Cylindrical pipeline cleaning equipment

A pipe cleaning, cylindrical technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of poor cleaning effect and large floor space, so as to speed up the flow rate of water and improve work efficiency Efficiency, enhanced cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

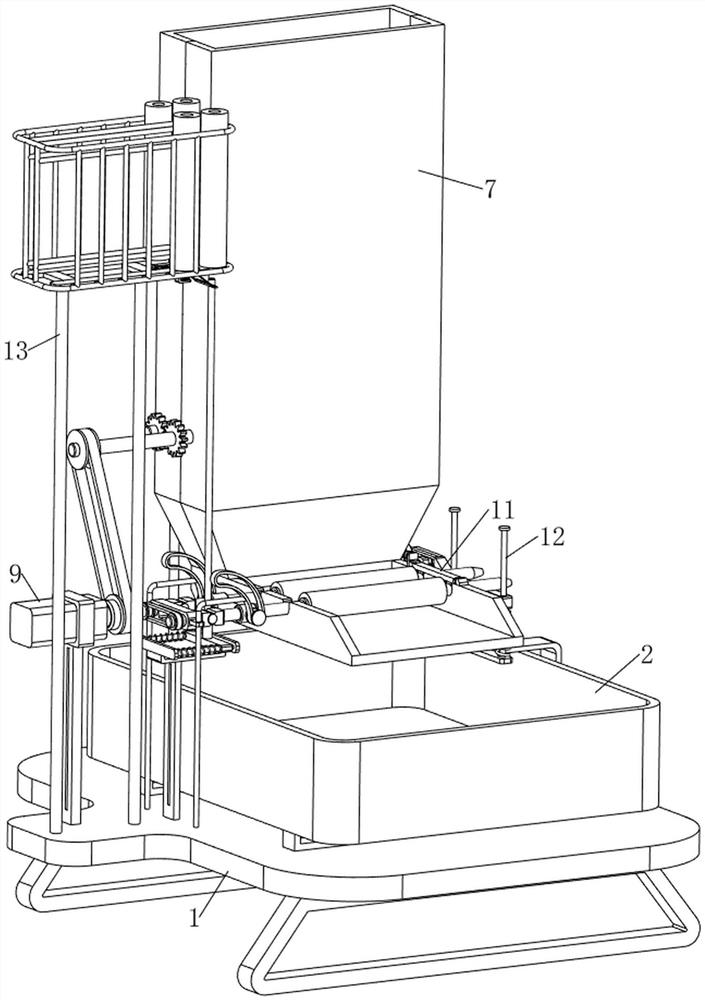

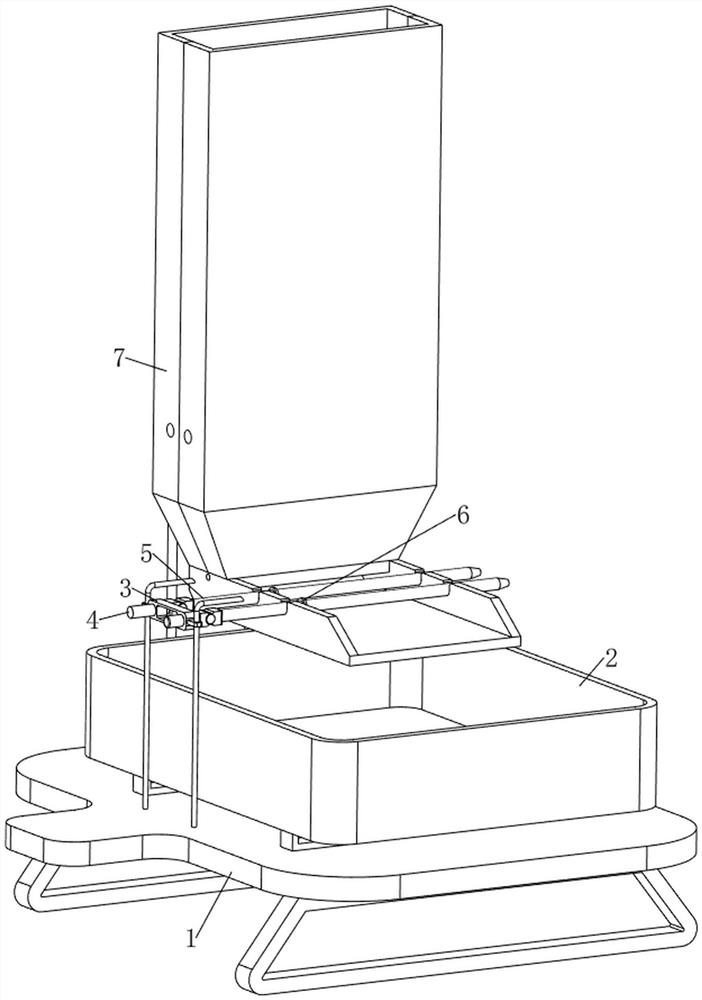

[0070] A cylindrical pipe cleaning equipment, such as Figure 1-Figure 5 As shown, it includes a bottom plate 1, a collection frame 2, a first support frame 3, a first rotating shaft 4, a placement column 5, a fixing ring 6, a water tank 7, a water discharge mechanism 8 and a rotating mechanism 9, and the top of the bottom plate 1 is provided with a collection frame 2 , a first support frame 3 is arranged in the middle of the front side of the top of the bottom plate 1, the upper part of the first support frame 3 is symmetrically arranged with a first rotating shaft 4, and the rear side of the first rotating shaft 4 is rotatably provided with a placing column 5, and the placing column 5 A fixing ring 6 is provided on the front side, a water tank 7 is provided in the middle of the top left side of the bottom plate 1, the placing column 5 is in contact with the water tank 7, a water discharge mechanism 8 is provided at the lower part of the water tank 7, and a rotating mechanism ...

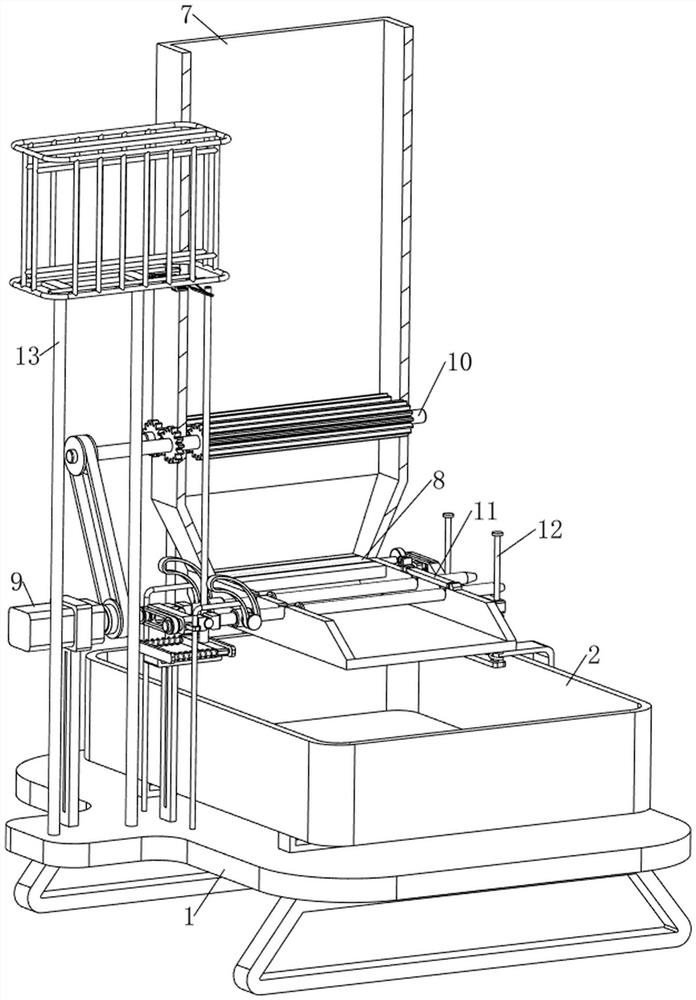

Embodiment 2

[0075] On the basis of Example 1, as Figure 6-Figure 10 As shown, it also includes a pressing mechanism 10. The pressing mechanism 10 includes a fourth rotating shaft 1000, a roller 1001, a transmission belt 1002, a full gear 1003 and a pressing gear 1004. The lower part of the water tank 7 is provided with a fourth rotating shaft 1000 symmetrically rotating left and right. , the fourth rotating shaft 1000 is located above the second rotating shaft 80 , the front side of the fourth rotating shaft 1000 on the right side and the rear side of the third rotating shaft 92 are provided with rollers 1001 , a transmission belt 1002 is wound between the rollers 1001 , and the front side of the fourth rotating shaft 1000 All gears 1003 are provided with all gears 1003 meshing with each other, and pressurizing gears 1004 are provided on the fourth rotating shaft 1000 .

[0076] When people start the motor 91 , the output shaft of the motor 91 drives the third rotating shaft 92 to rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com