Anti-snaking shock absorber capable of realizing frequency-variable stiffness characteristic, joint and application

A technology of stiffness characteristics and shock absorbers, applied in the application of hydraulic rubber joints and joints, in the field of anti-snake shock absorbers, it can solve problems such as abnormal lateral vibration and insufficient lateral stability, reduce maintenance requirements, and improve lateral dynamics. The effect of learning performance and reducing operation and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

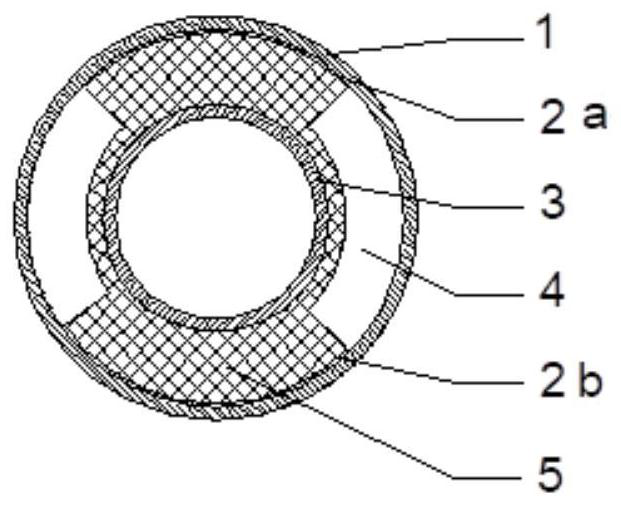

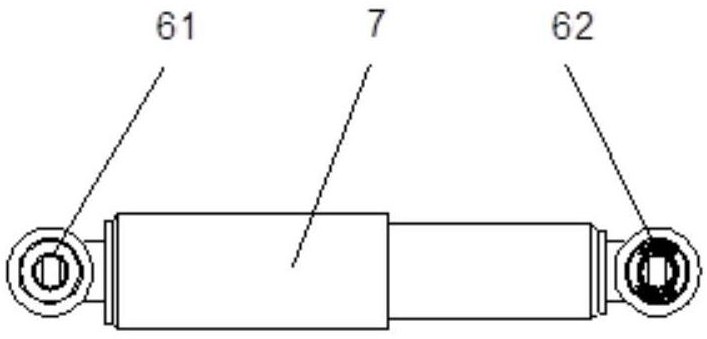

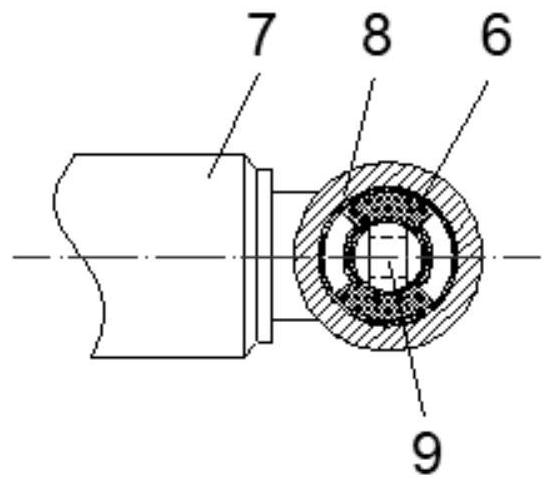

[0028] This embodiment provides an anti-snaking damper that can realize frequency-dependent stiffness characteristics, including: an oil anti-snaking damper 7, the two ends of the oil anti-snaking damper 7 are rod ends 8, and the left hydraulic rubber joint 61. The right hydraulic rubber joint 62 is respectively installed inside the rod end 8 at both ends of the oil anti-snake shock absorber 7, the connecting rod 9 is installed at the core of each hydraulic rubber joint, and the connecting rod 9 is fixed to the bogie or car body end ;The hydraulic rubber joint is cylindrical, including the outer metal jacket 1 and the inner metal jacket 3, the hydraulic chamber 4 is between the metal jacket 1 and the metal inner jacket 3, the main spring 5 is embedded in the hydraulic chamber 4, and the top of the main spring 5 The gap between the main spring 5 and the outer flow channel is the upper flow channel 2a, the gap between the bottom of the main spring 5 and the outer flow channel is ...

Embodiment 2

[0036] This embodiment provides a hydraulic rubber joint, which is installed inside the rod end 8 at both ends of the oil anti-snake shock absorber 7, the core of the hydraulic rubber joint is installed with a connecting rod 9, and the connecting rod 9 is fixed to the bogie or car body end; The hydraulic rubber joint is cylindrical, including the outer metal jacket 1 and the inner metal jacket 3. There is a hydraulic chamber between the metal jacket 1 and the metal inner jacket 3. The main spring 5 is embedded in the hydraulic chamber, and the top of the main spring 5 and the outer flow channel The gap between them is the upper flow channel 2a, the gap between the bottom of the main spring 5 and the outer flow channel is the lower flow channel 2b, and the left and right sides of the main spring 5 are hydraulic chambers 4.

[0037] The hydraulic rubber joint is made of rubber material, and the hydraulic cavity is an alcohol solution.

[0038] Two completely identical hydraulic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com