Robot glaze spraying process for pedestal pan products

A robot and product technology, applied in the field of ceramic glaze spraying, can solve the problems of high speed, difficult to spray the real gun, glaze flowing into the hat, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

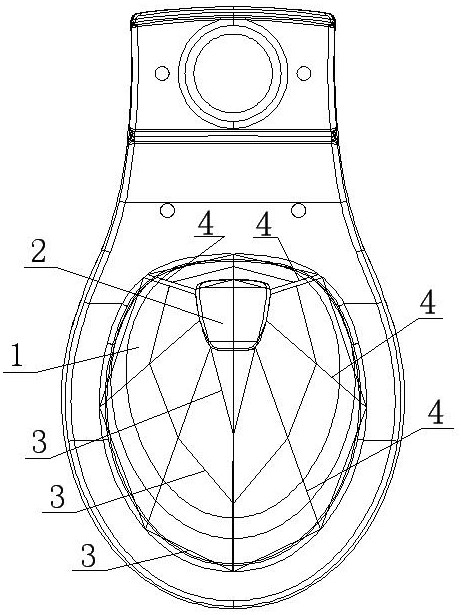

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and examples.

[0026] This embodiment is a robot glaze spraying process for toilet products. The robot is a Yaskawa GP25, the spray gun is Iwata WA200Z1P, and the dual guns are configured with two grippers. The present embodiment carries out as follows:

[0027] A. Teach the procedure of spraying glaze in the toilet pot

[0028] 1) Before teaching, draw a line in pot 1 of the toilet product ( figure 1 As shown), draw three circles of the circular line 3, the circular line 3 is composed of multiple line segments, the circular line 3 is the actual path of the robot, and the robot walks horizontally along the circular line 3, from the hat head 2 to the outer circle 10 radial lines 4 are drawn between the circumferential lines 3 of , and the radial lines 4 are used to distinguish the boundary of the line drawn in the pot 1 and equally divide the path of the robot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com