High-voltage device for double-flow system rail transit vehicle

A technology for rail transit vehicles and high-voltage devices, applied in the field of rail transit, can solve problems such as the inability to guarantee the safety performance, the inability to obtain electricity from the pantograph, and the inability to adapt to the electrical requirements of the dual-stream system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following is further described in detail through specific implementation methods:

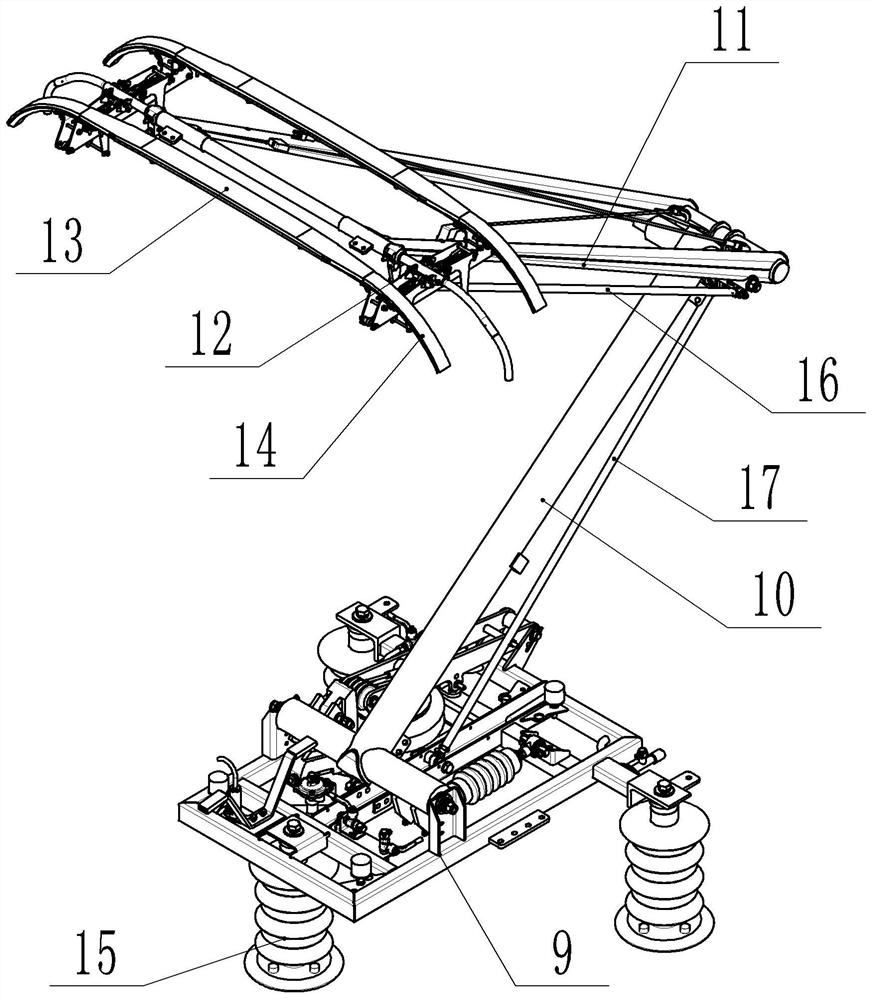

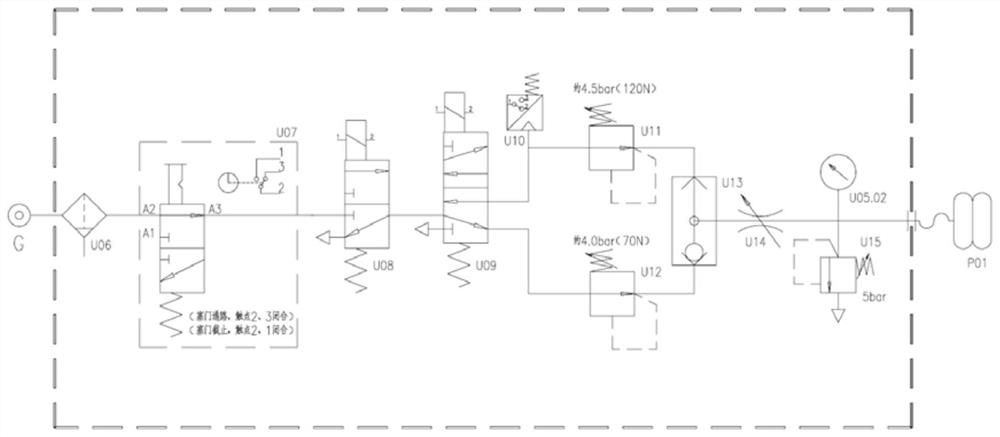

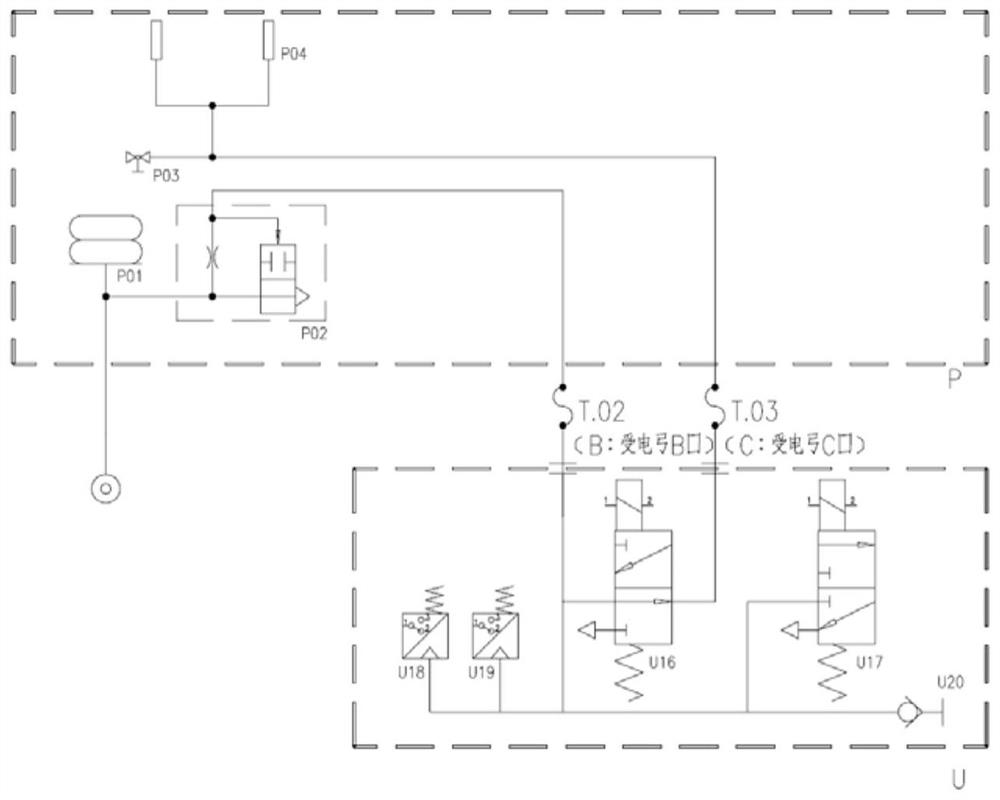

[0029] The reference signs in the drawings of the description include: high voltage cable 1, rigid terminal 2, half clip 3, flange 4, gasket 5, sealing ring 6, label 7, sealing cap 8, chassis assembly 9, lower arm assembly 10. Upper arm assembly 11, bow head assembly 12, bow head 13, bow angle 14, insulator 15, upper guide rod 16, lower guide rod 17, box body 18, box cover 19, hydraulic rod 20, vacuum circuit breaker 21, AC DC voltage transformer 22, filter U06, electric signal plate plug door U07, bow solenoid valve U08, electromagnetic reversing valve U09, third pressure switch U10, first precision pressure regulating valve U11, second precision pressure regulating valve U12 , Shuttle valve U13, Throttle valve U14, Safety valve U15, Air bag P01, Rapid lowering valve P02, ADD test valve P03, Slider P04, ADD fault recovery valve U16, Rapid exhaust valve U17, First pressure switch U18...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com