Early dismantling device suitable for various standard profiles

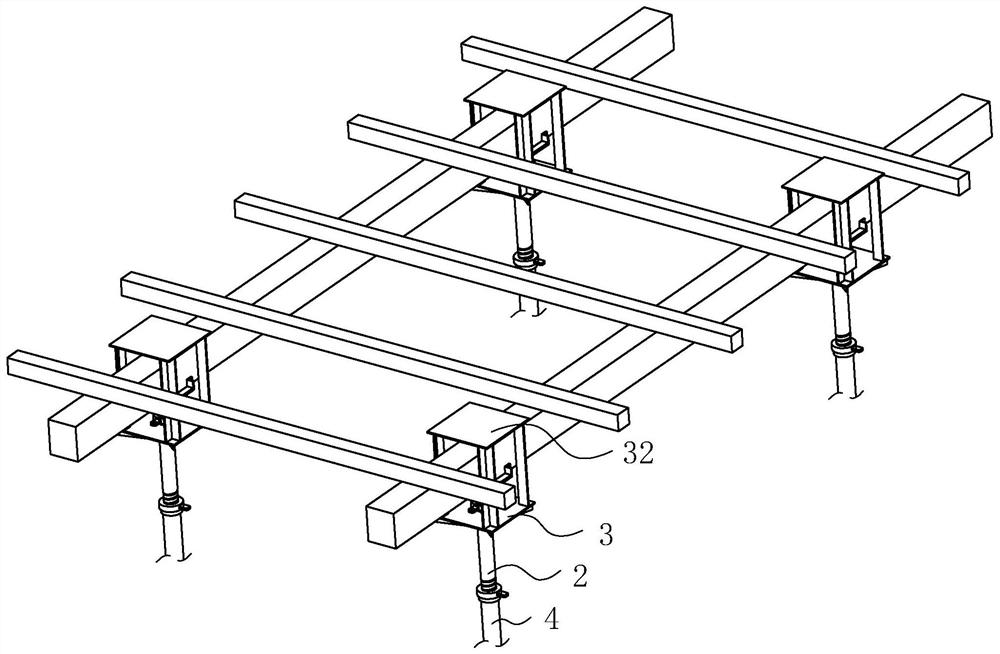

A technology of standard profiles and edge positions, which is applied to the preparation of building components on site, the connection of formwork/formwork/work frame, formwork/formwork/work frame, etc. Deformation, construction safety hazards and other problems, to achieve the effect of stable support, not easy to deform, and improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

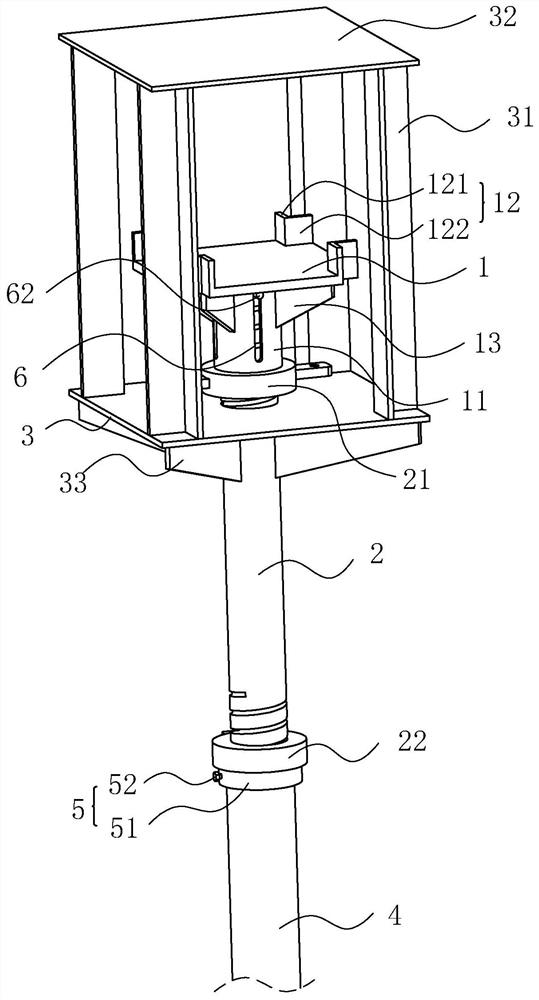

Examples

Embodiment 2

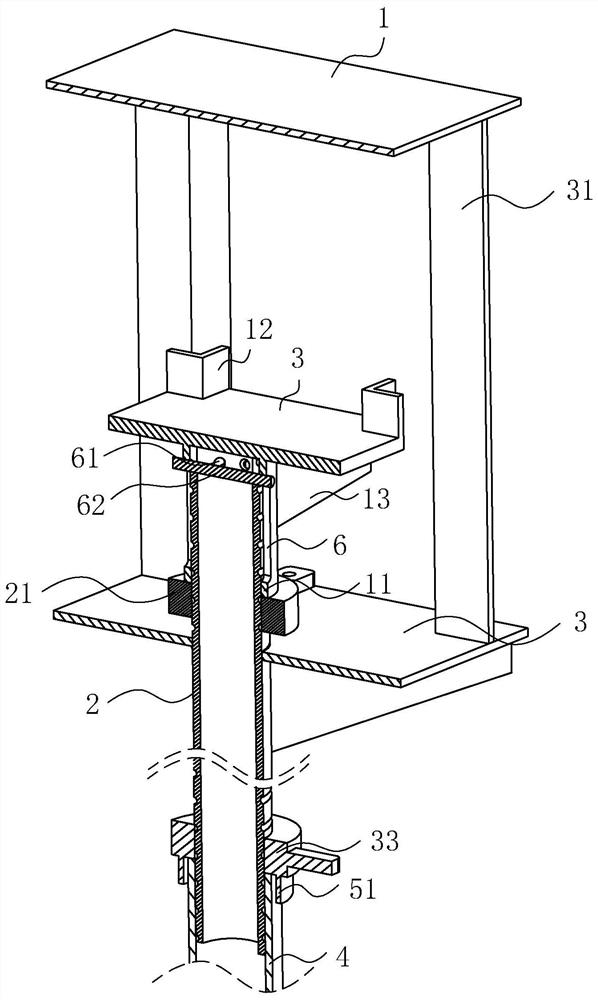

[0044] The difference with Example 1 is:

[0045] refer to Figure 4 with Figure 5 The locking assembly includes a block 7 and a tooth 72, the block 7 is slidingly connected with the threaded steel pipe 2 along the radial direction of the threaded steel pipe 2, and the block 7 is located between one end of the threaded steel pipe 2 and the inner wall of the threaded steel pipe 2 There is a spring 73, and the locking tooth 72 is pressed against by the spring 73, so that the locking tooth 72 can be kept in contact with the locking tooth 72. The locking tooth 72 is fixedly connected to the inner wall of the cylinder 11, and the length direction of the locking tooth 72 is parallel to the axial direction of the cylinder 11. A plurality of locking teeth 72 are provided and evenly distributed along the circumferential direction of the inner wall of the cylinder 11. The section of the locking teeth 72 perpendicular to the axial direction of the cylinder 11 is ratchet-shaped, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com