A method for determining the optimal nozzle size for volumetric fracturing wells with tight oil

A technology for volume fracturing and determination of methods, applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc. The effect of high production and stable production of oil wells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A method for determining the optimal nozzle size of a tight oil volume fracturing well, comprising the following steps:

[0058] (1) Analyze the productivity test data of well X1, the target horizontal well in the reservoir, and obtain the basic data of well X1. The results are shown in Table 1:

[0059] Table 1 Basic data of Well X1

[0060]

[0061]

[0062] The formation pressure described in Table 1 is obtained through the following sub-steps: According to the bottom hole flowing pressure and the liquid production rate, regression is obtained as follows figure 1 The IPR curve shown; the formation pressure is extrapolated from the IPR curve. It should be noted that the formation pressure can also be obtained by other methods in the prior art.

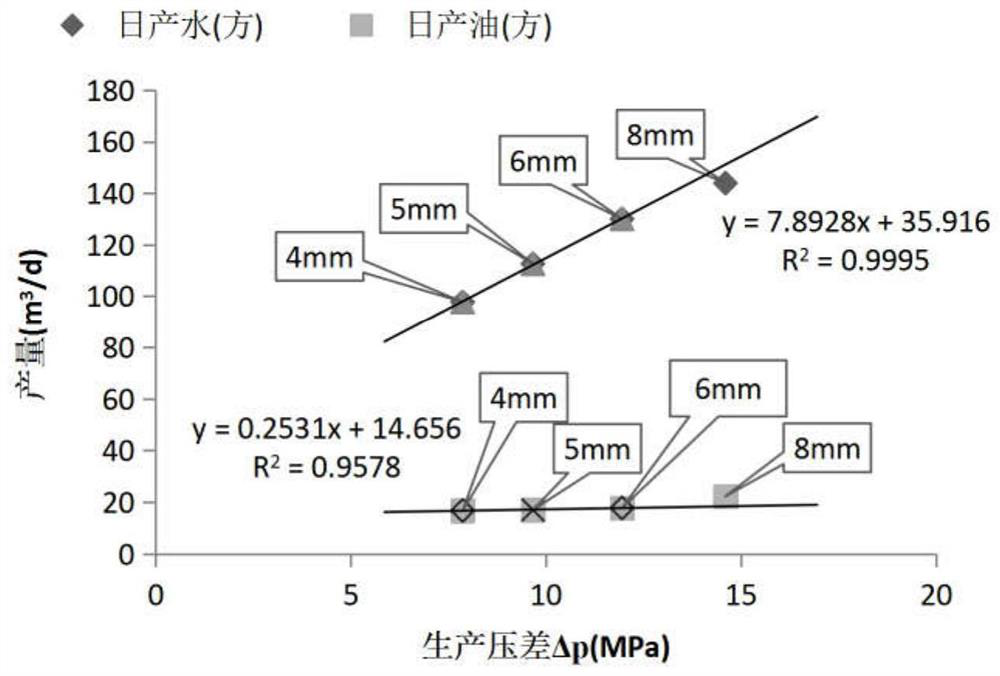

[0063] (2) According to the basic data, determine the reasonable choke size of the target well, specifically obtained through the following sub-steps: According to the production pressure difference, water production r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com