Steel springboard fixing support and scaffold

A technology for fixing brackets and scaffolding, which is applied in the connection of scaffolding, the attachment of scaffolding, the support of house structure, etc., can solve the problems of poor erection effect of steel springboards, slipping and shaking, hidden dangers, etc., and saves construction time and installation methods. Convenience and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

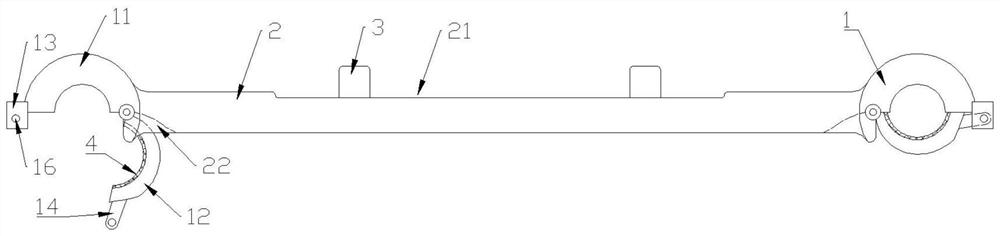

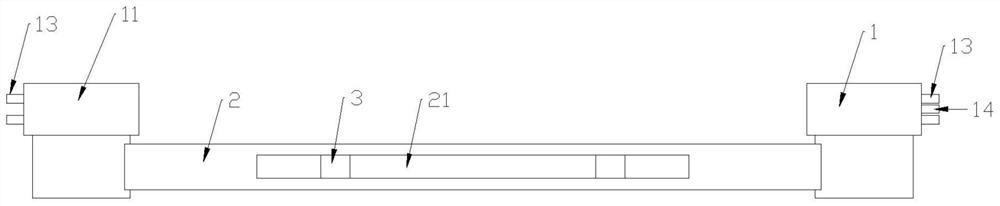

[0040] A steel springboard fixing bracket, the steel springboard is easy to install, can effectively fix the steel springboard, saves the installation period and improves the use safety of the steel springboard, such as figure 1 , figure 2 , image 3 , Figure 4 As shown, specifically set to the following structure:

[0041] This kind of steel springboard fixing bracket includes a steel pipe holding card 1 and a connecting cross bar 2;

[0042]Specifically, the steel pipe holding card 1 includes a holding card main body 11 , a valve 12 , a lock head 13 and a dead bolt 14 . The main body 11 for holding the card is roughly a semi-circular structure, the bottom of which has a semi-circular groove with a notch downward, and the outer side of the main body 11 for holding the card is fixedly connected with a lock head 13 . The valve 12 is roughly a semi-circular structure, and its top has an arc groove with a notch upward, and the arc groove is larger than the semicircle groove...

Embodiment 2

[0047] This embodiment is further optimized on the basis of the above-mentioned embodiments, further to better realize the present invention, especially adopt the following configuration structure:

[0048] The top of the connecting cross bar 2 is provided with a concave flat groove 21, and a vertically protruding stopper 3 is fixedly connected in the flat groove 21, and the height of the stopper 3 is greater than the groove depth of the flat groove 21 and The sum of the plate thicknesses of steel springboards. The limit protrusion 3 is used to pass through the limit hole provided on the steel springboard 6 to limit it longitudinally, so as to improve the use safety of the steel springboard.

[0049] Preferably, the quantity of the limiting protrusions 3 is set to be multiple, and all the limiting protrusions 3 are arranged in sequence along the length direction of the connecting cross bar 2 .

Embodiment 3

[0051] This embodiment is further optimized on the basis of the above-mentioned embodiments, further to better realize the present invention, especially adopt the following configuration structure:

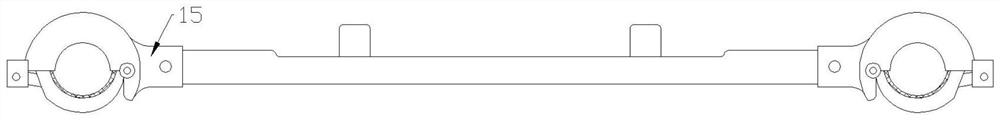

[0052] The inner side of the holding card main body 11 is welded with a transverse intubation tube 15, the intubation tube 15 has a pin hole 16 penetrating in its radial direction, the end of the connecting cross bar 2 has a through hole aligned with the pin hole 16, and the connecting cross bar 2 It is detachably inserted into the cannula 15 at the corresponding end and passed through the bolt for fixing. In this way, the setting of the intubation tube 15 can be used for plugging and connecting the cross bar 2, and the steel springboard fixing bracket can be disassembled into a steel pipe holding card 1 and the connecting cross bar 2 when not in use. The cross bar 2 realizes the versatility among scaffolds of different widths.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com