Reinforced light steel keel partition wall installation and construction method

A technology of light steel keel and construction method, which is applied in the treatment of walls, building materials, construction, etc., can solve the problems of reducing the quality and efficiency of wall panel installation, low installation efficiency, and high risk, and improve the installation efficiency and quality. , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

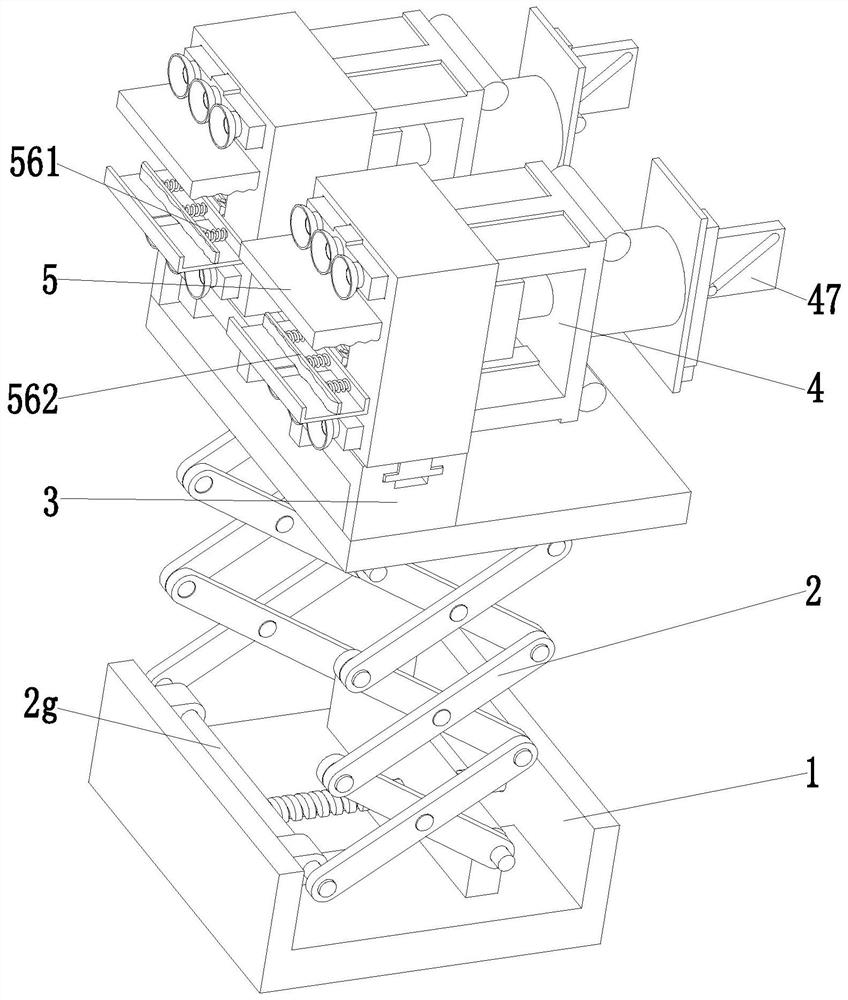

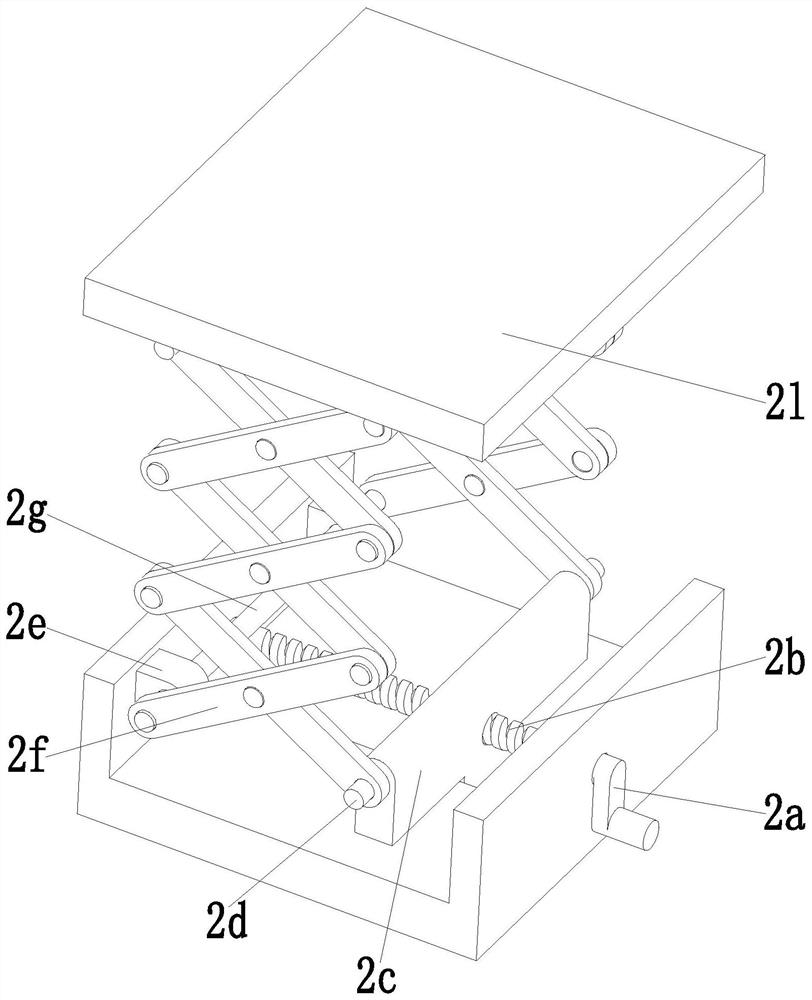

[0037] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

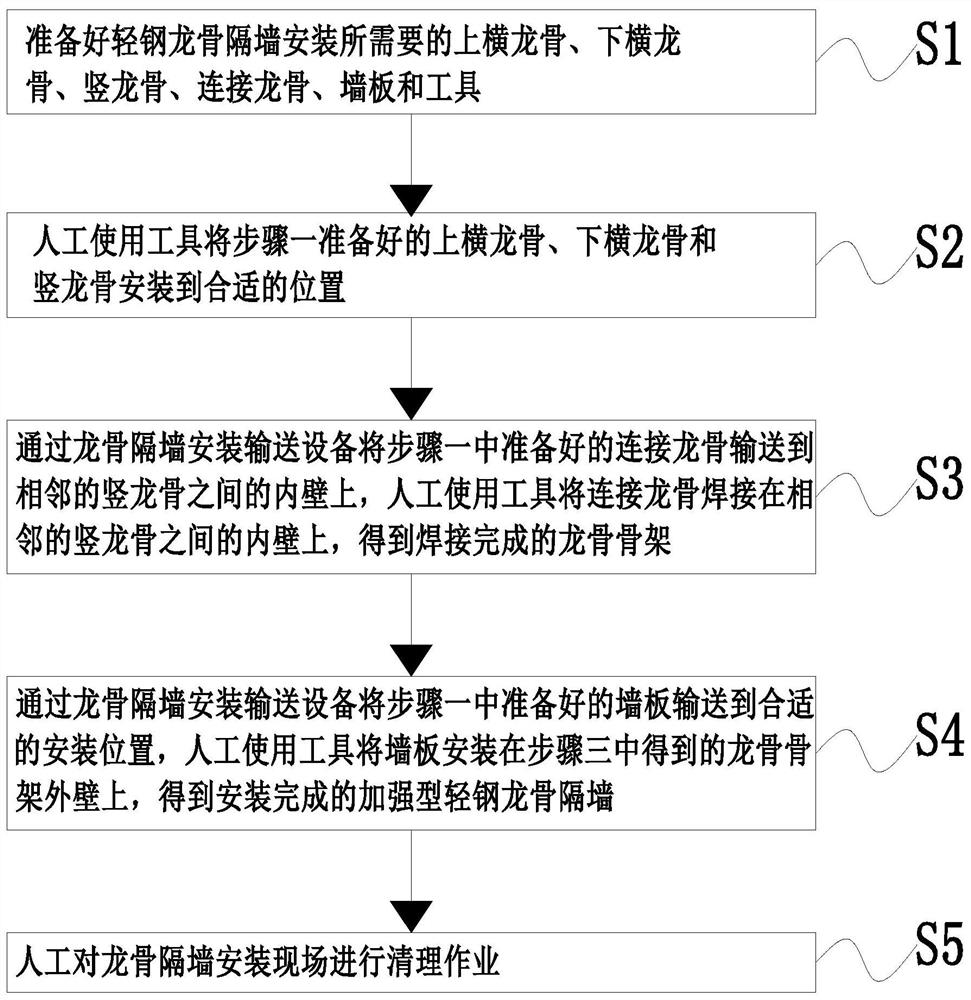

[0038] like Figure 1 to Figure 11 As shown, a reinforced light steel keel partition wall installation and construction method mainly includes the following steps:

[0039] Step 1, material preparation, prepare the upper horizontal keel, lower horizontal keel, vertical keel, connecting keel, wall panels and tools required for the installation of the light steel keel partition wall;

[0040] Step 2, installation work, manually use tools to install the upper horizontal keel, lower horizontal keel and vertical keel prepared in step 1 to a suitable position;

[0041] Step 3, material conveying, the connecting keel prepared in step 1 is transported to the inner wall between adjacent vertical keels through the installation of conveying equipment on the k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com