Hoop type steel pipe concrete column automatic detection robot system and use method

A technology of concrete-filled steel pipe columns and robot systems, which is applied in the fields of analyzing solids using sound waves/ultrasonic waves/infrasonic waves, material analysis using sound waves/ultrasonic waves/infrasonic waves, and instruments, and can solve the problems of high construction experience requirements, high risk of concrete-filled steel pipe columns, and Manual detection of problems such as slow speed of steel pipe concrete columns, to overcome the inability to climb automatically, easy to learn and use, and avoid casualties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

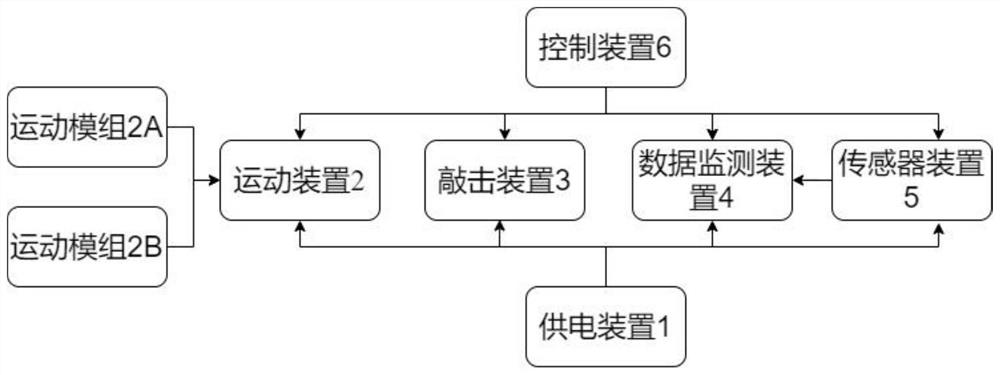

Method used

Image

Examples

Embodiment 1

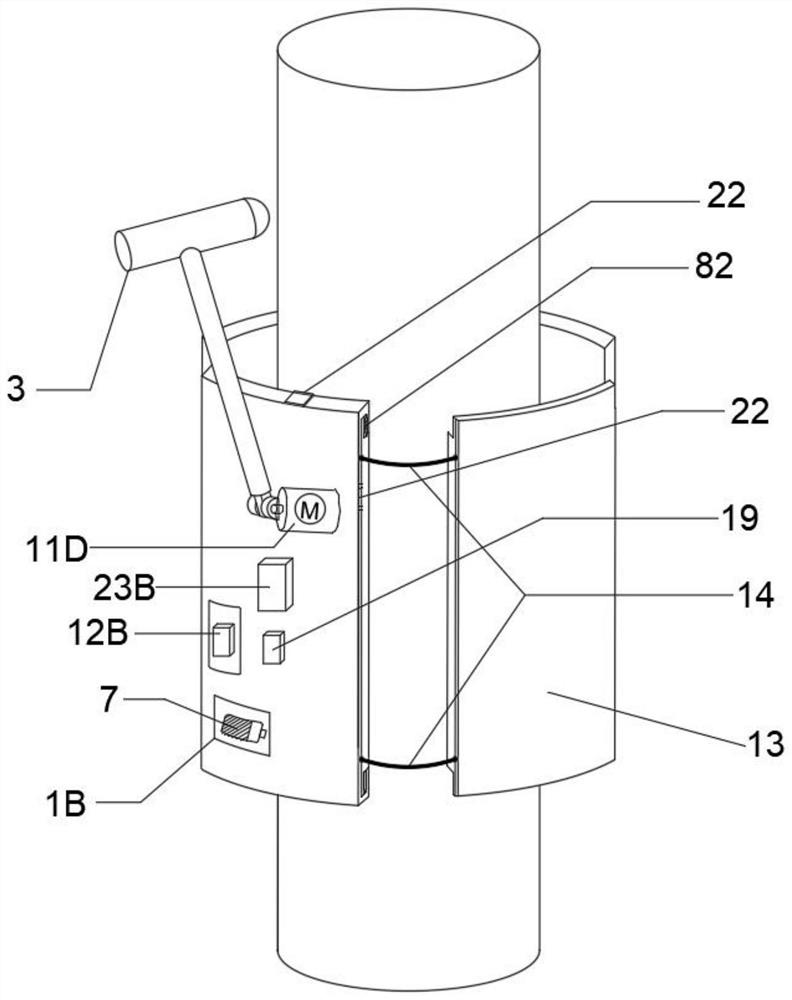

[0090] In this embodiment, the Jiaozuo Memorial Hall of the South-to-North Water Diversion Project is taken as an example. The memorial hall has 3 floors above ground and 1 floor underground, and the storey heights are 6.0m, 7.5m, 7.5m and 4.9m respectively. The memorial hall adopts steel pipe concrete column structure as the main structure of the memorial hall, and the main structure type is steel frame form. The specifications and dimensions of the concrete-filled steel tube columns in the Memorial Hall are: This example uses The column height is 6.0m as an example.

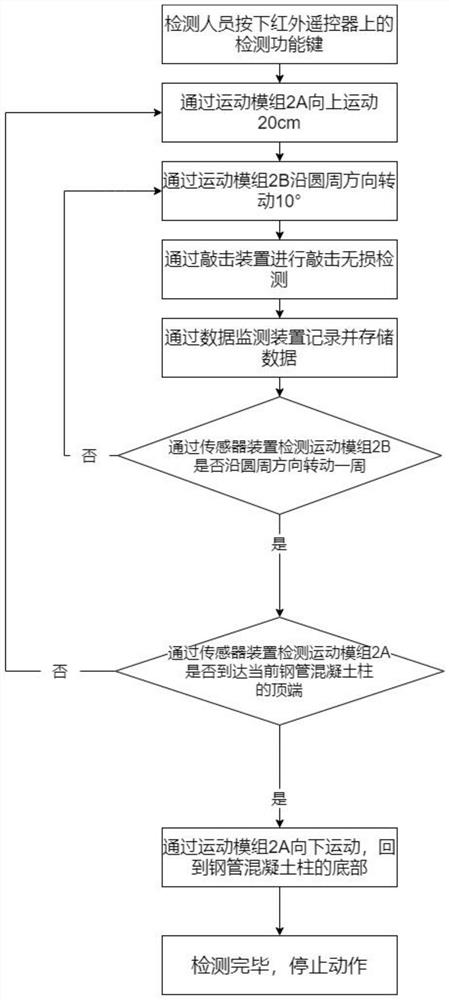

[0091] When inspectors need to knock on the concrete-filled steel pipe column, the hoop-type concrete-filled steel pipe column automatic detection robot is taken out, and the number of passive traveling patches is flexibly selected according to the diameter of the steel-filled steel pipe concrete column to be tested. Adopt the form of 1 active travel patch 9 and N passive travel patches 13, pass the steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com