Method for eliminating edge warping of silicon steel and silicon steel

A technology of edge and silicon steel, which is applied to the silicon steel produced by this method, eliminates the edge warping of silicon steel, and can solve the problems of silicon steel edge warping, reduce side pressure and width, and eliminate edge warping problems, the effect of improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

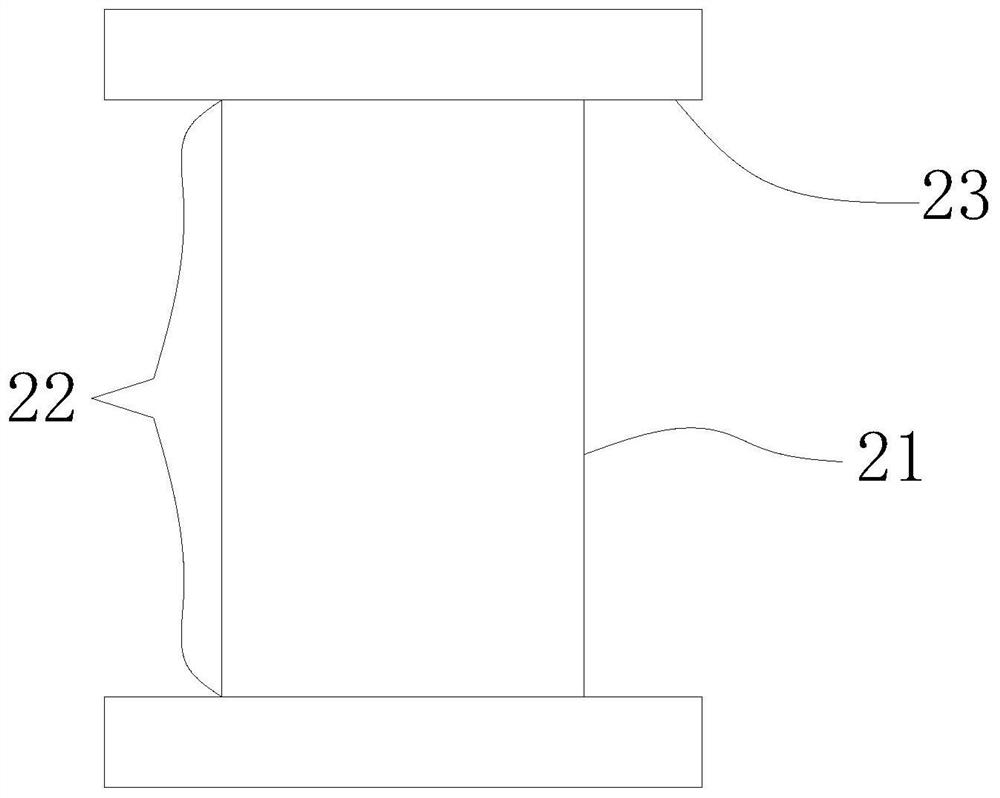

Image

Examples

Embodiment

[0036] Import the method of eliminating silicon steel edge warping of the present invention into the 1450 hot rolling and 1420 cold rolling production lines of a certain factory:

[0037] Batch production of 42 volumes of 50W600, the finished silicon steel specification is 0.5*1230mm, and the relevant process parameters of the hot rolling process are:

[0038] (1) Pretreatment of slabs with problems such as edge slump defects, corner crack defects, trapezoidal defects, edge burrs, etc.;

[0039] (2) The time for the slab to preheat in the heating furnace is 40 minutes;

[0040] (3) Side pressure reduces width by 10mm

[0041] (4) Increase the width of the side pressure portion of the side pressure vertical roller to 300mm;

[0042] (5) The R1 rolling mill does not descale, and the R2 rolling mill descales in the second pass;

[0043] (6) The work rolls of the R2 rolling mill will be replaced twice a week;

[0044] (7) The second side pressure vertical roller E2 is equipped...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com