Method and system for defluorinating mine water

A technology of mine water and fluoride removal agent, which is applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., and can solve the problems of low resource utilization rate, burden, and resource utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

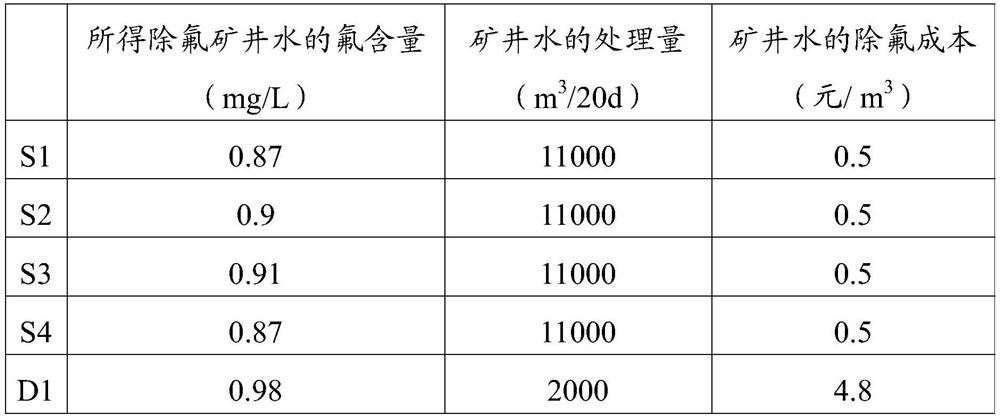

Embodiment 1

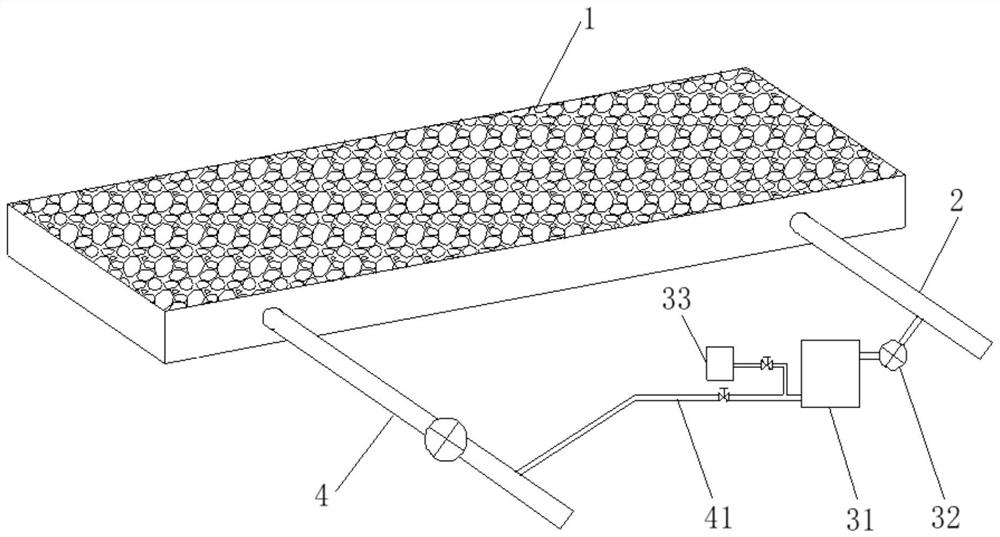

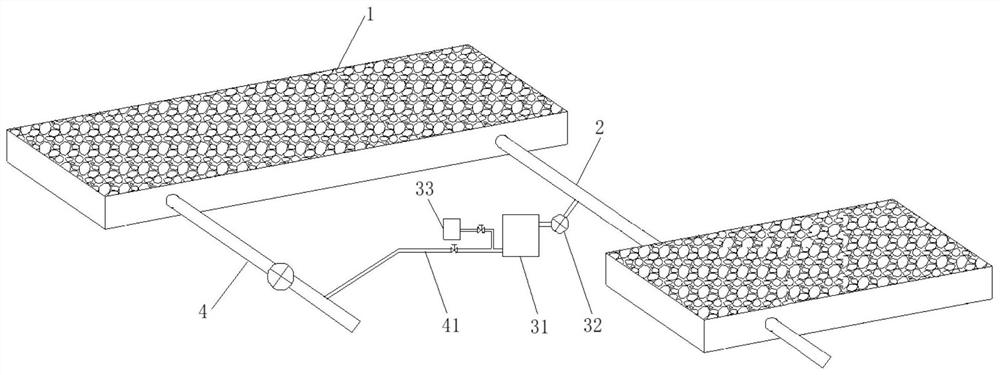

[0096] The outflow of mine water in Shendong Shangwan coal mining area is about 11000m 3 / d, after the sedimentation and filtration treatment of the surface mine sewage plant, the fluorine content is 2mg / L, which exceeds the 1mg / l requirement of the surface type III water, adopting the method of the present invention and such as figure 2 The system shown defluorides mine water from the Shendong Shangwan Coal Mine. in,

[0097] The first underground reservoir 1 has a capacity of 240,000 m 3 , the capacity of the second underground reservoir is 200,000 m 3 ;

[0098] The mine water is introduced into the second underground reservoir through the pipeline and deposited for 20 days to obtain purified mine water located in the upper layer;

[0099] According to the quality of the fly ash, it is 0.5wt% of the quality of the mine water input into the second underground reservoir to get the fly ash, then the fly ash obtained is added to the stirring tank 31 in the fly ash adding d...

Embodiment 2

[0102] Compared with embodiment 1, only following difference:

[0103] The molar concentration of hydrochloric acid solution is 5mol / L;

[0104] The pH of the resulting mixture is 4.1-4.3;

[0105] The amount of the fly ash is 0.3wt% of the amount of mine water injected into the second underground reservoir.

Embodiment 3

[0107] Compared with embodiment 1, only following difference:

[0108] The molar concentration of hydrochloric acid solution is 1mol / L;

[0109] The pH of the resulting mixture is 4.7-4.9;

[0110] The amount of the fly ash is 0.8wt% of the amount of mine water injected into the second underground reservoir.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com