A kind of flame-retardant phase change energy storage microcapsule and preparation method thereof

A phase change energy storage and microcapsule technology, applied in microcapsule preparations, microsphere preparation, chemical instruments and methods, etc., can solve the problem of low crosslinking density of phase change microcapsule walls, difficult to control and reduce the free radical polymerization process. The energy storage density of phase change microcapsules can make up for the problems of flammability, easy industrial production and high packaging efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

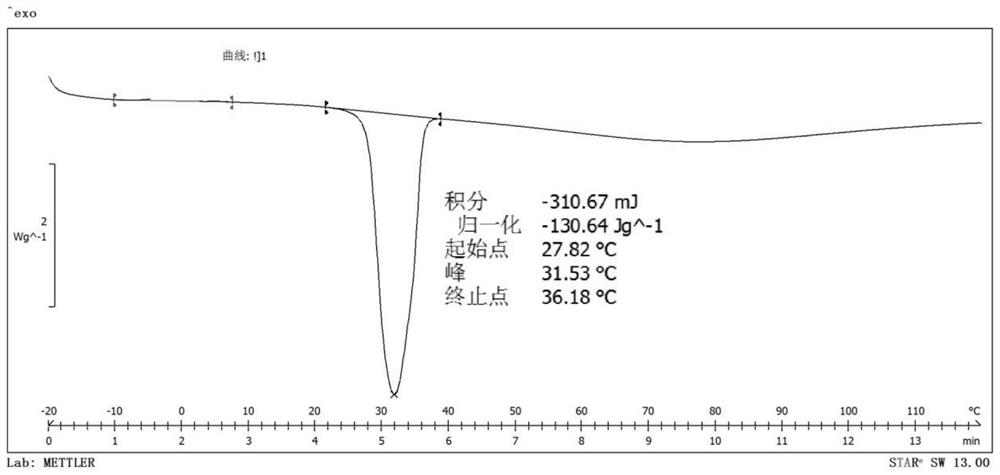

Embodiment 1

[0030] A method for preparing flame-retardant phase-change energy storage microcapsules, comprising the steps of:

[0031] S1. 1mol of N,N-bis(2-hydroxyethyl)aminomethylenephosphonic acid diethyl ester, 5mol of polypropylene glycol with a molecular weight of 2000, 2g of dibutyltin dilaurate and 10mol of isophorone diisocyanate were added to In a three-necked flask, heat up to 100° C. and stir for 1 h to obtain a polyurethane prepolymer terminated by isocyanate (-NCO) groups;

[0032] S2. After mixing 0.6Kg of the polyurethane prepolymer prepared in S1 with 1Kg of octadecane, add 3Kg of deionized water and 0.1Kg of sodium dodecylsulfonate, at 30°C and 10000r / min Stir for 10min to obtain a stable oil-in-water emulsion;

[0033]S3. Add 0.1 mol triethylenetetramine dropwise to the oil-in-water emulsion prepared in S2 within 5 minutes at a speed of 30°C and 100r / min, raise the temperature to 60°C and react for 0.5h, pump under reduced pressure Filter and wash with deionized water...

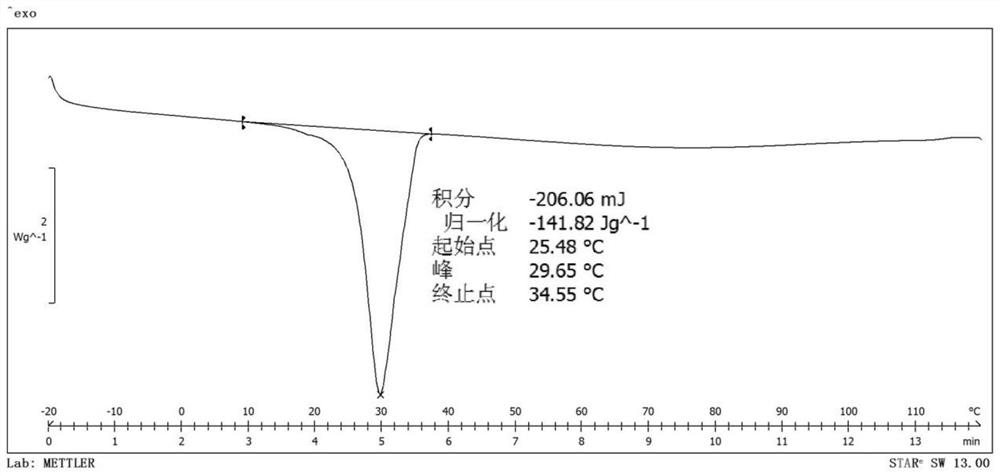

Embodiment 2

[0044] A method for preparing flame-retardant phase-change energy storage microcapsules, comprising the steps of:

[0045] S1. 1mol of N,N-bis(2-hydroxyethyl)aminomethylene phosphonic acid diethyl ester, 10mol of polytetrahydrofuran diol with a molecular weight of 1000, 5g of stannous octoate and 20mol of diphenylmethane diisocyanate were added to In a three-necked flask, heat up to 60° C. and stir for 4 hours to obtain a polyurethane prepolymer terminated by isocyanate (-NCO) groups;

[0046] S2. After mixing 0.5Kg of the polyurethane prepolymer prepared in S1 with 1Kg of octadecane, add 8Kg of deionized water and 0.01Kg of sodium dodecylbenzenesulfonate, at 40°C and 6000r / min Stir for 30min to obtain a stable oil-in-water emulsion;

[0047] S3. Add 0.2 mol of ethylenediamine dropwise to the oil-in-water emulsion prepared in S2 within 10 minutes at 40°C and a speed of 1000r / min, raise the temperature to 50°C for 2 hours, filter under reduced pressure and use The filter cake...

Embodiment 3

[0050] A method for preparing flame-retardant phase-change energy storage microcapsules, comprising the steps of:

[0051] S1. 1mol N,N-bis(2-hydroxyethyl)aminomethylene phosphonic acid diethyl ester, 1mol molecular weight is 2000 adipic acid series polyester diol, 3g organozinc and 3mol toluene diisocyanate In a three-necked flask, heat up to 70° C. and stir for 2 hours to obtain a polyurethane prepolymer terminated by isocyanate (-NCO) groups;

[0052] S2. After mixing 0.2Kg of the polyurethane prepolymer prepared in S1 with 1Kg of dodecanol, add 5Kg of deionized water, 0.03Kg of Tween-20 and 0.03Kg of Tween-80, at 25°C and a speed of 3000r / min Stir for 20 minutes under the same conditions to obtain a stable oil-in-water emulsion;

[0053] S3. Add 0.3mol 3,3'-dichloro-4,4'-diaminodiphenylmethane to the oil-in-water prepared in S2 within 30min under the conditions of 25°C and 500r / min. In the emulsion, the temperature was raised to 30° C. to react for 4 hours, filtered unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com