Sludge fermentation process for pig raising wastewater

A wastewater sludge and fermentation process technology, which is applied in the field of swine wastewater sludge fermentation process, can solve the problems of slow hydrolysis and acidification, chemical pollution, high energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

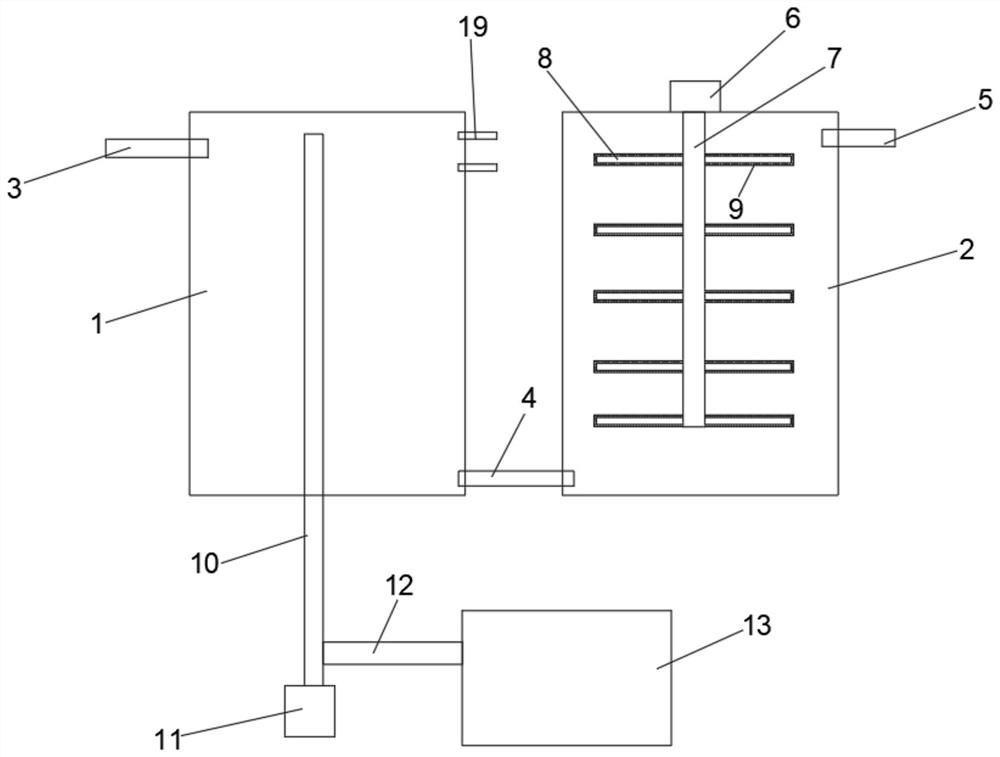

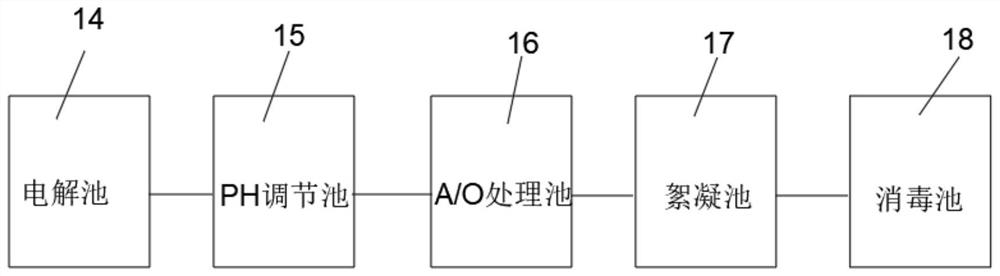

[0027] Such as Figure 1-Figure 2 As shown, the invention provides a kind of pig raising wastewater sludge fermentation process,

[0028] From left to right, it includes a sedimentation tank 1 and a fermentation tank 2. The upper side wall of the sedimentation tank 1 is provided with a feed pipe 3, and the feed pipe 3 can pass waste water sludge into the sedimentation tank 1. , the settling tank 1 can carry out sedimentation and stratification of wastewater sludge, the upper layer in the settling tank 1 is waste water, the lower layer is sludge, the lower end of the settling tank 1 and the lower end of the fermentation tank 2 pass through the feed pipe 4 connected, the feed pipe 4 can pass the lower sludge in the settling tank 1 into the fermenter 2, the settling tank 1 is provided with a waste water collection device, and the waste water collection device can transfer the The upper layer waste water in the settling tank 1 is discharged and collected;

[0029] The side wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com