A detachable modular beam-column joint device and its construction method

A beam-column and node technology, which is applied in the field of modular beam-column node devices and construction, can solve the problems of low standardization, inability to replace, and low construction efficiency, and achieve the effects of less on-site operations, convenient construction, and reduced construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1: A detachable modular beam-column joint device

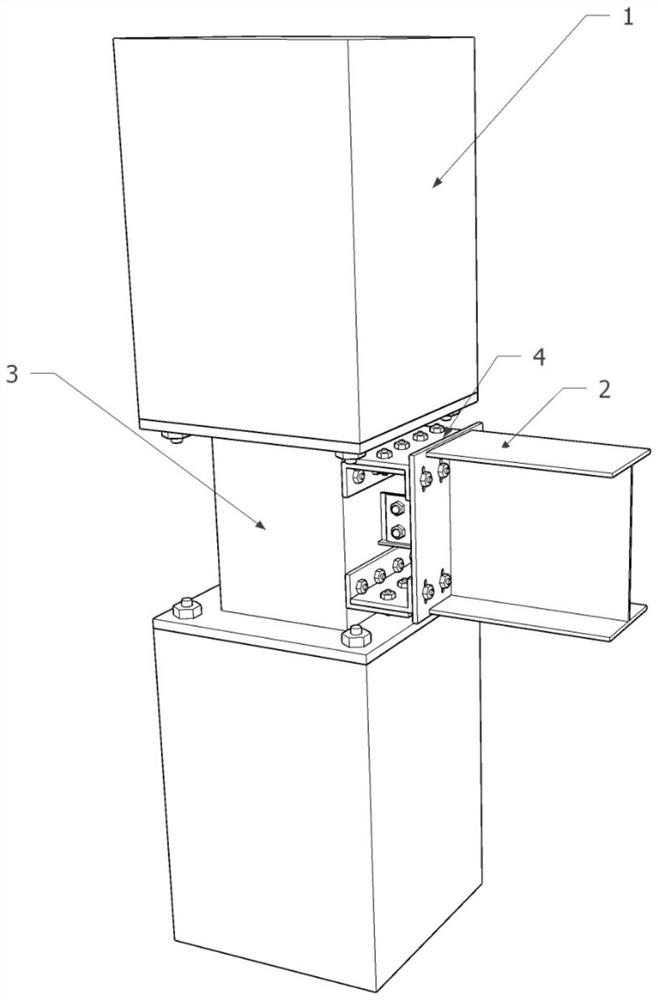

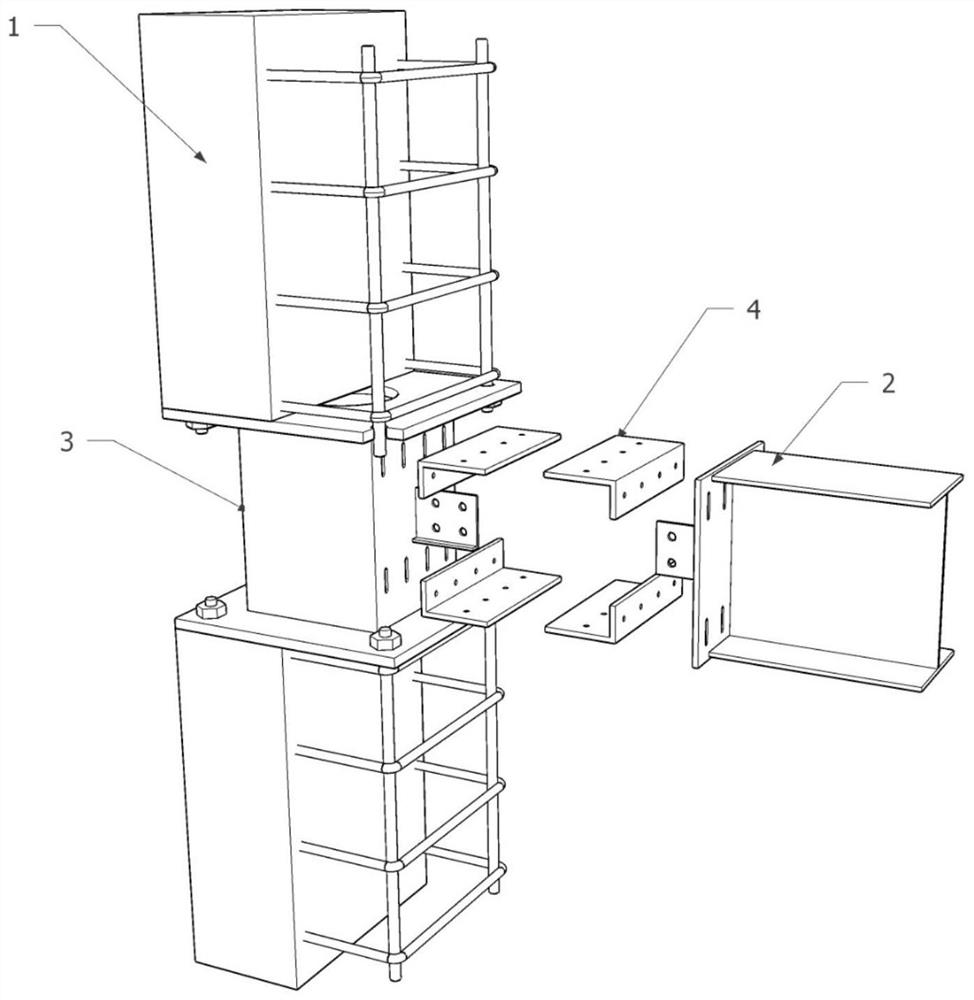

[0037] Such as figure 1 , 2 , a detachable modular beam-column joint device, including a joint standard part 3 and a connection standard part 4 for connecting a reinforced concrete column 1 to an H-shaped steel beam 2, the H-shaped steel beam includes H-shaped steel 2.1, and a beam connecting plate 2.2 And the web steel plate 2.3 is connected by welding; the node standard part 3 includes the node steel pipe 3.1, the L-shaped steel 3.2 and the node connection plate 3.3 are connected by welding. The joint standard part 3 and the connection standard part 4 connecting the reinforced concrete column 1 and the H-shaped steel beam 2 are connected by bolts.

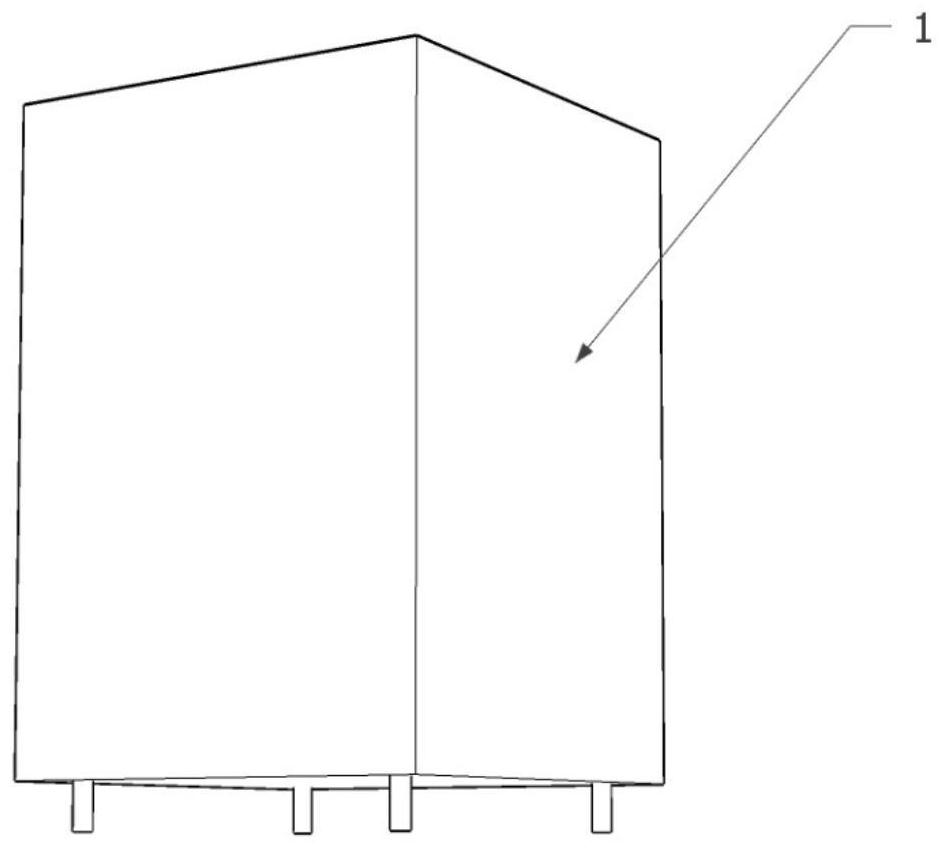

[0038] Such as image 3 , the reinforced concrete column 1 is a prefabricated component, and its steel bars protrude from the concrete surface to a certain length.

[0039] Such as Figure 4 The H-shaped steel beam 2 includes H-shaped steel 2.1, the beam conne...

Embodiment 2

[0041] Embodiment 2: A detachable modular beam-column joint device and construction method

[0042] Such as figure 1 , 2 , when the reinforced concrete column 1, the H-shaped steel beam 2, the node standard part 3 and the connection standard part 4 are prefabricated respectively in embodiment 1, the nodes are assembled, and the reinforced concrete column 1 and the node standard part 3 are bolted, The H-shaped steel beam 2 is bolted to the node standard part 3 through the connection standard part 4 .

[0043] Such as figure 2 , 3 , 5. When the reinforced concrete column 1 is connected with the node standard part 3, the reinforced concrete column 1 protrudes from the steel bar and extends into the hole reserved in the node connecting plate 3.3 and is connected by bolts.

[0044] Such as figure 2 , 4 , 6. When the H-shaped steel beam 2 is connected with the joint standard part 3 through the connection standard part 4, first connect several connection standard parts 4 with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com