Polishing method for compressor blades of small and medium-sized aero-engines

A technology of aero-engines and compressors, which is applied in grinding/polishing equipment, grinding machines, metal processing equipment, etc., and can solve the problems of easy over-polishing and under-polishing polishing accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

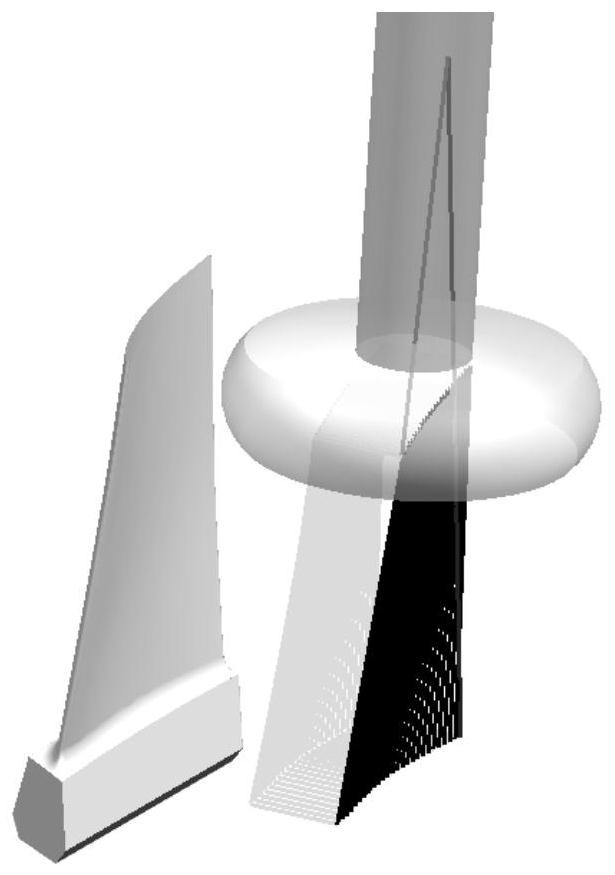

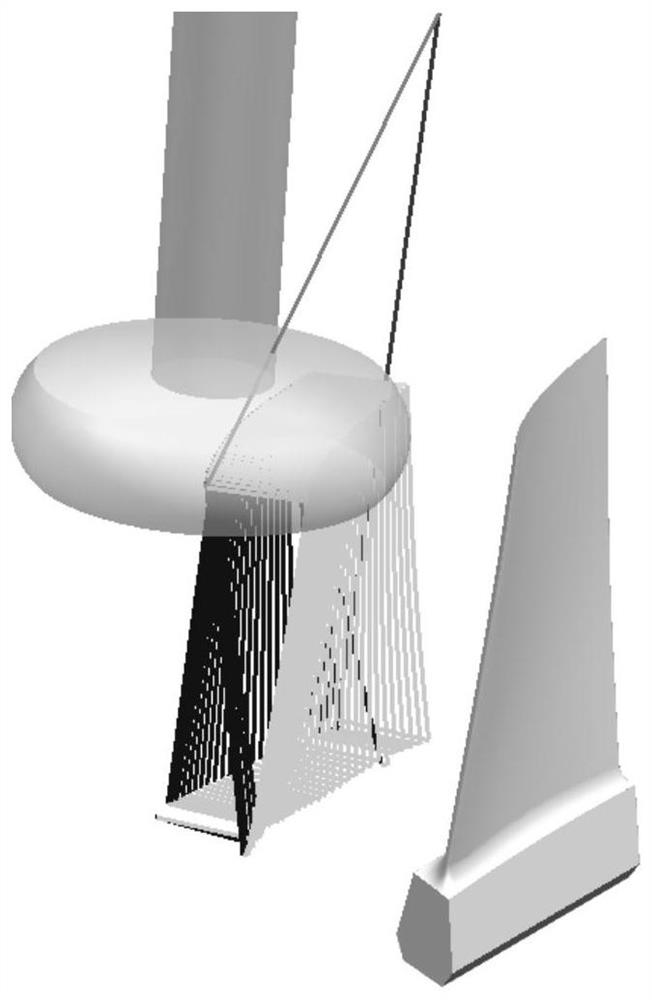

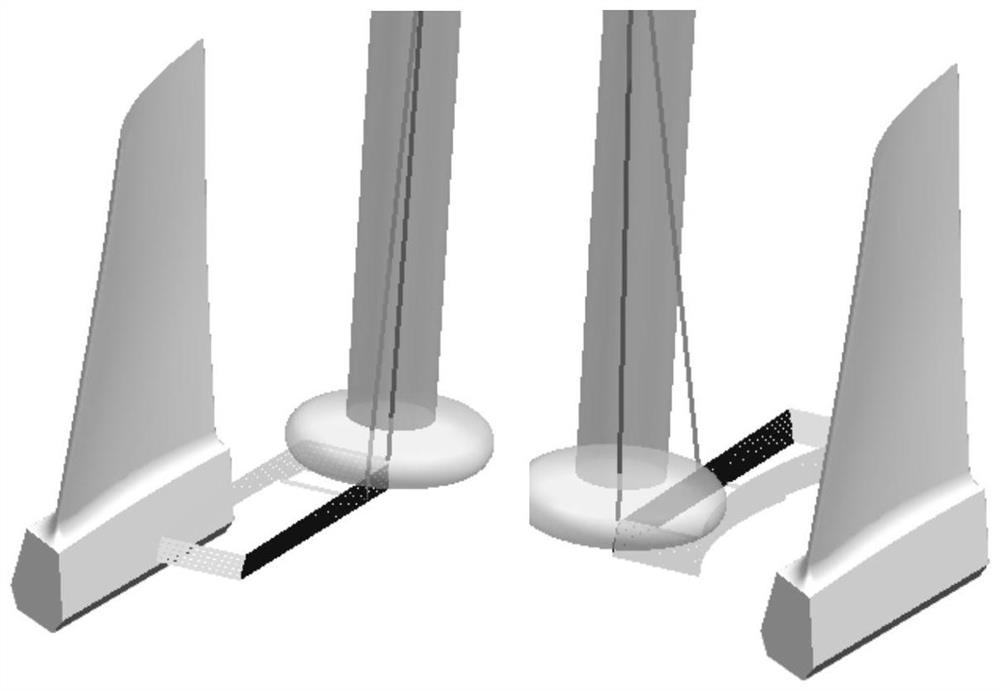

Image

Examples

Embodiment 1

[0069] A polishing method for a compressor blade of a small and medium-sized aeroengine comprises the following steps:

[0070] S1. The area division of blade polishing, according to the margin distribution of the number milling process before polishing, the difficulty of polishing the front and rear edges of the blade and the transition R of the blade root, the blade surface polishing area is divided into six areas, including the blade basin as the polishing area A. The back of the blade is the polished area B. The blade root transition R is the polished area C. The intake and exhaust edges are the polished area D. The overlap between the blade body and the intake and exhaust edges is the polished area E. The tenon flow channel is the polished area F, determine the polishing trajectory of each polishing area, comprising the following steps:

[0071] S11. Rough polishing of leaf basin and leaf back: Carry out longitudinal rough polishing in polishing area A, and move the knife...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com