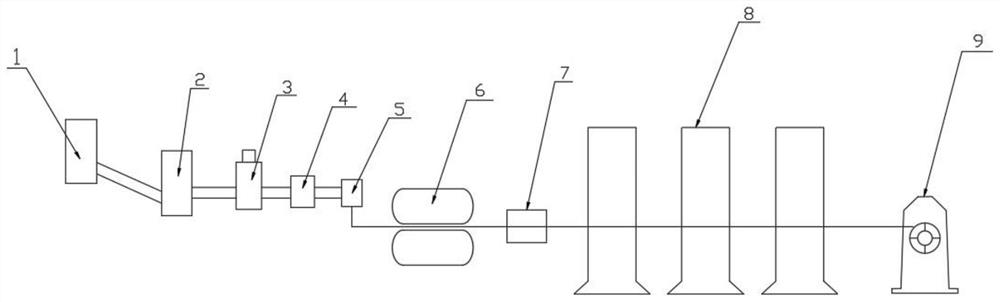

[0026] A production process of 8011 decorative tape, the composition and mass percentage of the decorative tape are: Fe0.82%, Si 0.58%, Cu 0.038%, Ti 0.022%, Mn≤0.01%, Mg≤0.01%, The balance is Al, such as figure 1 As shown in the processing system of 8011 decorative strips, the production process includes the following steps:

[0027] ①Smelting: use 70% electrolytic aluminum liquid and 30% solid material as alloy ingredients, add the solid material first, then add the electrolytic aluminum liquid, the melting temperature is 725-730 ° C, one-time sampling inspection, according to the inspection Results Adding iron agent, manganese agent, aluminum-silicon alloy, aluminum-titanium alloy, the alloy addition temperature was 725-740 ℃, and the aluminum alloy liquid was obtained; the solid material included aluminum ingot and 8011 aluminum alloy waste.

[0028] ② Refining: Refining the molten aluminum alloy three times; refining once: raising the temperature of the molten aluminum a...

Embodiment 2

[0035] A production process of 8011 decorative tape, the composition and mass percentage of the decorative tape are: Fe0.80%, Si0.60%, Cu0.038%, Ti0.025%, Mn≤0.01%, Mg≤0.01%, The balance is Al, such as figure 1 As shown in the processing system of 8011 decorative strips, the production process includes the following steps:

[0036] ①Smelting: use 70% electrolytic aluminum liquid and 30% solid material as alloy ingredients, add the solid material first, then add the electrolytic aluminum liquid, the melting temperature is 725-730 ° C, one-time sampling inspection, according to the inspection Results Adding iron agent, manganese agent, aluminum-silicon alloy, aluminum-titanium alloy, the alloy addition temperature was 725-740 ℃, and the aluminum alloy liquid was obtained; the solid material included aluminum ingot and 8011 aluminum alloy waste.

[0037] ② Refining: Refining the molten aluminum alloy three times; refining once: raising the temperature of the molten aluminum allo...

Embodiment 3

[0044] A production process of 8011 decorative tape, the composition and mass percentage of the decorative tape are: Fe0.81%, Si 0.60%, Cu 0.043%, Ti 0.031%, Mn≤0.01%, Mg≤0.01%, The balance is Al, such as figure 1 As shown in the processing system of 8011 decorative strips, the production process includes the following steps:

[0045] ①Smelting: use 70% electrolytic aluminum liquid and 30% solid material as alloy ingredients, add the solid material first, then add the electrolytic aluminum liquid, the melting temperature is 725-730 ° C, one-time sampling inspection, according to the inspection Results Adding iron agent, manganese agent, aluminum-silicon alloy, aluminum-titanium alloy, the alloy addition temperature was 725-740 ℃, and the aluminum alloy liquid was obtained; the solid material included aluminum ingot and 8011 aluminum alloy waste.

[0046] ② Refining: Refining the molten aluminum alloy three times; refining once: raising the temperature of the molten aluminum a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com