Resilient suspension mechanism of locomotive steering bogie driving device

The technology of a locomotive bogie and a driving device is applied in the direction of the device for lateral relative movement between the underframe and the bogie, which can solve the problems of deterioration of the lateral performance and aggravation of vibration of the locomotive, and achieve the effect of improving the lateral dynamic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

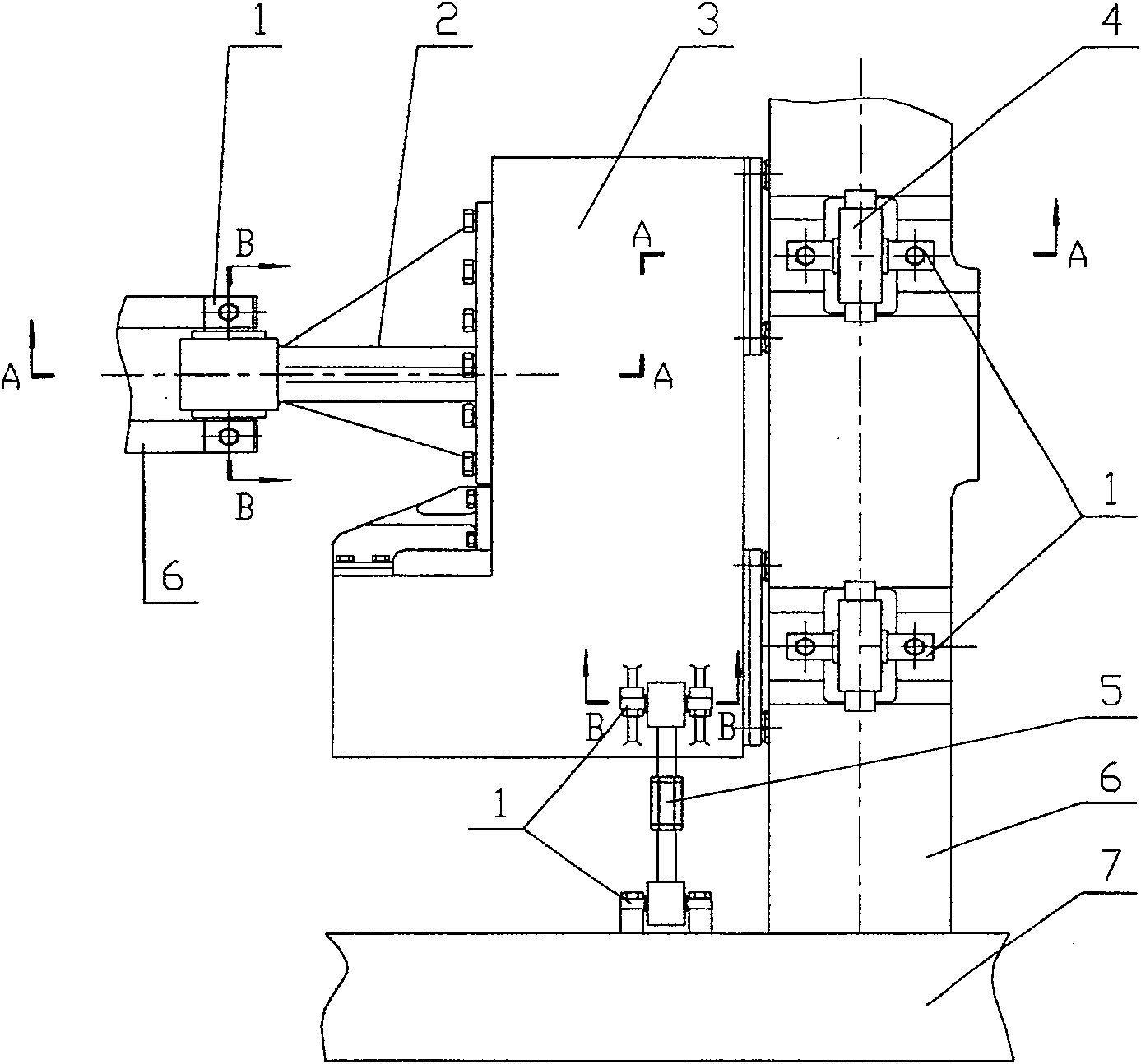

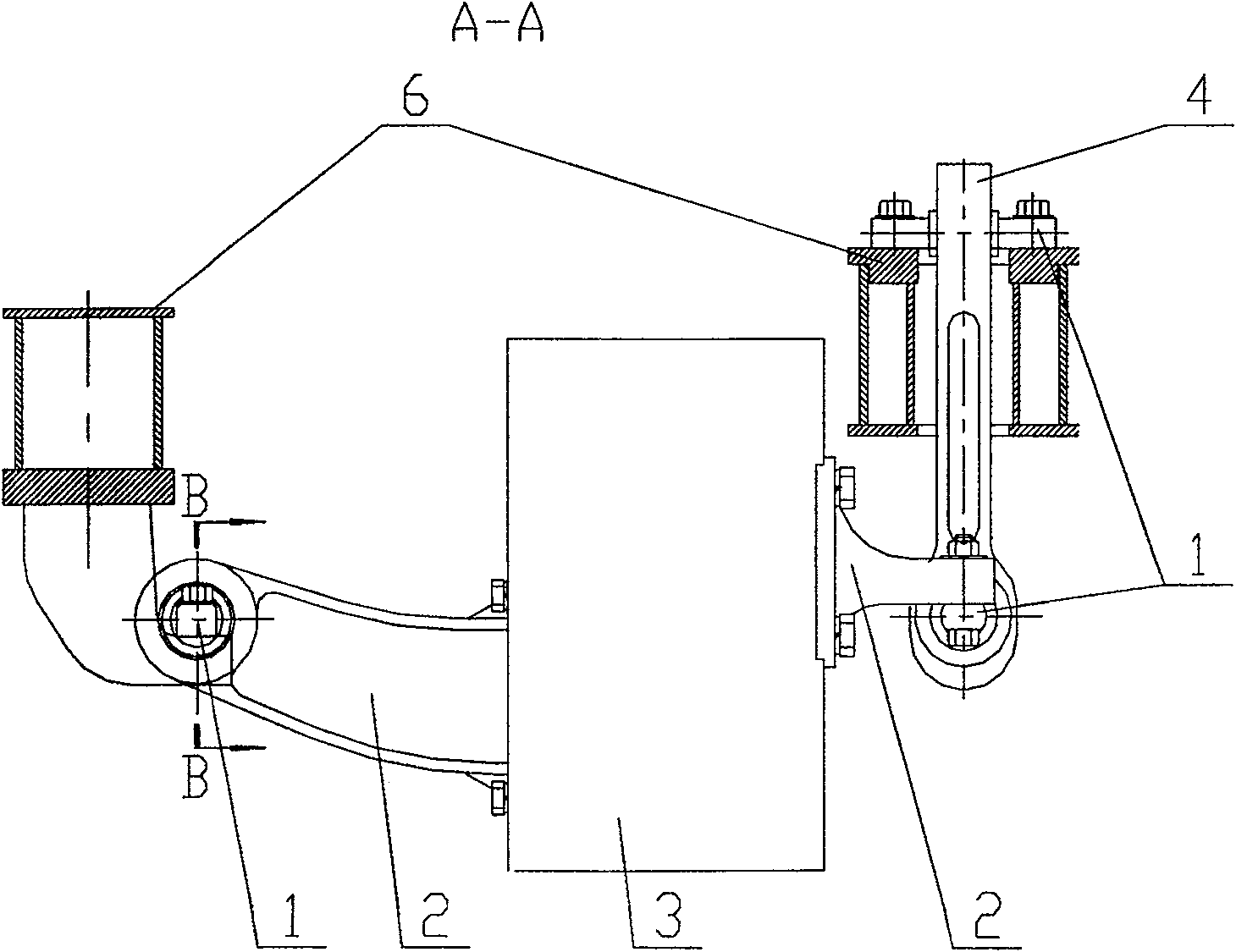

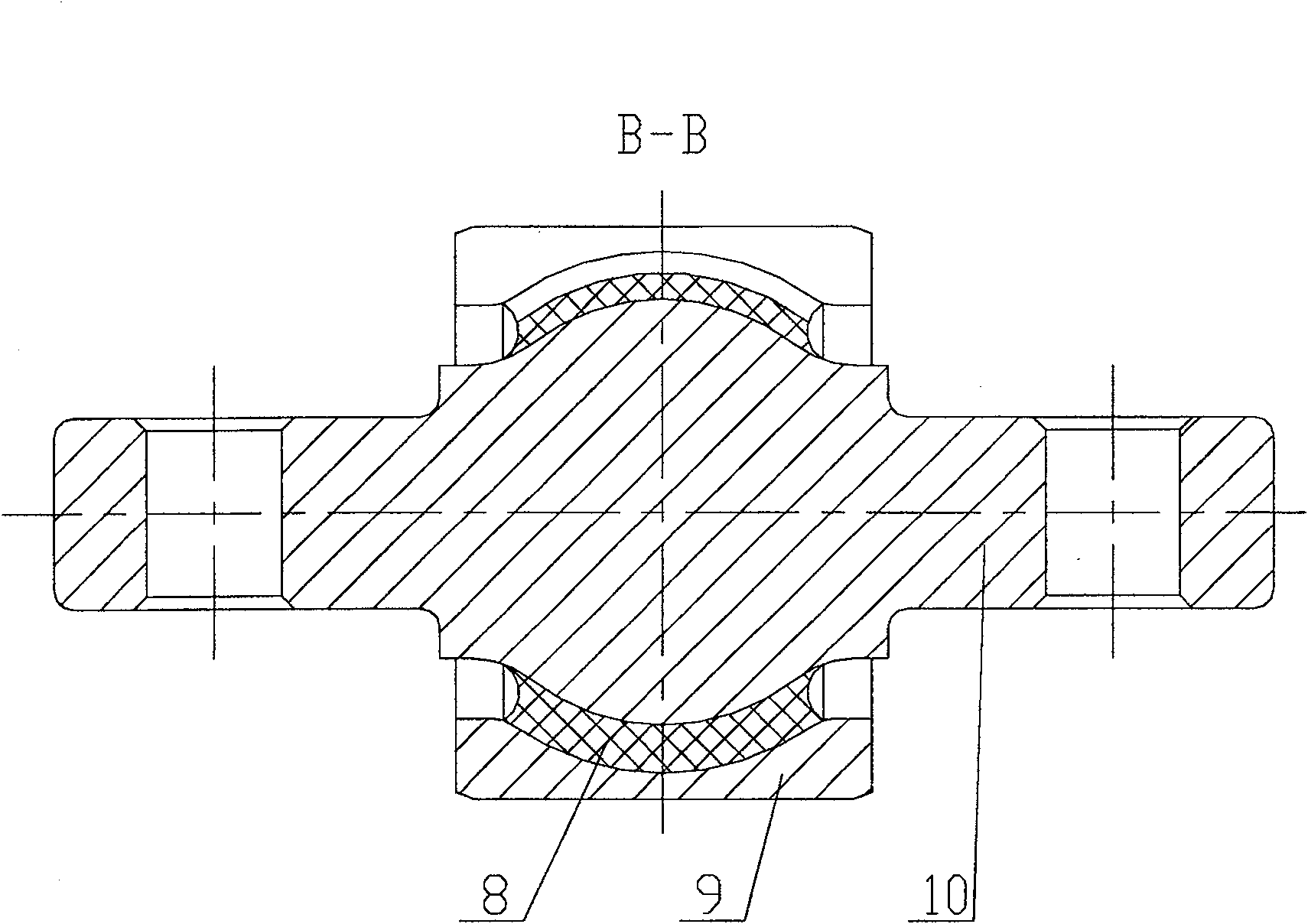

[0009] Referring to the accompanying drawings, the locomotive bogie driving device elastic suspension mechanism of the present invention, the motor and the gear box are rigidly connected to form an integral driving unit (3), and three suspension arms are arranged on the driving unit (3). (2). One end of the frame suspension arm (2) is rigidly fixed to the driving device unit (3) through bolts, the other end of the front suspension arm (2) is connected with the corresponding frame beam (6) through a rubber ball joint (1), and the two rear The other end of the boom (2) is hung on the corresponding frame beam (6) through the rubber ball joint (1) and the boom (4). The rubber ball joint (1) is composed of three parts: a mandrel (10), a jacket (9), and a rubber layer (9). Mandrel (10), overcoat (9) are all steel parts. Since the two parts connected by the rubber ball joint (1) can have certain axial displacement and deflection displacement. Therefore, the front hanging point of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com