Environment-friendly rapid treatment equipment for compound fertilizer waste liquid

A technology of compound fertilizer and treatment equipment, which is applied in the fields of filtration treatment, natural water treatment, light water/sewage treatment, etc. It can solve the troublesome problems of waste liquid treatment and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

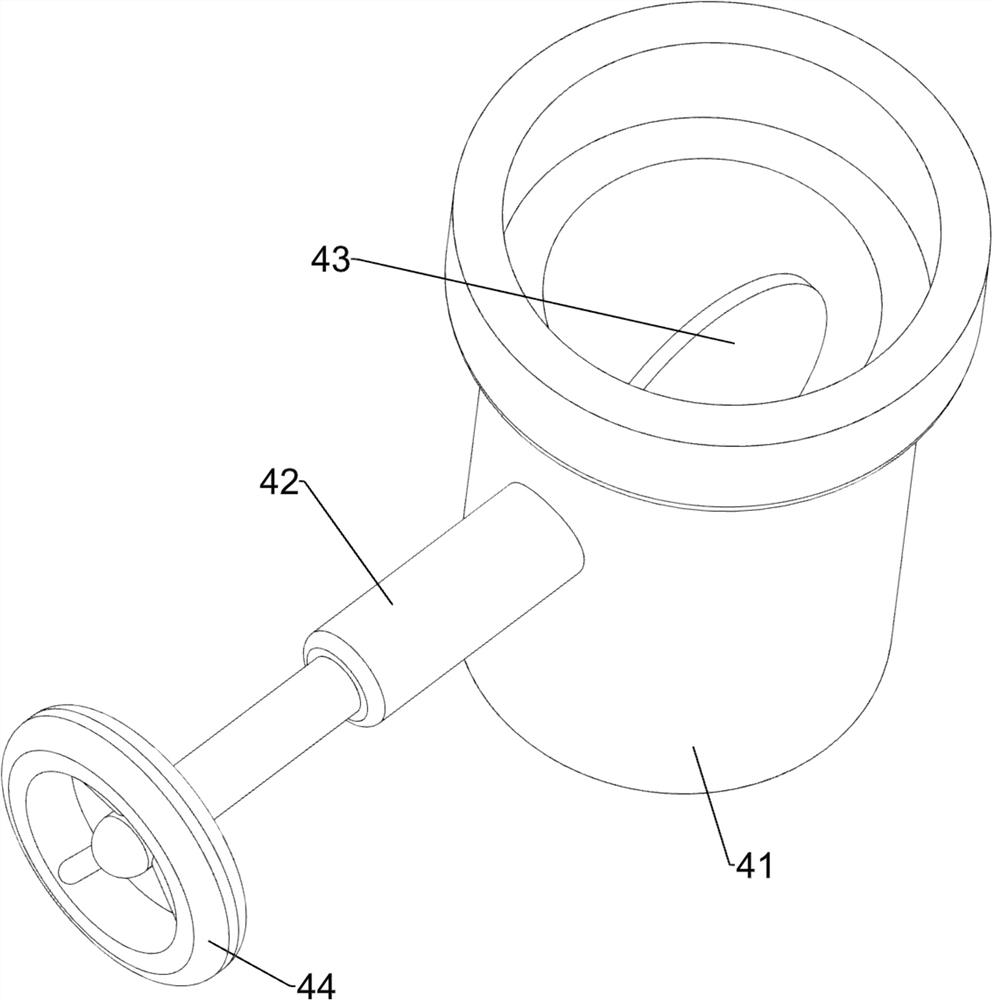

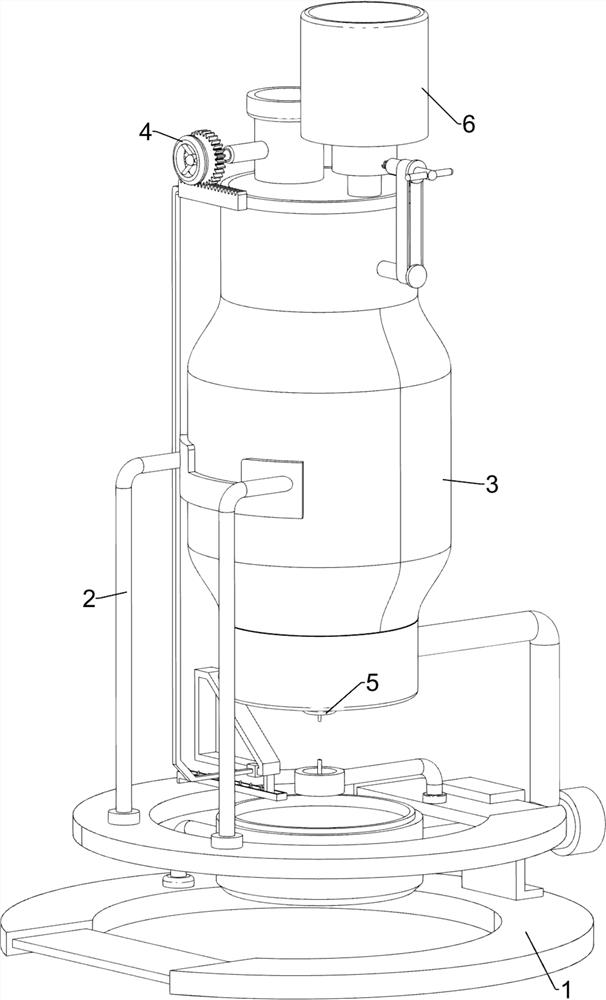

[0027] An environmentally friendly compound fertilizer waste liquid rapid treatment equipment, such as Figure 1-4 As shown, it includes a support frame 1, a first fixed frame 2, a box body 3, a blanking assembly 4, a filter assembly 5 and a disinfection assembly 6, and the left side of the support frame 1 is connected with a first fixed frame 2, and the first fixed frame 2 The box body 3 is fixedly connected with the box body 3 by bolts, the box body 3 is provided with a box door, the top of the box body 3 is provided with a blanking assembly 4, the inside of the box body 3 is provided with a filter assembly 5, and the box body 3 top is provided with a disinfection assembly 6.

[0028] When it is necessary to filter the compound fertilizer waste liquid, the compound fertilizer waste liquid can be intermittently entered into the box body 3 through the feeding assembly 4, and then the compound fertilizer waste liquid is filtered by the filter assembly 5, while the disinfection a...

Embodiment 2

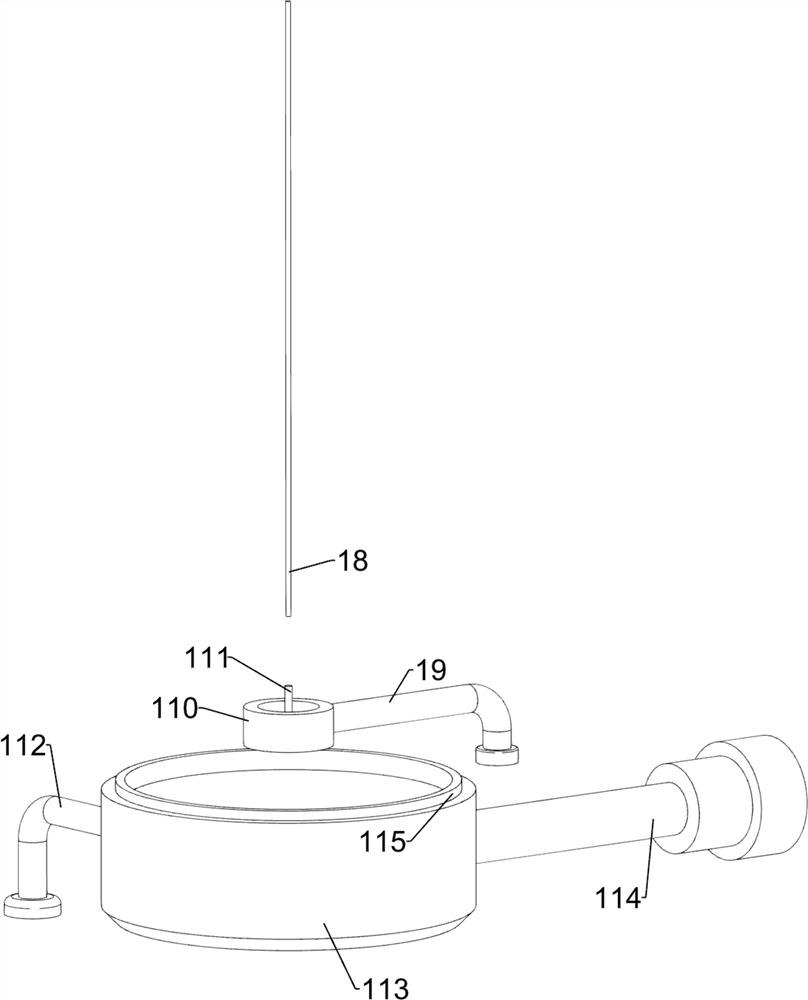

[0036] On the basis of Example 1, such as image 3 , Figure 5 , Figure 6 and Figure 7As shown, it also includes a first contact rod 7, a slide rail 8, a slide block 9, a wedge block 10, a third spring 11, a connecting frame 12, a rack 13 and a gear 14, and the bottom of the slide rod 52 is connected with the first contact rod 7. The rear side of the support frame 1 is fixedly connected with a slide rail 8 by bolts. A slide block 9 is slidably arranged on the slide rail 8. A wedge block 10 is connected to the upper part of the slide block 9. The wedge block 10 cooperates with the first contact rod 7 to slide The third spring 11 is connected between the block 9 and the slide rail 8, the left side of the wedge-shaped block 10 is connected with a connecting frame 12, the top of the connecting frame 12 is connected with a rack 13, the key on the first rotating shaft 42 is connected with a gear 14, and the gear 14 and The rack 13 meshes.

[0037] When the slide bar 52 moves d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com