Vertical high-pressure casting machine

A high-pressure casting, vertical technology, applied in cleaning methods, chemical instruments and methods, cleaning methods and utensils using gas flow, etc., can solve the problems of energy loss, easy accumulation of impurities, inability to fully utilize heat, etc. Effectiveness of utilization and improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

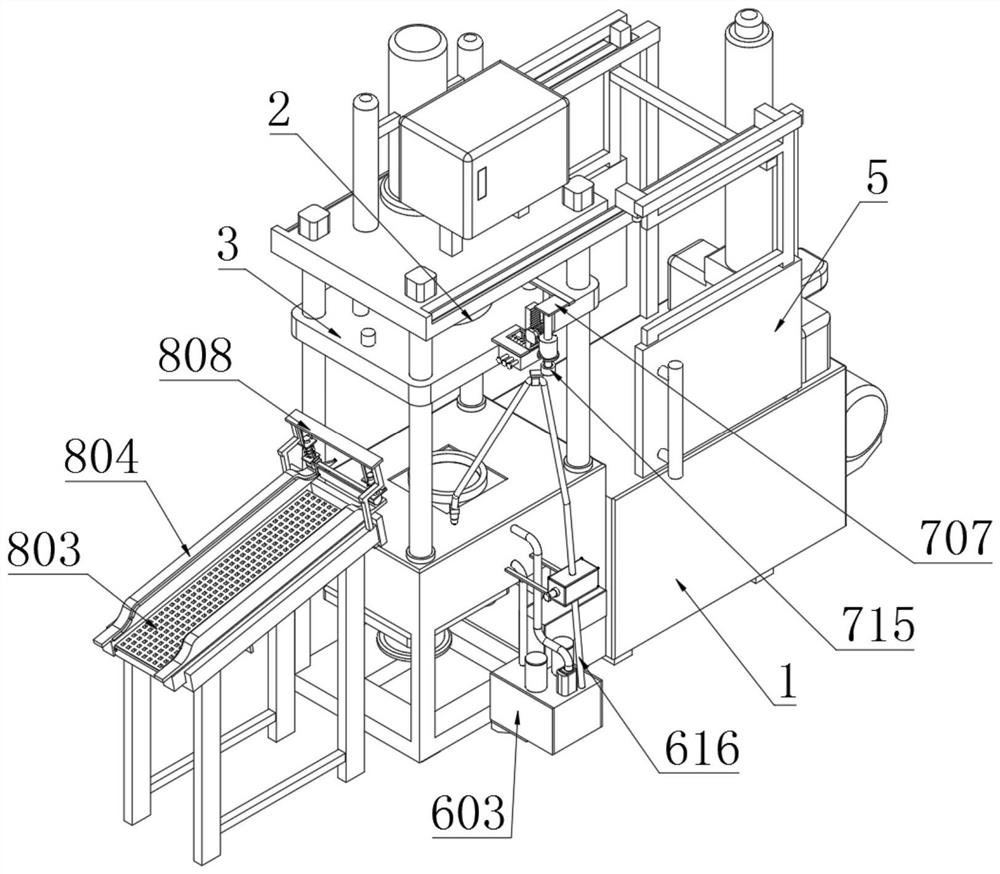

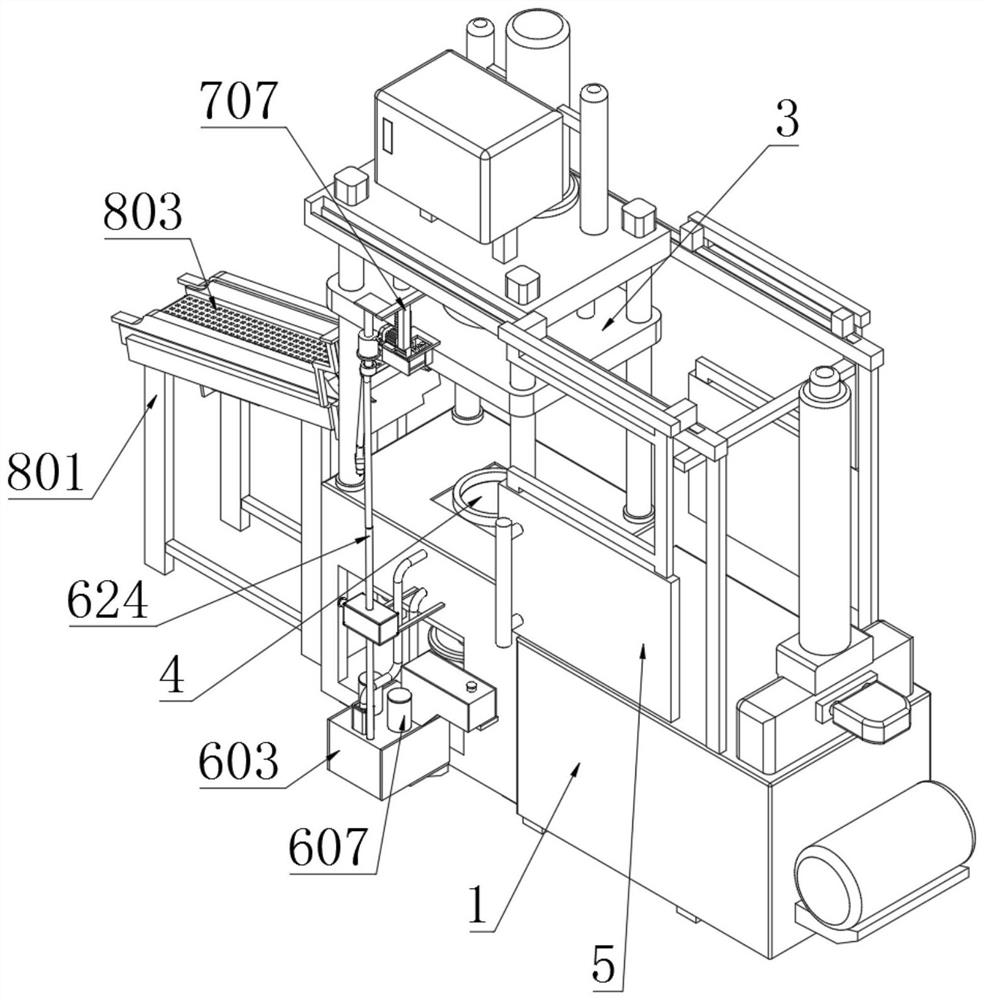

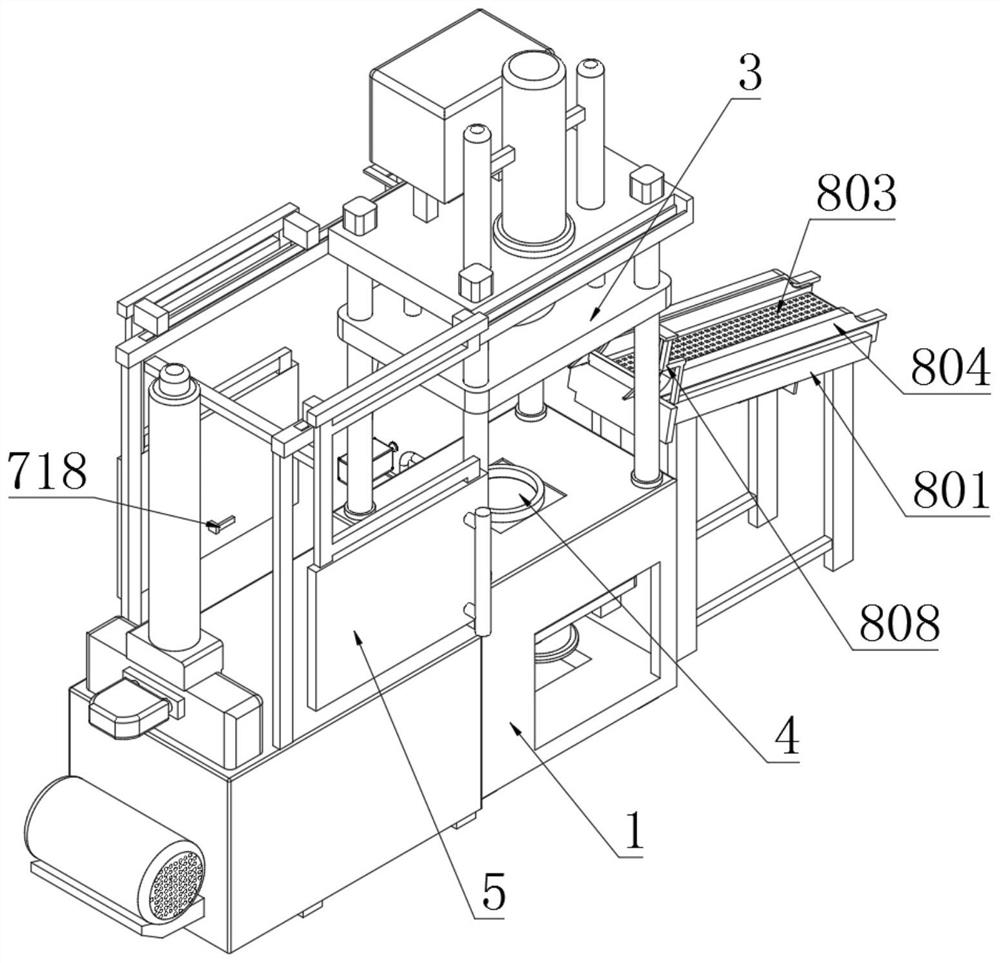

[0036] Example: such as Figure 1-10 As shown, the present invention provides a technical solution, a vertical high-pressure casting machine, including a body 1, a driving mechanism 2 is fixedly installed on the top of the body 1, a lifting plate 3 is fixedly connected to the bottom of the driving mechanism 2, and the body 1 The middle part of the body is located below the lifting plate 3, and a pressure chamber 4 is opened. The two sides of the body 1 are slidingly installed with moving doors 5, and the bottom of the body 1 is fixedly installed with a steam cleaning mechanism 6, which uses the heat generated by casting to pressurize the evaporation. The water inside the box 603 is heated and evaporated to increase the pressure, and the airflow generated by storage is discharged by using the exhaust pipe 624, which plays a role in cleaning;

[0037] The steam cleaning mechanism 6 includes a heat-absorbing chamber 601, an oil outlet pipe 602, an evaporation pressurization box 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com