Optical fiber ribbon automatic stripping equipment

A technology for stripping equipment and optical fiber ribbons, applied in the field of optical fiber cable technology, can solve the problems of large damage to the optical fiber coating, slow speed, low recycling efficiency, etc., to achieve the effect of low transformation and manufacturing costs, clean optical fiber surface, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

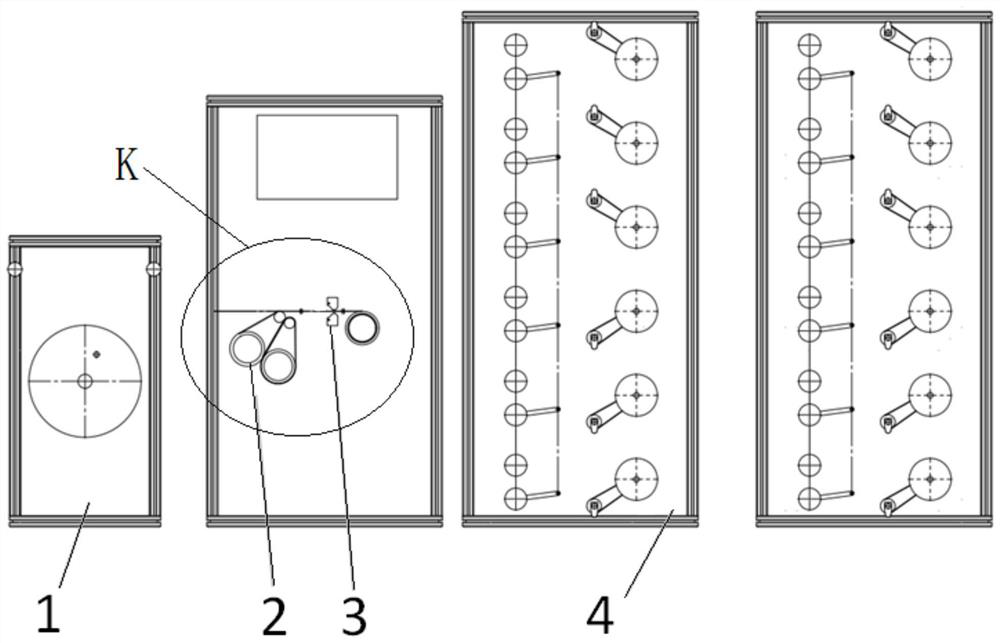

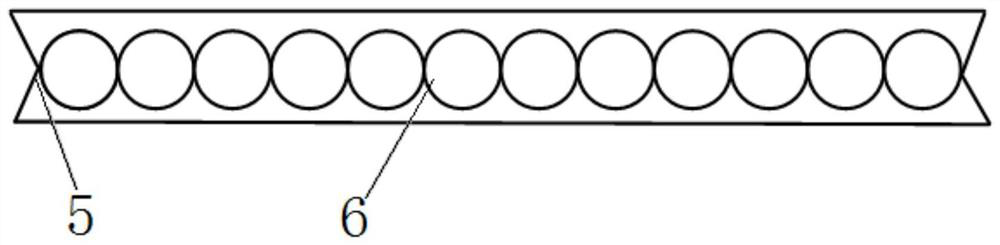

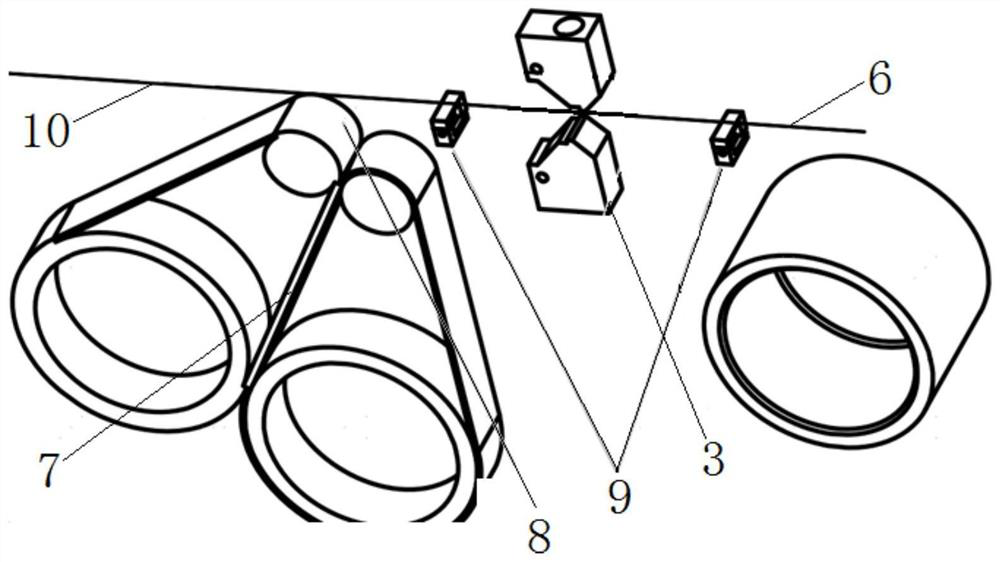

[0023] refer to Figure 1 ~ Figure 4 As shown, a kind of optical fiber ribbon automatic stripping equipment in one embodiment provided by the present invention includes an optical fiber ribbon active pay-off frame, an optical fiber ribbon stripping traction mechanism, an air knife assembly and an optical fiber take-up frame, and one end of the optical fiber ribbon is wound on the optical fiber With active pay-off frame, after the other end of the fiber ribbon passes through the fiber ribbon stripping traction mechanism, the fiber ribbon is stripped into optical fiber with resin and optical fiber. The optical fiber is divided into multiple strands of optical fiber after passing through the fiber splitting comb mode, and the multiple strands of optical fiber enter the optical fiber take-up frame respectively for winding, and the optical fiber with resin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com